hi all, I've recently fitted a new central heating system and all has been great until the latest two radiators, they don't appear to heat up like the others. I've attempted to balance the system but doesn't appear to help much. I'm wondering if maybe my pipe design could be causing the issues, as I'm not a heating engineer and have taken this on myself. I'm just looking for some advice and thoughts on the system I've installed and if the design could be the cause, or maybe what else could be the cause?

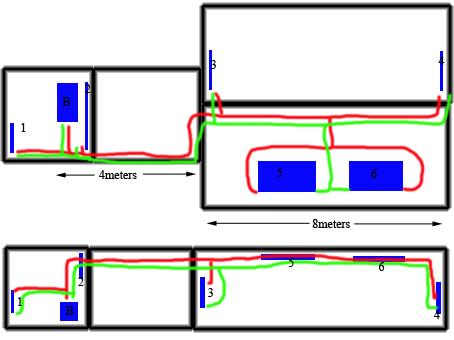

See the attached picture for a overview of the design in the building, (red flow, green rtn, blue=boiler and rads, black=walls). Radiators 5 & 6 that are being problematic. all the pipework is 15mm, and is combination of plastic and copper. There are two manual air release valves above the main branch for rads 5&6.

The boiler is brand new Valiant 838.

The problem radiators used are http://www.ebay.co.uk/itm/400485619...eName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649 the others are a mix of standard b&q dbl steels, towel rads and a upright designer similar to the ones in the link above but its a single.

All rads have TRV's and as mentioned above I've tried balancing to the point that all rads other then 5&6 now have only a quarter turn on the LockShield. All rads are set to level 5 on the TRV side.

It appears now that rad 6 heats up at the start of the heating system coming on, but then cools over time, so doesn't maintain temperature.

My next stage of investigation is to remove the TRV's off 5&6 to eliminate them, although on bleeding they do fill up fine.

cheers for any assistance. and let me know if you want more info.[/url]

See the attached picture for a overview of the design in the building, (red flow, green rtn, blue=boiler and rads, black=walls). Radiators 5 & 6 that are being problematic. all the pipework is 15mm, and is combination of plastic and copper. There are two manual air release valves above the main branch for rads 5&6.

The boiler is brand new Valiant 838.

The problem radiators used are http://www.ebay.co.uk/itm/400485619...eName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649 the others are a mix of standard b&q dbl steels, towel rads and a upright designer similar to the ones in the link above but its a single.

All rads have TRV's and as mentioned above I've tried balancing to the point that all rads other then 5&6 now have only a quarter turn on the LockShield. All rads are set to level 5 on the TRV side.

It appears now that rad 6 heats up at the start of the heating system coming on, but then cools over time, so doesn't maintain temperature.

My next stage of investigation is to remove the TRV's off 5&6 to eliminate them, although on bleeding they do fill up fine.

cheers for any assistance. and let me know if you want more info.[/url]