Ok, so I've been having a nightmare with 'air' in the heating system and also pumping-over.

Originally the pipe layout was like this;

Boilerflow coming up the left hand side, vent pipe to the loft continuing up, the main flow turning horizontal. Then a T to the 15mm feed, and then carrying on down to the pump.

With this arrangement I was unable to fill the system at a point in the past as the feed had blocked. Also as the short horizontal section of feed pipe just after the T wasn't quite horizontal it seemed quite common to get an airlock in there

I then changed the top half of the loop and re-ran the feed as this;

Changing the feed to an angled section of pipe has removed the problem of getting airlocks in the feed, but I still get air bubbling UP the feed rather than the vent, and also (I think) am getting air sucked into the system via the vent pipe

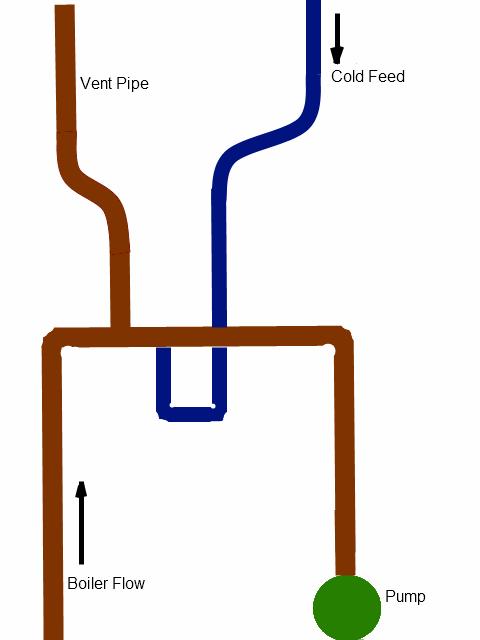

As a final attempt I am planning to change it again, incorporating some 'features' that I have seen used elsewhere.

Comments please on whether ( a ) you'd expect it to fix the problems, and ( b ) whether you would do anything differently;

I believe that;

- Taking the VENT from the horizontal section rather than from the vertical 'straight-on' route that it currently is should help to stop the water pumping over into the F/E tank in the loft.

- Having an inverted loop in the feed pipe should stop air trying to travel up this pipe to get out of the system, whilst still allowing the feed to operate correctly. I would imagine that this 'might' be more suseptible to blockages, but if I keep the system clean, and perhaps do the loop with compression fittings to allow removal if need be it shouldn't be too much of an issue?

In addition to the above, is it advisable to fit an air seperator such as this;

I have heard that they too can be prone to blocking though?

If it is advisable to fit one, please advise which way to fit it! I would think that the feed from the boiler would enter at the side on the highest point, and then exit from the lower point which should be clear of air? (the air bubbling out through the vertical port), but I might have the entry and exit the wrong way around for reasons I cannot think of?

Lastly, if it is advised to fit an air seperator would a better solution be to fit one like this, which includes the cold feed connection point;

Not that I can really see a benfit to that, other than it saves using a seperate T after the seperator?

Many many thanks!

Originally the pipe layout was like this;

Boilerflow coming up the left hand side, vent pipe to the loft continuing up, the main flow turning horizontal. Then a T to the 15mm feed, and then carrying on down to the pump.

With this arrangement I was unable to fill the system at a point in the past as the feed had blocked. Also as the short horizontal section of feed pipe just after the T wasn't quite horizontal it seemed quite common to get an airlock in there

I then changed the top half of the loop and re-ran the feed as this;

Changing the feed to an angled section of pipe has removed the problem of getting airlocks in the feed, but I still get air bubbling UP the feed rather than the vent, and also (I think) am getting air sucked into the system via the vent pipe

As a final attempt I am planning to change it again, incorporating some 'features' that I have seen used elsewhere.

Comments please on whether ( a ) you'd expect it to fix the problems, and ( b ) whether you would do anything differently;

I believe that;

- Taking the VENT from the horizontal section rather than from the vertical 'straight-on' route that it currently is should help to stop the water pumping over into the F/E tank in the loft.

- Having an inverted loop in the feed pipe should stop air trying to travel up this pipe to get out of the system, whilst still allowing the feed to operate correctly. I would imagine that this 'might' be more suseptible to blockages, but if I keep the system clean, and perhaps do the loop with compression fittings to allow removal if need be it shouldn't be too much of an issue?

In addition to the above, is it advisable to fit an air seperator such as this;

I have heard that they too can be prone to blocking though?

If it is advisable to fit one, please advise which way to fit it! I would think that the feed from the boiler would enter at the side on the highest point, and then exit from the lower point which should be clear of air? (the air bubbling out through the vertical port), but I might have the entry and exit the wrong way around for reasons I cannot think of?

Lastly, if it is advised to fit an air seperator would a better solution be to fit one like this, which includes the cold feed connection point;

Not that I can really see a benfit to that, other than it saves using a seperate T after the seperator?

Many many thanks!