Gaz, Just couple points to clear up first.

Fredddy I list a quote below of yours posted today on another thread in Building.

Quote.

I really don't know what all the fuss about is, this is some official blurb from Kingspan

http://www.insulation.kingspan.com/uk/pdf/refurb_booklet_2009.pdf page 15 or 16. I've used this spec in plenty of garage conversions and it gets approved every time.

Kingspans solution for a half brick skin is basically the same as what DD specified for Celotex, 50mm cavity, BM 12mm sheathing etc, etc.

Both pages you quote 15 and 16 from Kingspan are for a 215mm brick wall. Will agree that OP states (single brick wall), but I feel sure that he means single skin brick wall. In the other post where you posted this solution the OP clearly states single skin 102 brick wall consequently pages 15 and 16 do not apply.

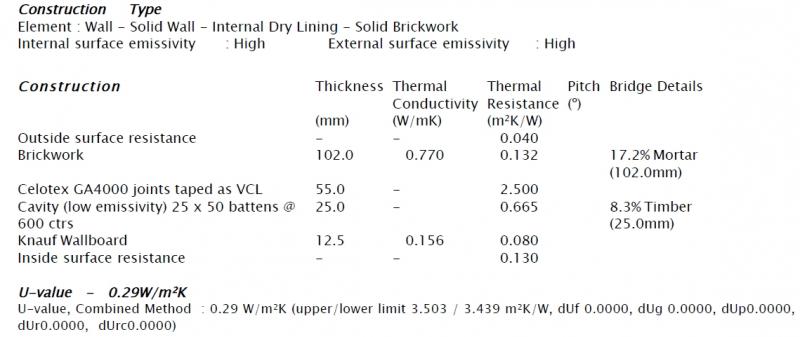

DD, I did not realise that 55mm celotex gave 2.50 resistance, but have checked it out for my own benefit, and you are correct, how ever can not make 55mm celotex stand up to a 0.29 U value best I can get is a U value of 0.35.

Gaz. Will give you two suggestions that have been approved for us in the past.. Unfortunately, what one area approves, the next area may not.

Both solutions are based on the fact that external wall is half brick skin with centre supporting pier.

Firstly both celotex and kingspan methods of battening out a wall are a load of old b******s.

Take your long wall first. Tack BM to top of wall with good vertical laps to joins and in corners and let hang down. We use Tyvex breathable felt.

Use 47x125mm for your stud partition. Reason for 125mm is so that you can sail across your supporting centre pier with your plasterboard.

Lay a 150mm dry dpc and throw your stud partition up at 600mm centres. Difficult to explain on paper, but give a lot of thought to position of stud in the corner where it will pick up back wall return studwork. If you do not get it right, then your centres are all up the creek. If BC are concerned about you fixing your bottom plate down through the dpc, then screw300mm lengths of fir band at right angles every 600mm to underside of sole plate and fix to oversite concrete. These will be covered by new floor.

Cut your 100mm celotex to sizes required and push into studwork. Before doing so rattle some 50mm nails into studwork 100mm back from face to act as stops.

Two ways now, depending on what your man will accept. Either tape all studwork and joints of celotex with 100mm aluminium foil tape or use visqueen as VCB.

Plaster board and skim. Your man may want plasterboard to be 12mm insulated.

Mention couple of other points. Have you given consideration to what you are doing with existing floor. Depends on floor level in relation to existing dpc. If installing kitchen into new work, fit noggins every where you need decent fixings, i.e. kitchen wall units etc.

One other thing, these so called modern tackers seem to have got into the habit of fixing plasterboards on studwork running with the studs, it is wrong. Plasterboard should be fixed across the studs, or across the joists.

Will post to-morrow the other approved way we have done it using blockwork.

oldun