Hi all,

I've just moved into a 1930's semi with no central heating, just storage heaters and an old immersion heater, so i'm planning on ripping it all out and putting in a new Combi system - the only thing is i've only ever fixed/added onto systems before not run from scratch.

(Obviously getting someone fully qualified to handle the actual boiler work(!) but there's so much work that needs doing that i need to cut some costs somewhere...!)

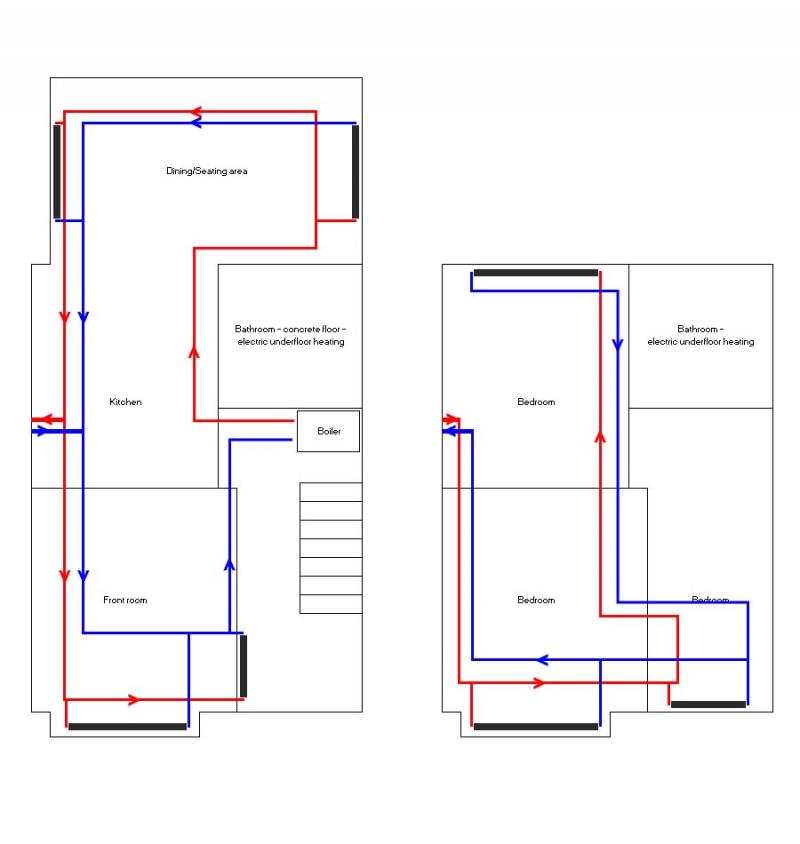

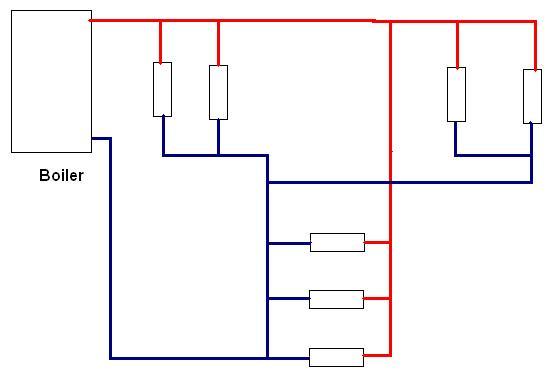

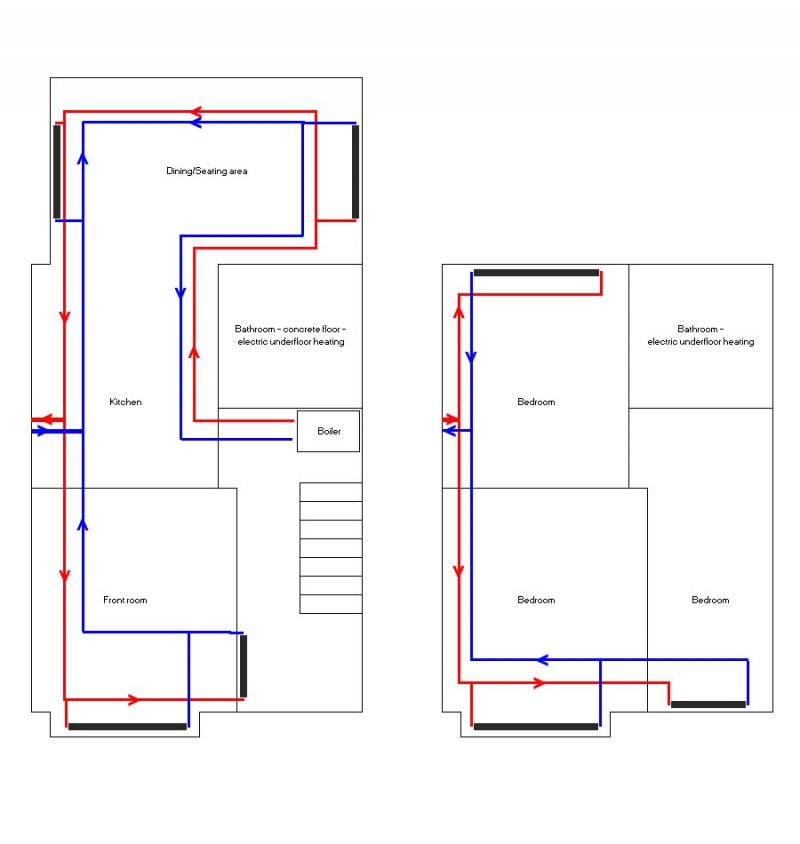

i've drawn a layout - does this look correct or have i made too many mistakes to know where to start??

I must admit i wasn't sure on the return, if it need to come back the first rad, rather than the hall rad?

Do the main rings need to be all in 22mm with just the tees off being in 15mm?

The dining section at the back hasn't been built yet, and the builder has costed for a screeded floor - can the Hep2o barrier pipe be laid into that? What about the joints or do i need another solution altogether?

Sorry, rookie questions here i know!

Any help massively appreciated!!

Cheers,

Kev

I've just moved into a 1930's semi with no central heating, just storage heaters and an old immersion heater, so i'm planning on ripping it all out and putting in a new Combi system - the only thing is i've only ever fixed/added onto systems before not run from scratch.

(Obviously getting someone fully qualified to handle the actual boiler work(!) but there's so much work that needs doing that i need to cut some costs somewhere...!)

i've drawn a layout - does this look correct or have i made too many mistakes to know where to start??

I must admit i wasn't sure on the return, if it need to come back the first rad, rather than the hall rad?

Do the main rings need to be all in 22mm with just the tees off being in 15mm?

The dining section at the back hasn't been built yet, and the builder has costed for a screeded floor - can the Hep2o barrier pipe be laid into that? What about the joints or do i need another solution altogether?

Sorry, rookie questions here i know!

Any help massively appreciated!!

Cheers,

Kev