We're working on speccing up a GluLam beam as previously discussed, as a 6.5m support beam under a solid wall holding up a roof. Our engineer is being a bit slow to specify size or the load requirements so I was looking at LilleHeden's span tables in the interim to try and get a rough idea on size and cost and weight - the taller the beam is the more work we have to do to get it in properly and getting a head-start on that would be good.

http://www.lilleheden.co.uk/Files/Files/Spændviddetabel/Lilleheden_SpanTable_2019_UK_web.pdf

I was wondering, just how do steels compare to Glulam in terms of strength for this sort of application, in ballpark terms? Of course I've seen reasonable spans when people knock out a ground-floor wall, and seemingly quite small RSJs can support the entire weight of a house over quite large spans.

Not the prettiest option but seemingly more affordable as well? If it saved a few inches head-room that might be worth it.

Then I wondered, are there other options? Plastic, weird hi-tech materials you'd see on Grand Designs, etc?

By the way, what exactly am I looking to get from a structural engineer here? Some specific numbers about deflection limits and so on, or should he actually tell me the size and type of the beam explicitly?

Thanks.

PS: for those following this whole project, the cabin arrived yesterday (the guy had to drive through a flood on his Moffet!) and the SE has approved the design subject to deciding on the beam.

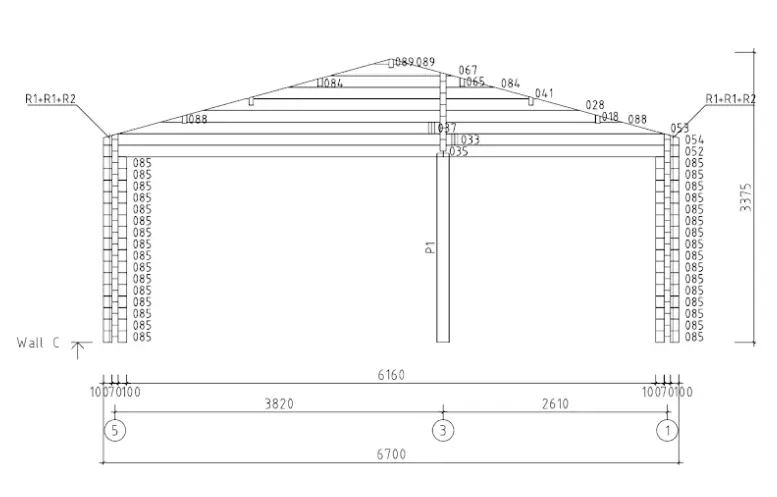

This original design:

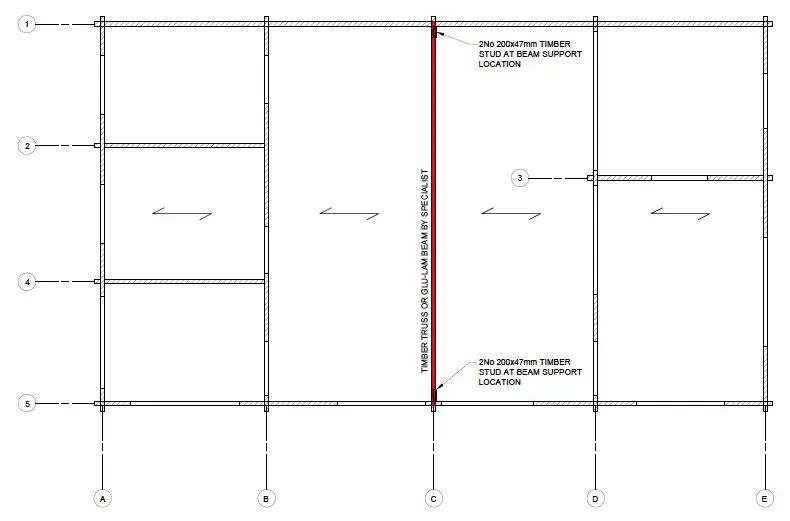

Has us removing post P1and adding the beam, with additional 'cripple beams' supporting each end:

http://www.lilleheden.co.uk/Files/Files/Spændviddetabel/Lilleheden_SpanTable_2019_UK_web.pdf

I was wondering, just how do steels compare to Glulam in terms of strength for this sort of application, in ballpark terms? Of course I've seen reasonable spans when people knock out a ground-floor wall, and seemingly quite small RSJs can support the entire weight of a house over quite large spans.

Not the prettiest option but seemingly more affordable as well? If it saved a few inches head-room that might be worth it.

Then I wondered, are there other options? Plastic, weird hi-tech materials you'd see on Grand Designs, etc?

By the way, what exactly am I looking to get from a structural engineer here? Some specific numbers about deflection limits and so on, or should he actually tell me the size and type of the beam explicitly?

Thanks.

PS: for those following this whole project, the cabin arrived yesterday (the guy had to drive through a flood on his Moffet!) and the SE has approved the design subject to deciding on the beam.

This original design:

Has us removing post P1and adding the beam, with additional 'cripple beams' supporting each end: