Hi All

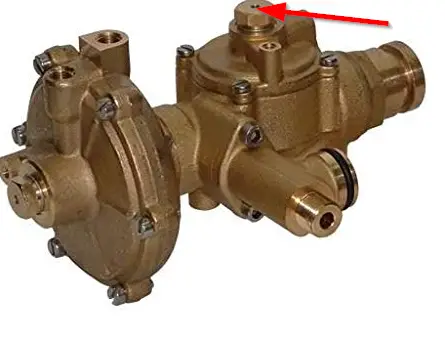

I have ordered a diverter valve repair kit and will be attempting this install tomorrow. I have successfully repaired the diverter valve front diaphragm last year. The arrow on the diagram indicates the current issue, the push rod does not move up and down successfully if pushed down then the dhw works for a while and then stops 24hrs later until pushed back down. What is this part called? and i'm assuming that once i take the whole thing out, i can follow the same process for the front diaphragm repair, removing the screws to gain access to the other push rod. Does anyone have an exploded view of that section to assist me?

I have ordered a diverter valve repair kit and will be attempting this install tomorrow. I have successfully repaired the diverter valve front diaphragm last year. The arrow on the diagram indicates the current issue, the push rod does not move up and down successfully if pushed down then the dhw works for a while and then stops 24hrs later until pushed back down. What is this part called? and i'm assuming that once i take the whole thing out, i can follow the same process for the front diaphragm repair, removing the screws to gain access to the other push rod. Does anyone have an exploded view of that section to assist me?