- Joined

- 27 Nov 2016

- Messages

- 8

- Reaction score

- 0

- Country

Hi,

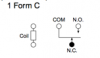

I have a fault on my boiler which is causing the Divert valve to continuously motor open/close with consequential impact on the CH and cycling hot/cold water when DHW demanded.

I have found 240v is permanently on the CLOSE terminal on the divert valve, when CH is demanded 240v is applied to the OPEN terminal but as power is still on the CLOSE terminal the actuator just continues to run OPEN - CLOSE as power is permanently applied to both sides.

I suspected the PCB so acquired another board (second hand but supposedly from a working boiler !) so either the 2nd PCB features the same problem (unlikely ??? but possible !!) or something else is preventing the CLOSE demand being switched off when CH is demanded.

DHW functions fine no CH demand and CH works fine if I isolate the divert valve actuator in the OPEN position by removing the moles connector.

Any ideas ?

I have a fault on my boiler which is causing the Divert valve to continuously motor open/close with consequential impact on the CH and cycling hot/cold water when DHW demanded.

I have found 240v is permanently on the CLOSE terminal on the divert valve, when CH is demanded 240v is applied to the OPEN terminal but as power is still on the CLOSE terminal the actuator just continues to run OPEN - CLOSE as power is permanently applied to both sides.

I suspected the PCB so acquired another board (second hand but supposedly from a working boiler !) so either the 2nd PCB features the same problem (unlikely ??? but possible !!) or something else is preventing the CLOSE demand being switched off when CH is demanded.

DHW functions fine no CH demand and CH works fine if I isolate the divert valve actuator in the OPEN position by removing the moles connector.

Any ideas ?