You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Changing a radiator tail - Drain down or not?

- Thread starter SproutsDad

- Start date

Yes to both. Will look neater as well.So 8mm clipped to skirting board itself .........

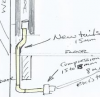

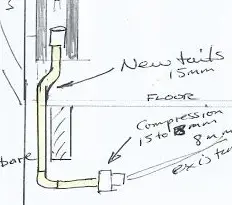

I was trying to make it more robust by having 15mm instead of 8mm above floor, the only hiccup was this dog-leg tail bend in 15mm.

Sounds like you think it is better to get back to 8mm for the whole run but routed snugger and less exposed.

>> Is that instead of mixing 15mm above floor and 8mm below?

>> Would that be your favoured option from where I am now?

If you are concerned might get hit by Hoover, there are of course other makes, then small bit of plastic capping. Painted to match skirting job done about as neat and unobtrusive as you will ever get.

Thanks I do appreciate your input and view on this.

However, I feel I am going round in circles. I started asking how to run the 15mm in a neater way, now that the rad is positioned closer to the wall, advice was yes, to go that route.

My question was .....

and now

Now the advice is to definitely stick with microbore. That takes me back to where I started out.

About half of our house still has the 35 year old original installation 8mm microbore. While we were doubling the house in size 15 years ago I should have pushed the plumber then to replace everything, but he didn't want to! Hindsight and all that. Microbore has caused so many problems, leaks, damage and this seemed the ideal opportunity to use the more robust 15mm above floor level on a new radiator. The only issue seemed to be in bending it.

And I am convinced that today's pipe is a much thinner section, bending with the spring didn't make it kink like this a few years ago.

Q? >> I think I can borrow a bender, what if I bend prettier tails with that and stick to my proposed route of 15mm?

I really don't want to go back to microbore above floor unless there is a compelling case for it.

>> Opinions please.

Thanks

However, I feel I am going round in circles. I started asking how to run the 15mm in a neater way, now that the rad is positioned closer to the wall, advice was yes, to go that route.

My question was .....

Or should this be a gentle bend with no elbow?

>>> Also. Would you be doing this at all based on what I have described, just to pull a rad and its tails in closer to the wall?

>>> Or would you have left it? See Now and Proposed in sketch in earlier post << Your opinion, just for my curiosity please!

Definitely worth doing

and now

and .....If you have 8mm main pipe to radiator why not extend this in 8mm bring it up behind joist

I would also take 8 mm to the rad.

, perhaps using larger copper tube on the outside.

Now the advice is to definitely stick with microbore. That takes me back to where I started out.

About half of our house still has the 35 year old original installation 8mm microbore. While we were doubling the house in size 15 years ago I should have pushed the plumber then to replace everything, but he didn't want to! Hindsight and all that. Microbore has caused so many problems, leaks, damage and this seemed the ideal opportunity to use the more robust 15mm above floor level on a new radiator. The only issue seemed to be in bending it.

And I am convinced that today's pipe is a much thinner section, bending with the spring didn't make it kink like this a few years ago.

Q? >> I think I can borrow a bender, what if I bend prettier tails with that and stick to my proposed route of 15mm?

I really don't want to go back to microbore above floor unless there is a compelling case for it.

>> Opinions please.

Thanks

Attachments

I always used to do it over my knee but then hurt myself going too hard at it. I'll cushion it with a folded towel or similar.

Thanks a lot gas112.

Q? >> copper pipe section is thinner these days though isn't it?!

All the best

Thanks a lot gas112.

Q? >> copper pipe section is thinner these days though isn't it?!

All the best

You know, I think you're right. All this effort and pondering trying to use a gentle bend for more efficient flow when my gut feeling as a DIYer would be to go for elbows above floor and where it gets tight below to use compression's. But that seems to get frowned on by the professionals, depending on who you speak to?Why not just solder a street elbow offset sectio

However, in this instance it might be the best solution, or what does anyone else say? I can beg, borrow or buy a pipe bender or do my knee in bending it when end feed elbows should do the job??

I could make the dog-leg offset from 2 street elbows and use a end feed elbow beneath the floor, if I can drop it all in around the joist, then connect up to the existing 15 to 8mm compression below the floor.

Job done, or?

DIYnot Local

Staff member

If you need to find a tradesperson to get your job done, please try our local search below, or if you are doing it yourself you can find suppliers local to you.

Select the supplier or trade you require, enter your location to begin your search.

Please select a service and enter a location to continue...

Are you a trade or supplier? You can create your listing free at DIYnot Local

Similar threads

- Replies

- 4

- Views

- 4K

- Replies

- 1

- Views

- 1K

- Replies

- 4

- Views

- 5K

B