Hi,

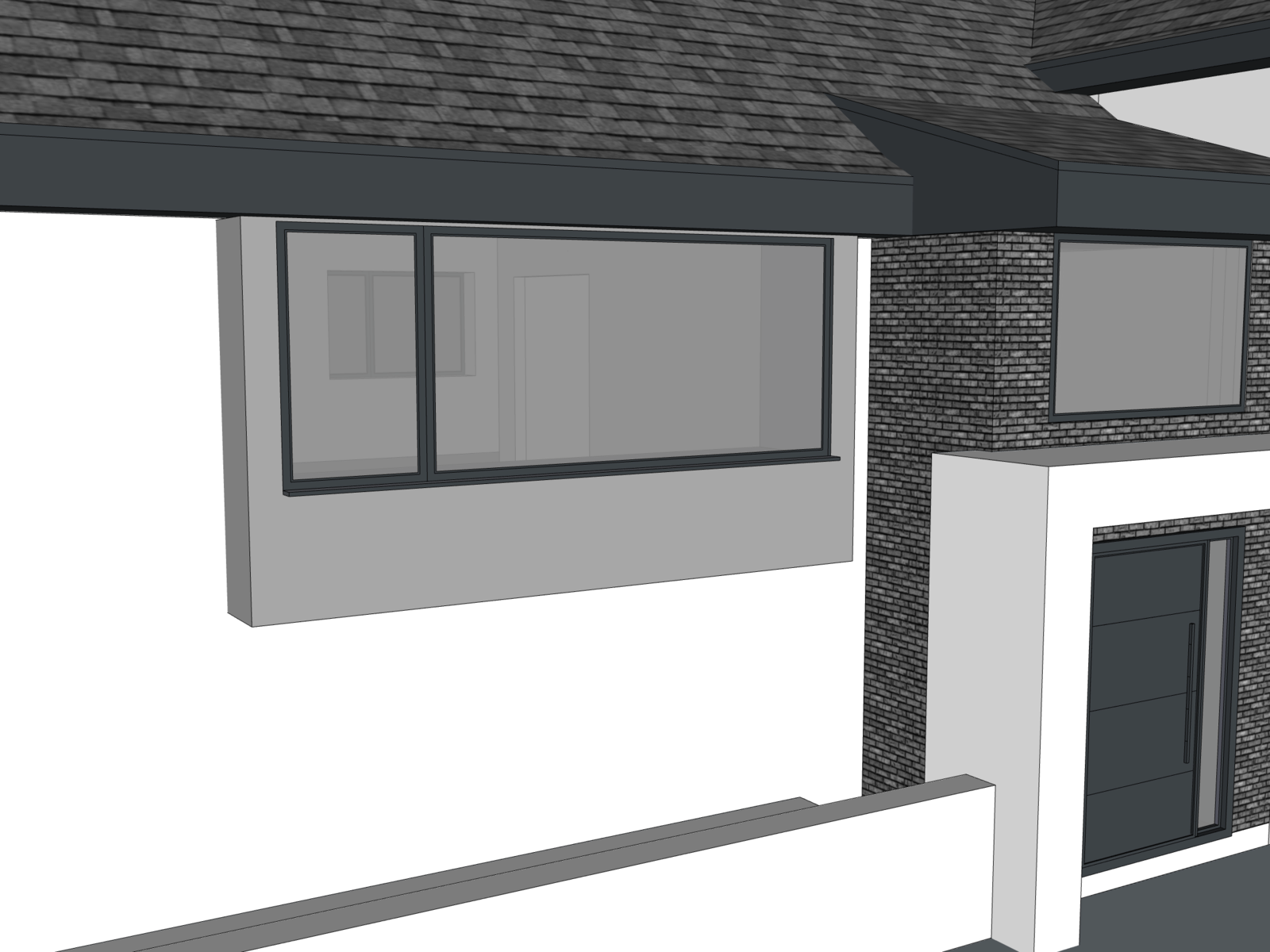

I’d like to replace this window:

With this:

Inside it would look something like this:

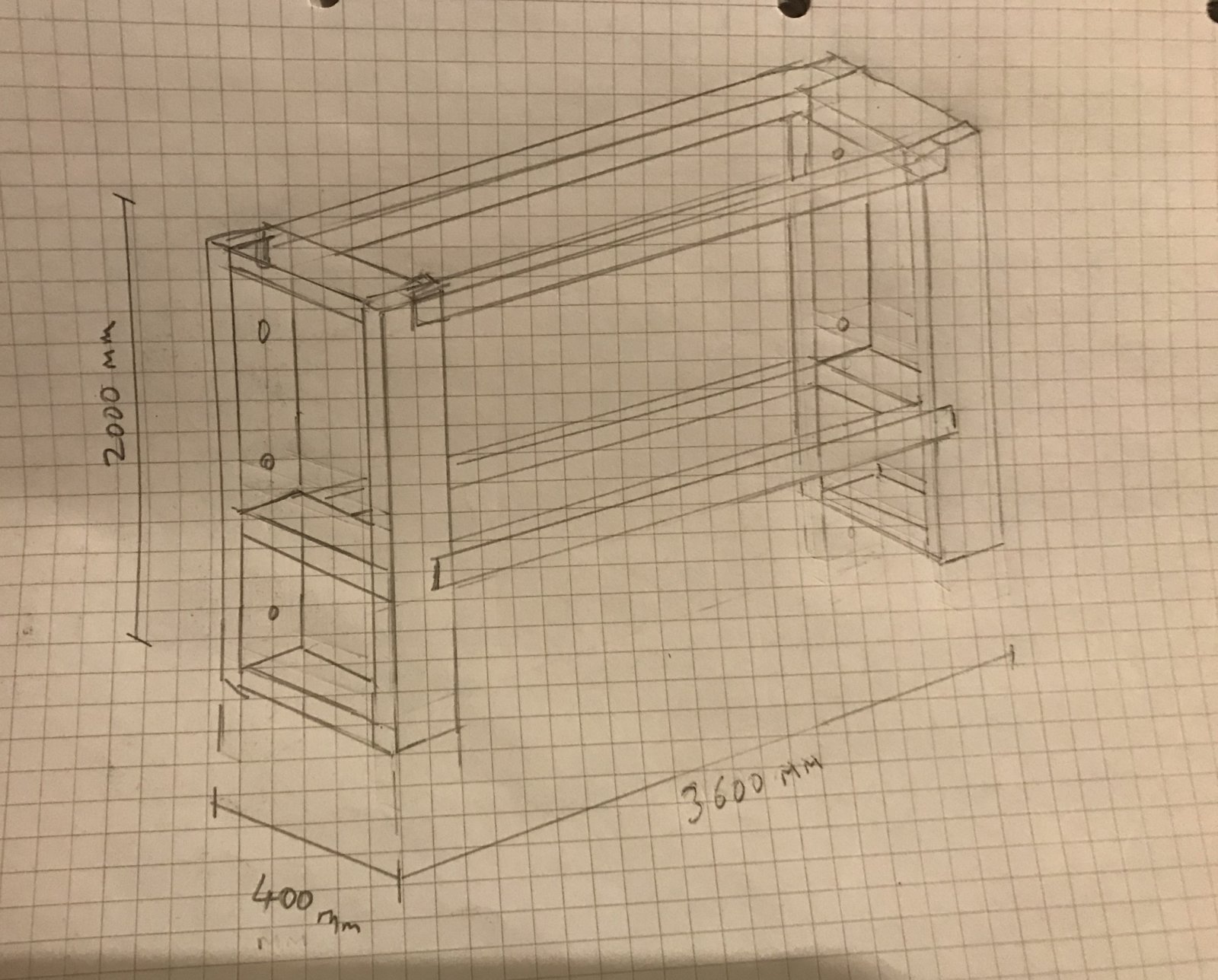

I was wondering what the best way of framing it was.

I was thinking 6 x2 verticals bolted (wall anchors) against the wall either side, 4x2 horizontals something like this:

The existing bay has four supports from the rafters above which I could use. I could add two steel angle brackets below to add to the three wooden ones.

Rockwool or celotex in the gaps, OSB or plywood shell, plywood cill, wrapped in tyvek membrane.

Then to finish ... not sure yet! Aquapanel and rendered or aluminium pressings?

That’s what I was thinking anyway. Any chance any experts can tell me how to do it properly?

Thanks!

ps. The window and frame weighs 142kg!

I’d like to replace this window:

With this:

Inside it would look something like this:

I was wondering what the best way of framing it was.

I was thinking 6 x2 verticals bolted (wall anchors) against the wall either side, 4x2 horizontals something like this:

The existing bay has four supports from the rafters above which I could use. I could add two steel angle brackets below to add to the three wooden ones.

Rockwool or celotex in the gaps, OSB or plywood shell, plywood cill, wrapped in tyvek membrane.

Then to finish ... not sure yet! Aquapanel and rendered or aluminium pressings?

That’s what I was thinking anyway. Any chance any experts can tell me how to do it properly?

Thanks!

ps. The window and frame weighs 142kg!