Bit confused by your comment about 'closing the bypass'. The idea of an automatic bypass is (usually) that it's set so that it ONLY opens automatically when the pressure in the system rises past its setpoint (ie. when everything else (TRVs etc.) is shut). Why do you need to adjust it once set?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building Regs and replacing vented cylinder with Heat Bank

- Thread starter SumoAl

- Start date

croydoncorgi said:Bit confused by your comment about 'closing the bypass'. The idea of an automatic bypass is (usually) that it's set so that it ONLY opens automatically when the pressure in the system rises past its setpoint (ie. when everything else (TRVs etc.) is shut). Why do you need to adjust it once set?

Yep, in this case I was trying to push the full power of the pump through into the areas of the central heating that are not performing very well. Flow through the bypass only stopped (well, sounded like it had stopped) when it was almost totally closed.

Where it is normally set (by the wonderful BG engineer who must know what he was doing) the circulation is mostly through the bypass and little through the radiator even when the radiator lockshield is totally open and the TRV is totally open.

But then I put the bypass back to a more reasonable (for the boiler anyway) setting so that the flow through the boiler wouldn't suffer.

I have another BG engineer coming out tomorrow (under the HomeCare 300 contrat we have) to work out why the boiler keeps cutting out. They are sending a "Senior Engineer" out, whatever one of those is, as it's listed as an unknown fault on their notes. None of the others they have sent have been any use so far. Actually, had a "line manager" in last time as well (there were three of them in the house at the time) who pointed out that the vent and the F&E pipes where too far apart, there's about 4-5 feet between them, but then didn't say anything else other than agree that pouring in a bottle of "chemicals" would be the next step!

It stopped the boiler banging away, but it still cuts out all the time.

I can but hope for the best.

I don't really want to ask him about the flow into the dining room/kitchen as he'll probably just suggest a powerflush (do they still get rewarded for selling those?) and that's going to be very expensive. If I need to go down that route I would rather call a plumber in the village to do it rather than give the work to BG.

Sumo,

I think you are over complicating things here. The lockshields are there to balance individual rads against each other so that they all work effectviely as a system. If they all warm up (assuming a demand for heat) then leave them alone. Fiddling with them can really screw the working of the heating system. Balancing the system is a separate issue to the control system. The (differential?) by-pass is normally set to 2.5, but a higher setting wouldn't harm things. If the system is balanced but you are still having warm-up issues, then perhaps try a larger pump.

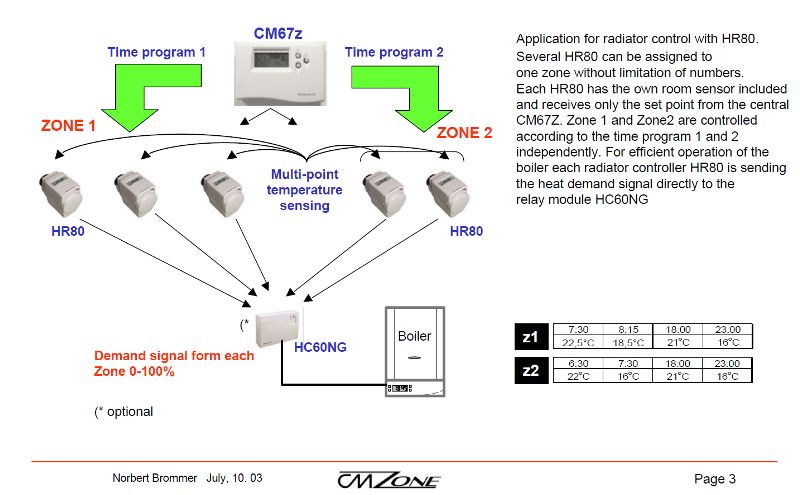

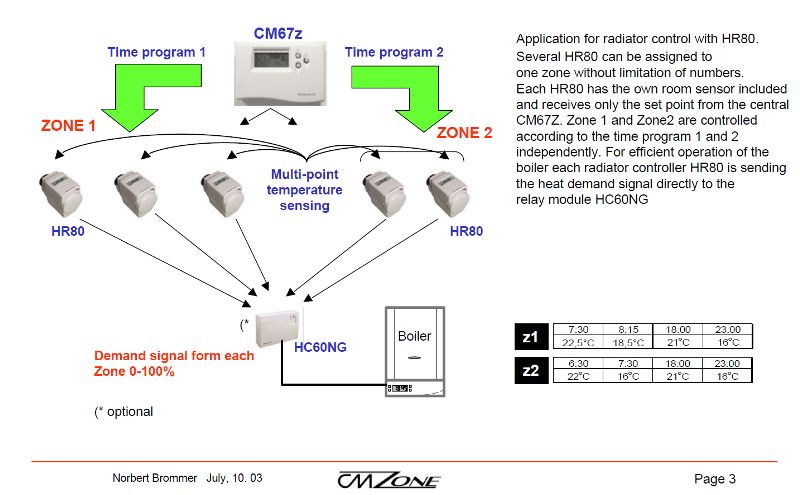

The valve heads measure air temparature and report back to the CM67Z. The CM67z just sends the current set temperature to the HR80; The HR80 sends the current temperature to the HC60NG which uses its percentage algorithmyjiget to operat the zone valve and boiler.

You mentioned a separate timer that has control of the heating system with a +1 button? Turn that to constant - otherwise you will be confusing the CM system.

My personal feelings here is that you have mixed different problems together to create a confusing mess, and that they needs osrting out separately. Was the CMZone system installed for the desire to make the system more efficient? Ro was it because there was an apprent problem and it was seenas a solution? If so - big mistake.

Reset all the CMZone system back to the factory settings. Bond them appropiately and program the CM67z to what you want. Get the system balanced properly and functioning. Ignore the time clock - apart from hot water of course.

DD loves his heat banks etc., and would want everyone to have them - they have their places don't get me wrong, but I feel that you have nothing fundamentally wrong with your system that correct setting up wouldn't fix.

I think you are over complicating things here. The lockshields are there to balance individual rads against each other so that they all work effectviely as a system. If they all warm up (assuming a demand for heat) then leave them alone. Fiddling with them can really screw the working of the heating system. Balancing the system is a separate issue to the control system. The (differential?) by-pass is normally set to 2.5, but a higher setting wouldn't harm things. If the system is balanced but you are still having warm-up issues, then perhaps try a larger pump.

The valve heads measure air temparature and report back to the CM67Z. The CM67z just sends the current set temperature to the HR80; The HR80 sends the current temperature to the HC60NG which uses its percentage algorithmyjiget to operat the zone valve and boiler.

You mentioned a separate timer that has control of the heating system with a +1 button? Turn that to constant - otherwise you will be confusing the CM system.

My personal feelings here is that you have mixed different problems together to create a confusing mess, and that they needs osrting out separately. Was the CMZone system installed for the desire to make the system more efficient? Ro was it because there was an apprent problem and it was seenas a solution? If so - big mistake.

Reset all the CMZone system back to the factory settings. Bond them appropiately and program the CM67z to what you want. Get the system balanced properly and functioning. Ignore the time clock - apart from hot water of course.

DD loves his heat banks etc., and would want everyone to have them - they have their places don't get me wrong, but I feel that you have nothing fundamentally wrong with your system that correct setting up wouldn't fix.

Dan Robinson wrote

Are you sure about that ?. It states on the cm zone MI,s that the

HR 80 is a transceiver and it receives current setpoint value from the remote room unit CM 60Z. In this way, it maintains the time and temperature program set by the user. The HR 80 also sends a load demand signal to the boiler box HC 60NG.

The HR 80 radiator controller can be easily fitted to any conventional radiator valve. Honeywell, Braukmann, MNG, Heimeier, Junkers, and Landis & Gyr Duogyr valves do not require adapters. The HR 80 is adapting itself automatically

The valve heads measure air temparature and report back to the CM67Z

Are you sure about that ?. It states on the cm zone MI,s that the

HR 80 is a transceiver and it receives current setpoint value from the remote room unit CM 60Z. In this way, it maintains the time and temperature program set by the user. The HR 80 also sends a load demand signal to the boiler box HC 60NG.

The HR 80 radiator controller can be easily fitted to any conventional radiator valve. Honeywell, Braukmann, MNG, Heimeier, Junkers, and Landis & Gyr Duogyr valves do not require adapters. The HR 80 is adapting itself automatically

SumoAl wrote

Big mistake and a costly one I would guess for little or no benefit as your postings suggest.

Standard good quality trv,s are more than sufficient on most domestic heating systems using rads as the emitters where zone valves are incorporated IMO.

When I put it in beginning of last year

and it's just not working well at the moment.

Big mistake and a costly one I would guess for little or no benefit as your postings suggest.

Standard good quality trv,s are more than sufficient on most domestic heating systems using rads as the emitters where zone valves are incorporated IMO.

Sorry - misedited it - the missus was trying to get me to sort Skype out with the in-laws on the phone... Not wasy in two languages let alone when you are trying to explain CMZone...

I think you'll find I self corrected myself in the next sentence...

Straight from Honeywell documents

I think you'll find I self corrected myself in the next sentence...

Straight from Honeywell documents

Stepping back and looking at the whole picture again, I'm struck by the mismatch between your boiler and the rest of the setup.

The WB19/24 is already quite old and inefficient. Moreover, it has a requirement for quite a high minimum flow rate and does not (it appears) have much capacity to modulate its own output down. A boiler that makes banging noises is not a happy boiler - it's usually because it's boiling - ie. overheated. Does it / has it ever shown other symptom, such as lockout light on constantly?

An advantage of current model condensing boilers is that they can modulate down their output to a much greater extent so that high bypass flow rates are unnecessary. Seems to me your money would be better spent on a condensing system boiler with an inbuilt modulating pump also, so that the boiler can adjust its output and the system flowrate to match demand.

Taking a ridiculous example: I was working today on a 50Kw boiler called upon in summer to do just hot water heating. OK - admittedly a BIG unvented cylinder but it can still only take a max of about 10Kw. Boiler (and electronic pump) can both modulate down so that boiler only produces 9Kw and flow rate is appropriate to just the cylinder. As it happens, one of the problems I was looking at was in fact pump noise because the pump was set to too high output pressure and was not stepping down enough. Boiler itself was perfectly comfortable (although not in fact condensing much!) at this low output.

The WB19/24 is already quite old and inefficient. Moreover, it has a requirement for quite a high minimum flow rate and does not (it appears) have much capacity to modulate its own output down. A boiler that makes banging noises is not a happy boiler - it's usually because it's boiling - ie. overheated. Does it / has it ever shown other symptom, such as lockout light on constantly?

An advantage of current model condensing boilers is that they can modulate down their output to a much greater extent so that high bypass flow rates are unnecessary. Seems to me your money would be better spent on a condensing system boiler with an inbuilt modulating pump also, so that the boiler can adjust its output and the system flowrate to match demand.

Taking a ridiculous example: I was working today on a 50Kw boiler called upon in summer to do just hot water heating. OK - admittedly a BIG unvented cylinder but it can still only take a max of about 10Kw. Boiler (and electronic pump) can both modulate down so that boiler only produces 9Kw and flow rate is appropriate to just the cylinder. As it happens, one of the problems I was looking at was in fact pump noise because the pump was set to too high output pressure and was not stepping down enough. Boiler itself was perfectly comfortable (although not in fact condensing much!) at this low output.

D

Doctor Drivel

SumoAl said:OK, the situation is this, I appear to be caught up in some internal politics on this site with some DD making up posts to justify heat banks. Never mind.

I do not make up posts as some idiots have alleged.

As you may gleen, many here just don't understand heat banks.

D

Doctor Drivel

Dan_Robinson said:But with the control system Sumo has there is no need for the boiler to short cycle. There is simply no point installing a heat bank for the sake of it.

the boiler will short cycle if demans is more than the lowest boiler output. this

D

Doctor Drivel

croydoncorgi said:Stepping back and looking at the whole picture again, I'm struck by the mismatch between your boiler and the rest of the setup.

The WB19/24 is already quite old and inefficient. Moreover, it has a requirement for quite a high minimum flow rate and does not (it appears) have much capacity to modulate its own output down.

so will short cycle

A boiler that makes banging noises is not a happy boiler - it's usually because it's boiling - ie. overheated.

So coupling it up to a heat bank (buffer) will enhace it performance as it will be running on full flow through the boiler at all times when firing.

Taking a ridiculous example: I was working today on a 50Kw boiler called upon in summer to do just hot water heating. OK - admittedly a BIG unvented cylinder but it can still only take a max of about 10Kw.

It needs a bronze pump and a plate heat exchanger, and it will condesne as well.

It needs a bronze pump and a plate heat exchanger, and it will condesne as well.

To achieve THAT would require secondary TAPPINGS and the Megaflo ain't got any!!!

Don't blame me-I didn't fit it.

(As it is, the secondary Return from the bronze-body pump that IS fitted goes into the cold feed to the cylinder, with inconvenient consequences. Best I could do was fit a pipestat to keep pump operating time to minimum.)

Or do you mean 'Turn the Unvented Cylinder into a heatstore'? Given the scale of the DHW pipework on this system and the existence of a secondary circulation already, I think that would be a spectacularly bad idea and definitely overkill!

Thank you all for your replies, this thread does appear to have got confusing, I pity anybody trying to read through it now!

The heat bank idea is now on hold, maybe for a long time. I still think it would work very well and that a CH buffer tank would give me a lot of benefit coupled with an Grundfos Alpha Pro (I do like my digital readouts it would appear) but lets get other things sorted first!

The boiler isn't happy at all, BG put some Fernox boiler silencer stuff (sorry, didn't see bottle for number) which stopped it banging away but it is still cutting out (flashing the warning light twice every two seconds or so), and cuts out on average once every other day - so quite often. All it's currently being asked to do is to heat up the BS standard (so quite crappy [hey - it's changing my words]) vented hot water tank and it's failing to do that.

So the boiler needs sorting, so far BG have replaced the PCB, gas valve, air sensor and burner (at least that lot, lost track). Only after that lot did anybody poke their head up and look at the pipework in the attic, and that was mostly to pour the bottle into the header tank. BG have been back in today and are going to put in another new PCB on Tuesday.

In addition reading through this thread again it appears there maybe a major balancing issue, actually that may be the major issue I have with the CMZ system. Having to shut down the locksheilds on seven radiators to bairly a crack open to try and get flow into an eight radiator won't be helping one bit. Wonder what would happen if I sacrifice that radiator (leaving the lockshield open wide) and balance the system just based on the others, that would mean that they would be much more open. Then the dining room would eventually heat up when all the others started to shut down. Worth a go?

The CMZone system was put in to allow different set points in different rooms at different times of the day. Taking into account three different sleeping patterns was the primary aim, efficiency was secondary, and it wasn't put in to solve any system problems. Most of the time it's achieving it's objective and I'm happy with that. Yes, maybe a bit over the top but it's spent now.

CroydonCorgi, I understand your point and it's very tempting just to say goodbye to the current setup and put in a modulating condensing system boiler. But as nearly every part of the boiler is new it a bit of a waste.

The heat bank idea is now on hold, maybe for a long time. I still think it would work very well and that a CH buffer tank would give me a lot of benefit coupled with an Grundfos Alpha Pro (I do like my digital readouts it would appear) but lets get other things sorted first!

The boiler isn't happy at all, BG put some Fernox boiler silencer stuff (sorry, didn't see bottle for number) which stopped it banging away but it is still cutting out (flashing the warning light twice every two seconds or so), and cuts out on average once every other day - so quite often. All it's currently being asked to do is to heat up the BS standard (so quite crappy [hey - it's changing my words]) vented hot water tank and it's failing to do that.

So the boiler needs sorting, so far BG have replaced the PCB, gas valve, air sensor and burner (at least that lot, lost track). Only after that lot did anybody poke their head up and look at the pipework in the attic, and that was mostly to pour the bottle into the header tank. BG have been back in today and are going to put in another new PCB on Tuesday.

In addition reading through this thread again it appears there maybe a major balancing issue, actually that may be the major issue I have with the CMZ system. Having to shut down the locksheilds on seven radiators to bairly a crack open to try and get flow into an eight radiator won't be helping one bit. Wonder what would happen if I sacrifice that radiator (leaving the lockshield open wide) and balance the system just based on the others, that would mean that they would be much more open. Then the dining room would eventually heat up when all the others started to shut down. Worth a go?

The CMZone system was put in to allow different set points in different rooms at different times of the day. Taking into account three different sleeping patterns was the primary aim, efficiency was secondary, and it wasn't put in to solve any system problems. Most of the time it's achieving it's objective and I'm happy with that. Yes, maybe a bit over the top but it's spent now.

CroydonCorgi, I understand your point and it's very tempting just to say goodbye to the current setup and put in a modulating condensing system boiler. But as nearly every part of the boiler is new it a bit of a waste.

Sorry to point this out, and never mind about BG's diagnostic skills and repair techniques, but based on your latest remark about lockouts and flashing warning lights, my strong suspicion is that ALL that is (and was?) wrong with the boiler is flow below specified minimum. BG can change the rest of it too, if they want, but IF that's the problem and it's not resolved, the other symptoms won't go away!

croydoncorgi said:Sorry to point this out, and never mind about BG's diagnostic skills and repair techniques, but based on your latest remark about lockouts and flashing warning lights, my strong suspicion is that ALL that is (and was?) wrong with the boiler is flow below specified minimum. BG can change the rest of it too, if they want, but IF that's the problem and it's not resolved, the other symptoms won't go away!

[as an aside]

Do you think that the four feet or so between the vent pipe and the F&E pipe is helping matters? Everything I've seen says 6" max. Don't know what the implications of this are.

[now back on track]

I currently have a Grundfos 15-50 on III servicing the indirect coil of the cylinder. Could it be that the 30' or so of 22mm pipework going to/from the boiler (so 60' in total) is reducing the head so much that the flow isn't up to scratch even when it's just being asked to push through the indirect coil?

I happen to have a 15-60 new boxed in the garage (was intended for something else - actually for a marine aquarium!) would removing the 15-50 and putting the 15-60 in help at all?

Should this not be something a competent heating engineer find easily enough? Maybe I should call one of those rather than BG.

Separating Vent and Cold Feed CAN mean that the pressures where each connect to the rest of the system are different. Then you can get problems with water running out of the vent pipe when the pump starts up / all the time it's running OR air drawn down the vent pipe. Both lead to aeration of the system water and corrosion, etc. problems.

A Grundfos CI body 15/60 would be about as much use as a Chocolate Teapot pumping salt water! I wouldn't even ask the bronze-body equivalent to do that job. I reckon the iron one would run its bearing in about a week, the bronze one might last a couple of months!

Since you might well be under-piped over that long run (including a few bends, it sounds inevitable) and since you've already got the pump and since changing it should take 10 minutes, why not see if it makes a difference.....

Edit: since you can, try the other pump anyway. But on further thought, I don't think there'd be much resistance (less than 1m head) in a long run of 22mm to (say) 0.2 litre/sec, which is all you'd need to deliver 10Kw to a cylinder on a temperature drop of (say) 80 C degrees down to 69. ....

A Grundfos CI body 15/60 would be about as much use as a Chocolate Teapot pumping salt water! I wouldn't even ask the bronze-body equivalent to do that job. I reckon the iron one would run its bearing in about a week, the bronze one might last a couple of months!

Since you might well be under-piped over that long run (including a few bends, it sounds inevitable) and since you've already got the pump and since changing it should take 10 minutes, why not see if it makes a difference.....

Edit: since you can, try the other pump anyway. But on further thought, I don't think there'd be much resistance (less than 1m head) in a long run of 22mm to (say) 0.2 litre/sec, which is all you'd need to deliver 10Kw to a cylinder on a temperature drop of (say) 80 C degrees down to 69. ....

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

G

- Replies

- 1

- Views

- 1K

- Replies

- 1

- Views

- 1K

- Replies

- 9

- Views

- 3K