- Joined

- 15 May 2017

- Messages

- 14

- Reaction score

- 1

- Country

Hi,

I have a washing machine that bounces around. I've tried many ways to remove the bounce from the floor, but failed. I've given up on damping, supporting the floor, cross members for the joists, sistering the joists.

I want to build a concrete platform for it to sit on.

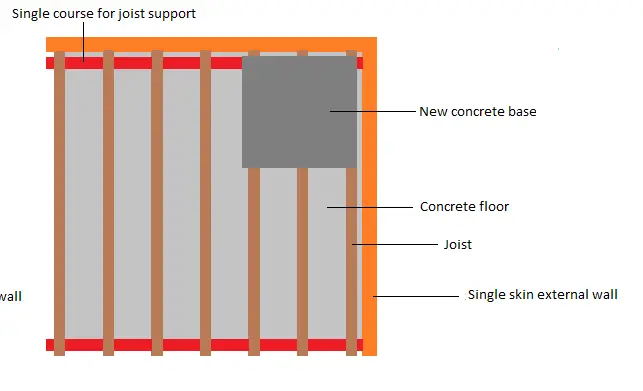

The room is an single skin brick extension. With a concrete base, wooden joists are supported by a single course of bricks on one end and span the full width of the room to sit on top of another single course of bricks. Chipboard is screwed to the joists as floorboard.

If I were to make some kind of base in the corner for the washer to sit on (see diagram), can I just pour concrete in a form and make it level with the top of where the chipboard is now?

1.

What mix would I have to use? The depth of the pad will be about 225mm.

2.

I plan on leaving a small - say 50mm gap between the base and the two walls so not to interfere with the damp course. Is that sensible?

3.

I presume I can pour straight on to the concrete floor?

4.

Should I pour the concrete so that it is top-of-floorboard level, or leave enough to add chipboard as floorboard?

Any help or advice would be appreciated.

Thanks,

Dave.

I have a washing machine that bounces around. I've tried many ways to remove the bounce from the floor, but failed. I've given up on damping, supporting the floor, cross members for the joists, sistering the joists.

I want to build a concrete platform for it to sit on.

The room is an single skin brick extension. With a concrete base, wooden joists are supported by a single course of bricks on one end and span the full width of the room to sit on top of another single course of bricks. Chipboard is screwed to the joists as floorboard.

If I were to make some kind of base in the corner for the washer to sit on (see diagram), can I just pour concrete in a form and make it level with the top of where the chipboard is now?

1.

What mix would I have to use? The depth of the pad will be about 225mm.

2.

I plan on leaving a small - say 50mm gap between the base and the two walls so not to interfere with the damp course. Is that sensible?

3.

I presume I can pour straight on to the concrete floor?

4.

Should I pour the concrete so that it is top-of-floorboard level, or leave enough to add chipboard as floorboard?

Any help or advice would be appreciated.

Thanks,

Dave.