Hi All,

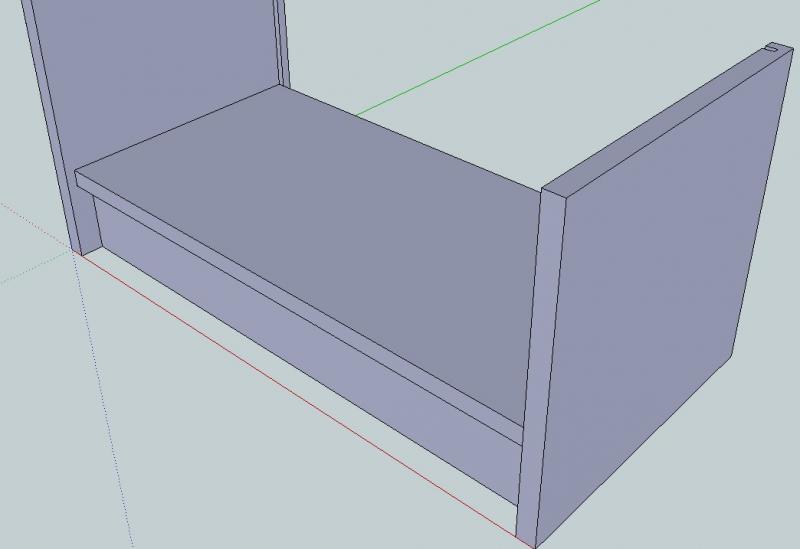

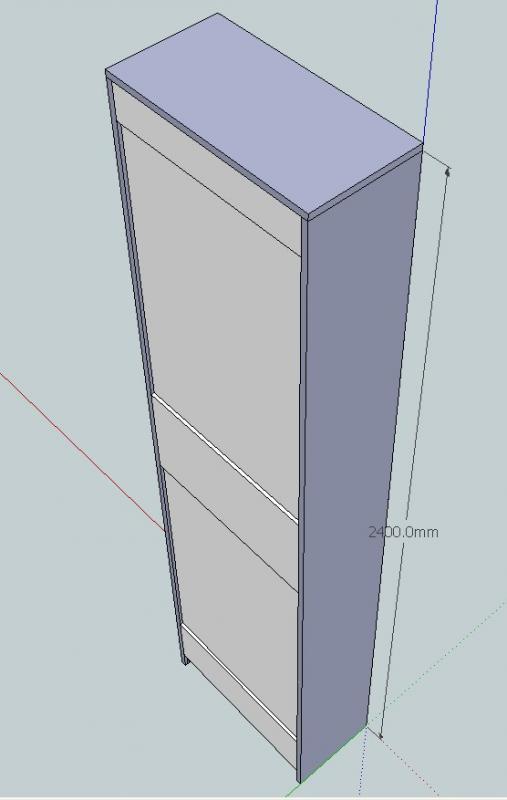

I am looking to build a floor to ceiling built in bookcase to create a study room.

I want it to be floor to ceiling along the entire length of one wall. There are two posts, one in each corner of the room on that wall - so looking to build it into that recess if that makes sense.

The wall is plasterboard on metal studs (new build property).

I am not sure which path to take. Do I do very long shelves on battens with spring toggles behind the plasterboard - would this support (plasterboard is 15mm thick). Do I build a frame type thing similar in the way that stud walls are created.

Please can people offer suggestions, tips, tricks and advice to give me a starting point?

Many thanks in advance.

BrennaBoy.

I am looking to build a floor to ceiling built in bookcase to create a study room.

I want it to be floor to ceiling along the entire length of one wall. There are two posts, one in each corner of the room on that wall - so looking to build it into that recess if that makes sense.

The wall is plasterboard on metal studs (new build property).

I am not sure which path to take. Do I do very long shelves on battens with spring toggles behind the plasterboard - would this support (plasterboard is 15mm thick). Do I build a frame type thing similar in the way that stud walls are created.

Please can people offer suggestions, tips, tricks and advice to give me a starting point?

Many thanks in advance.

BrennaBoy.