I have two questions but because they are both questions about earthing I thought I would only post once.

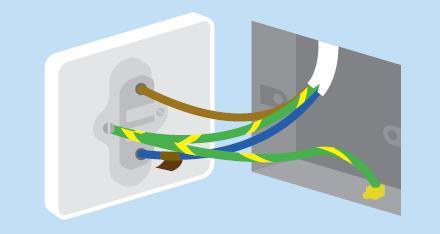

1) I replaced a broken plastic (face plate) shaver socket with a metalic one . I disconnected the old socket and wired the new one the same way. The unit works fine but I wanted to check that I have earthed correctly (see photo). The earth cable coming from the top and the bottom are clamped together into the unit. Is this correct or should both cables be conected to the same connector on the mounting box and a third yellow and green cable go to the connector on the unit?

2) I replaced a switch with a remote control dimmer switch (Varilight) with metal plate behind the plastic. I wired in the same way but I have not got the unit earthed. Like with the shaver socket there is a earth (yellow and green) cable coming from above and below and they are both connected to the metallic mounting box. Should a third cable be connected from this to the switch?

In respect of 1) and 2) alternatively should I just connect to the existing earth cables as per the following diagram and not try to connect the metallic mounting box as well? This is essentially what I have done with the shaver unit.

Apologies in advance for what may prove to be some very stupid questions but I would rather ask than get electrocuted! BTW the property is a 3 year old conversion from offices to flats and must have been re-wired then.

1) I replaced a broken plastic (face plate) shaver socket with a metalic one . I disconnected the old socket and wired the new one the same way. The unit works fine but I wanted to check that I have earthed correctly (see photo). The earth cable coming from the top and the bottom are clamped together into the unit. Is this correct or should both cables be conected to the same connector on the mounting box and a third yellow and green cable go to the connector on the unit?

2) I replaced a switch with a remote control dimmer switch (Varilight) with metal plate behind the plastic. I wired in the same way but I have not got the unit earthed. Like with the shaver socket there is a earth (yellow and green) cable coming from above and below and they are both connected to the metallic mounting box. Should a third cable be connected from this to the switch?

In respect of 1) and 2) alternatively should I just connect to the existing earth cables as per the following diagram and not try to connect the metallic mounting box as well? This is essentially what I have done with the shaver unit.

Apologies in advance for what may prove to be some very stupid questions but I would rather ask than get electrocuted! BTW the property is a 3 year old conversion from offices to flats and must have been re-wired then.