The plumber has temporarily wired up my central heating system to give me hot water and heating. He has wired an S-Plan system as requested but i have noticed he hasn't ran the hot water via the cylinder thermostat so at the moment the boiler heats the water I the cylinder when the programmer tells it to but doesn't stop when it hits the set temp. I have set the programmer to heat water for 1hr in the morning and evening for the time being but i want to run via the stat to prevent potential for overheating and for it to be connected correctly.

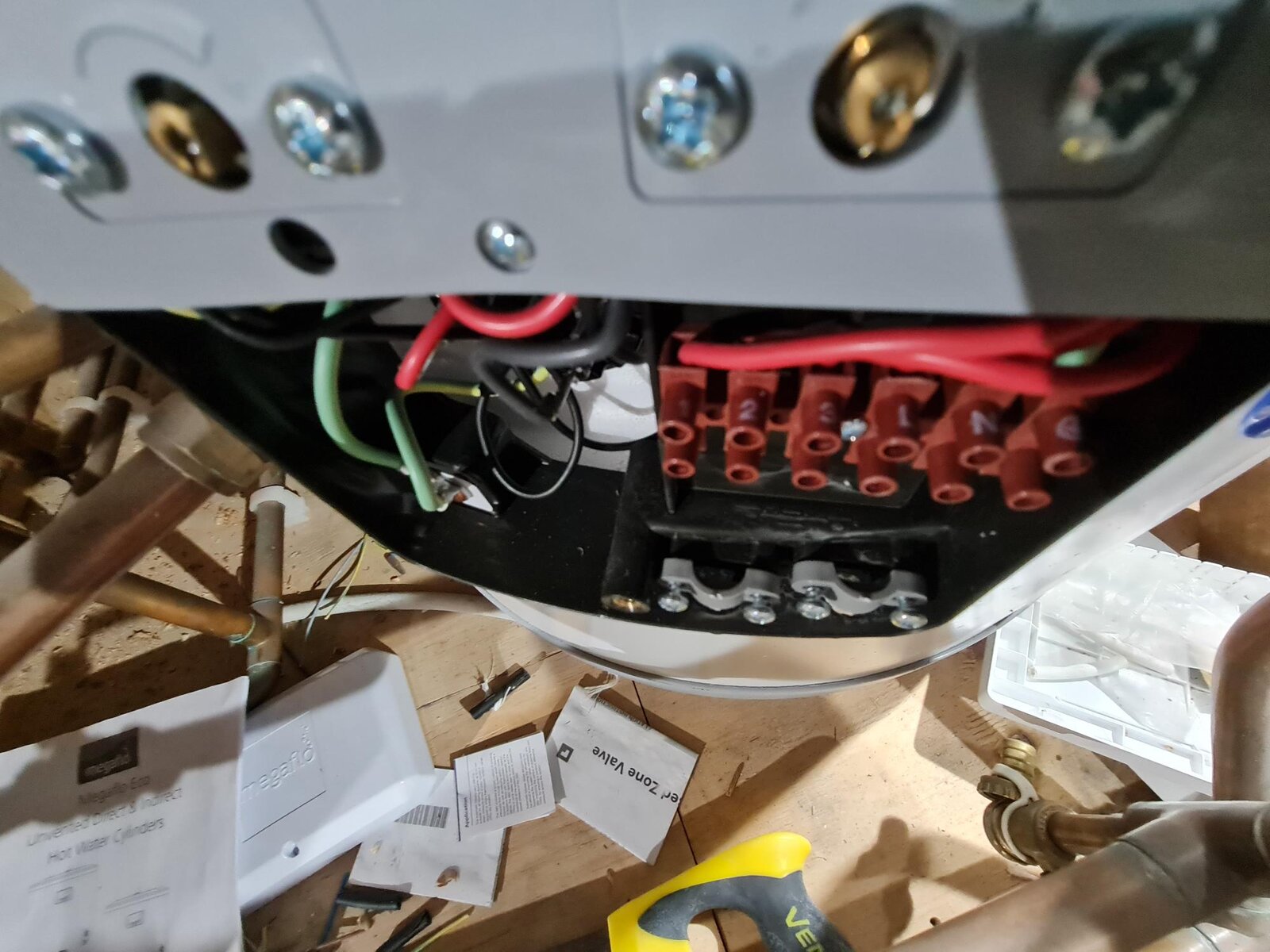

The cylinder has 6 electrical terminals. The 3 on the right are L/N/E. I assume I connect the emersion heater supply here so that if the boiler ever goes down i can flick the water heater switch and heat via the immersion? Is this correct?

On the left there are 3 more terminals labelled 1/2/3. I assume the 2 port valve signal cable goes into one of these and then a cable out back to the control box essentially breaking the heat water command to loop in the cylinder thermostat. Which terminal (1/2/3) is for signal in and which for signal out?

Many thanks in advance

The cylinder has 6 electrical terminals. The 3 on the right are L/N/E. I assume I connect the emersion heater supply here so that if the boiler ever goes down i can flick the water heater switch and heat via the immersion? Is this correct?

On the left there are 3 more terminals labelled 1/2/3. I assume the 2 port valve signal cable goes into one of these and then a cable out back to the control box essentially breaking the heat water command to loop in the cylinder thermostat. Which terminal (1/2/3) is for signal in and which for signal out?

Many thanks in advance