Can anyone please advise?

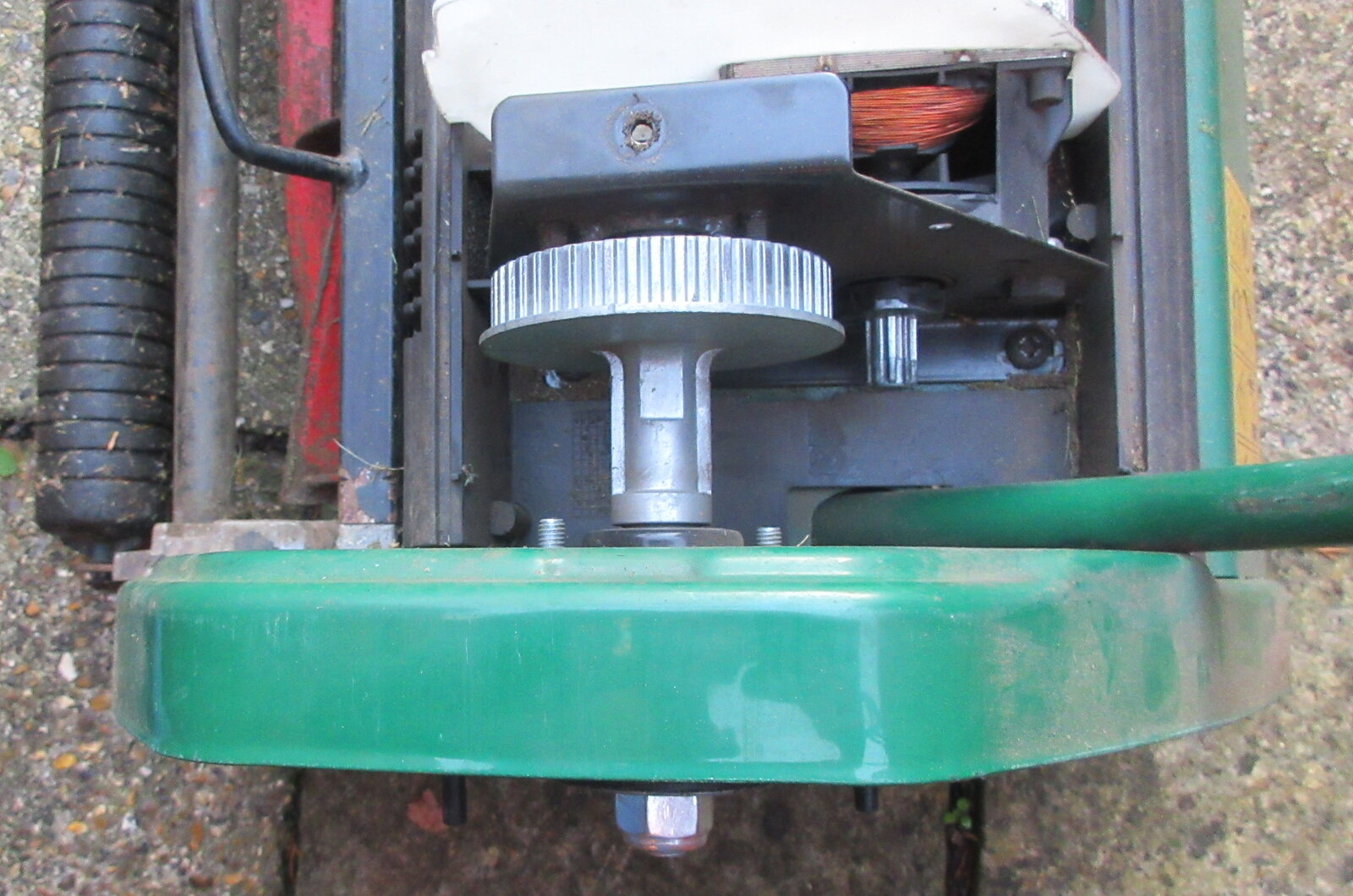

The toothed drive belt has broken on my Suffolk Punch Classic Electric 30 mower. this is not the easily replaced outside drive belt but the one which motor drive to the main drive shaft which operates the cutting cylinder.

i cannot see how to dismantle the upper shaft enough to enable me to slip the new belt into place. I would appreciate any advice. I have attached 3 photos to show the location of the belt.

Many thanks

The toothed drive belt has broken on my Suffolk Punch Classic Electric 30 mower. this is not the easily replaced outside drive belt but the one which motor drive to the main drive shaft which operates the cutting cylinder.

i cannot see how to dismantle the upper shaft enough to enable me to slip the new belt into place. I would appreciate any advice. I have attached 3 photos to show the location of the belt.

Many thanks