Hi,

I realise there must be a post regarding decking frame planning every other week on here but I am hoping you could indulge me before I go insane.

I have been planning a 8.2m x 4m decking project for what feels like a lifetime and I am so worried I am over engieneering things I thought I would post here.

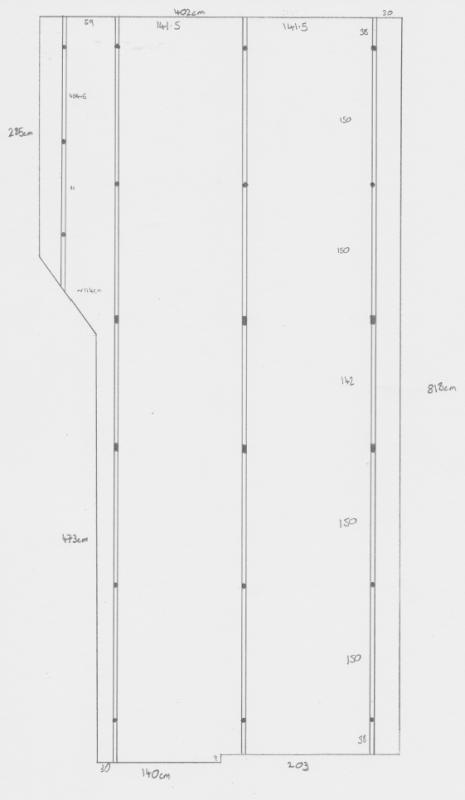

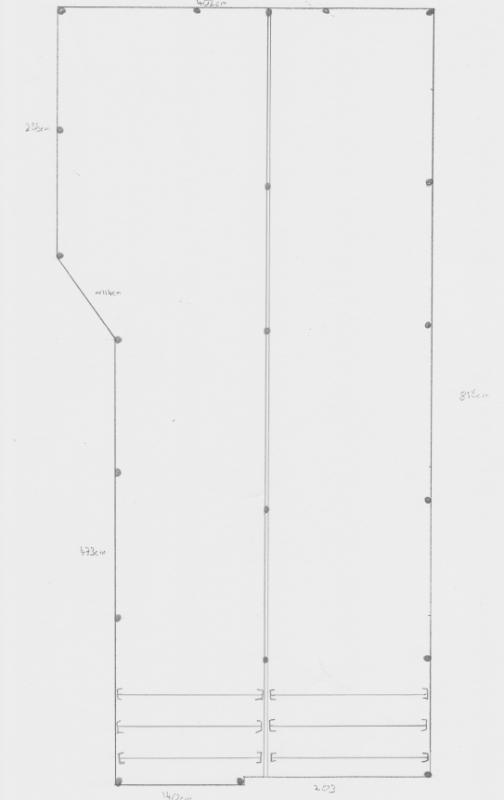

The deck area is rectangular-ish and is a raised deck (but only slightly) which extends out 8m from the back of the house and 4m in width. Here is an image:

Essentially I have a number of 4x4 posts at 1.5m intervals.

Running vertically (as looking at the plan) I have a 4 rows of 2x6 pairs which are bolted to the posts

Now my plan was to then use these beams as bearers and have the 4x2 joist framework sitting on top of these 2x6 support beams. Then obviously have the deck boards running vertically from the back of the house and out.

Is this over-engineered?? I desperately need to know.

Having looked at about a thousand web sites the closest I have come to making this more simple is to simply attach cut-down joists at 400mm centres 'in between' the 2x6 beams. Does that make sense? In other words the joist would be attached (screws or hangers) by butting up to the 2x6 beams. This would mean that instead of having 4m joists running on top of the beams and horizontal to the house I would have roughly 2, 2 metre joists slotted between the beams - running horizontal to the house.

The only thing I am pretty much fixed on is that I will be using posts to support everything. It's the framework that is really confusing me.

I know having a 3 tier system (bearers, joists and decking) is the most rigid method of doing this but is it overkill?

BTW- The bearers would only be hovering 2 inches off the floor.

I really hope someone can help. Thanks for reading.

I realise there must be a post regarding decking frame planning every other week on here but I am hoping you could indulge me before I go insane.

I have been planning a 8.2m x 4m decking project for what feels like a lifetime and I am so worried I am over engieneering things I thought I would post here.

The deck area is rectangular-ish and is a raised deck (but only slightly) which extends out 8m from the back of the house and 4m in width. Here is an image:

Essentially I have a number of 4x4 posts at 1.5m intervals.

Running vertically (as looking at the plan) I have a 4 rows of 2x6 pairs which are bolted to the posts

Now my plan was to then use these beams as bearers and have the 4x2 joist framework sitting on top of these 2x6 support beams. Then obviously have the deck boards running vertically from the back of the house and out.

Is this over-engineered?? I desperately need to know.

Having looked at about a thousand web sites the closest I have come to making this more simple is to simply attach cut-down joists at 400mm centres 'in between' the 2x6 beams. Does that make sense? In other words the joist would be attached (screws or hangers) by butting up to the 2x6 beams. This would mean that instead of having 4m joists running on top of the beams and horizontal to the house I would have roughly 2, 2 metre joists slotted between the beams - running horizontal to the house.

The only thing I am pretty much fixed on is that I will be using posts to support everything. It's the framework that is really confusing me.

I know having a 3 tier system (bearers, joists and decking) is the most rigid method of doing this but is it overkill?

BTW- The bearers would only be hovering 2 inches off the floor.

I really hope someone can help. Thanks for reading.