HI there,

So, as part of the EDF free insulation scheme I've just had my loft insulation increased. The original was about 80mm laid between joists and the new stuff is 200mm laid perpendicularly over the joists (see attached photo). I know need to board out the centre section for storage.

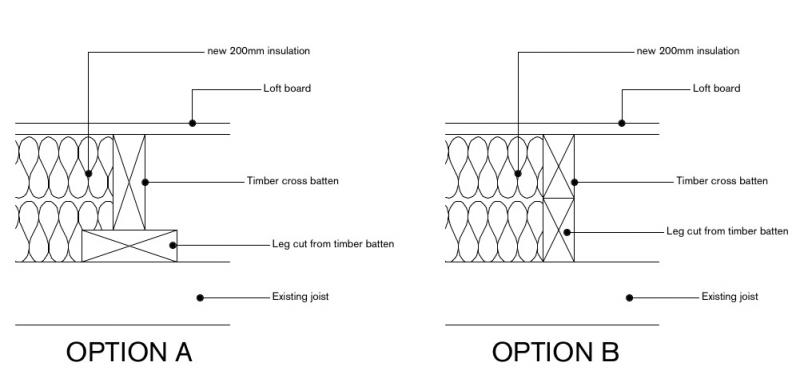

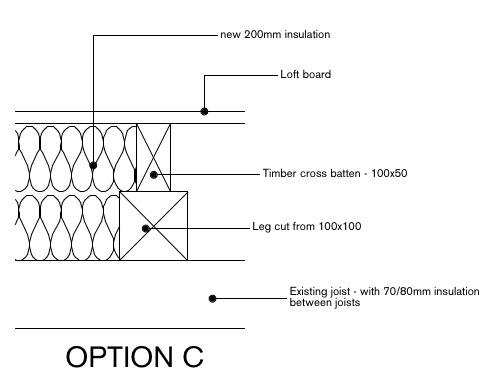

Was originally going to install 7" or 8" x 2" cross battens onto existing joists and affix loft boards to these. Having read another post here I'm thinking that I'll use a smaller section timber (to save weight and cost) and simply cut sections of the timber off to use as legs at each joist (see attached drawing ).

Now have the following queries:

-Which option of attached sketch should I use for the 'legs'?

-Intend to screw the boards into the cross battens but how should I connect A) legs onto joists and B) battens onto legs?

-What height above the joists should I aim for given the 200mm of insulation? Should I clear the whole 200mm or would I get away with compressing it by 20-50mm?

Would really appreciate people's thoughts on this as I hope to do it this weekend.

Thanks in advance

So, as part of the EDF free insulation scheme I've just had my loft insulation increased. The original was about 80mm laid between joists and the new stuff is 200mm laid perpendicularly over the joists (see attached photo). I know need to board out the centre section for storage.

Was originally going to install 7" or 8" x 2" cross battens onto existing joists and affix loft boards to these. Having read another post here I'm thinking that I'll use a smaller section timber (to save weight and cost) and simply cut sections of the timber off to use as legs at each joist (see attached drawing ).

Now have the following queries:

-Which option of attached sketch should I use for the 'legs'?

-Intend to screw the boards into the cross battens but how should I connect A) legs onto joists and B) battens onto legs?

-What height above the joists should I aim for given the 200mm of insulation? Should I clear the whole 200mm or would I get away with compressing it by 20-50mm?

Would really appreciate people's thoughts on this as I hope to do it this weekend.

Thanks in advance