- Joined

- 24 Feb 2007

- Messages

- 558

- Reaction score

- 3

- Country

Hi there I wondered if you could help?

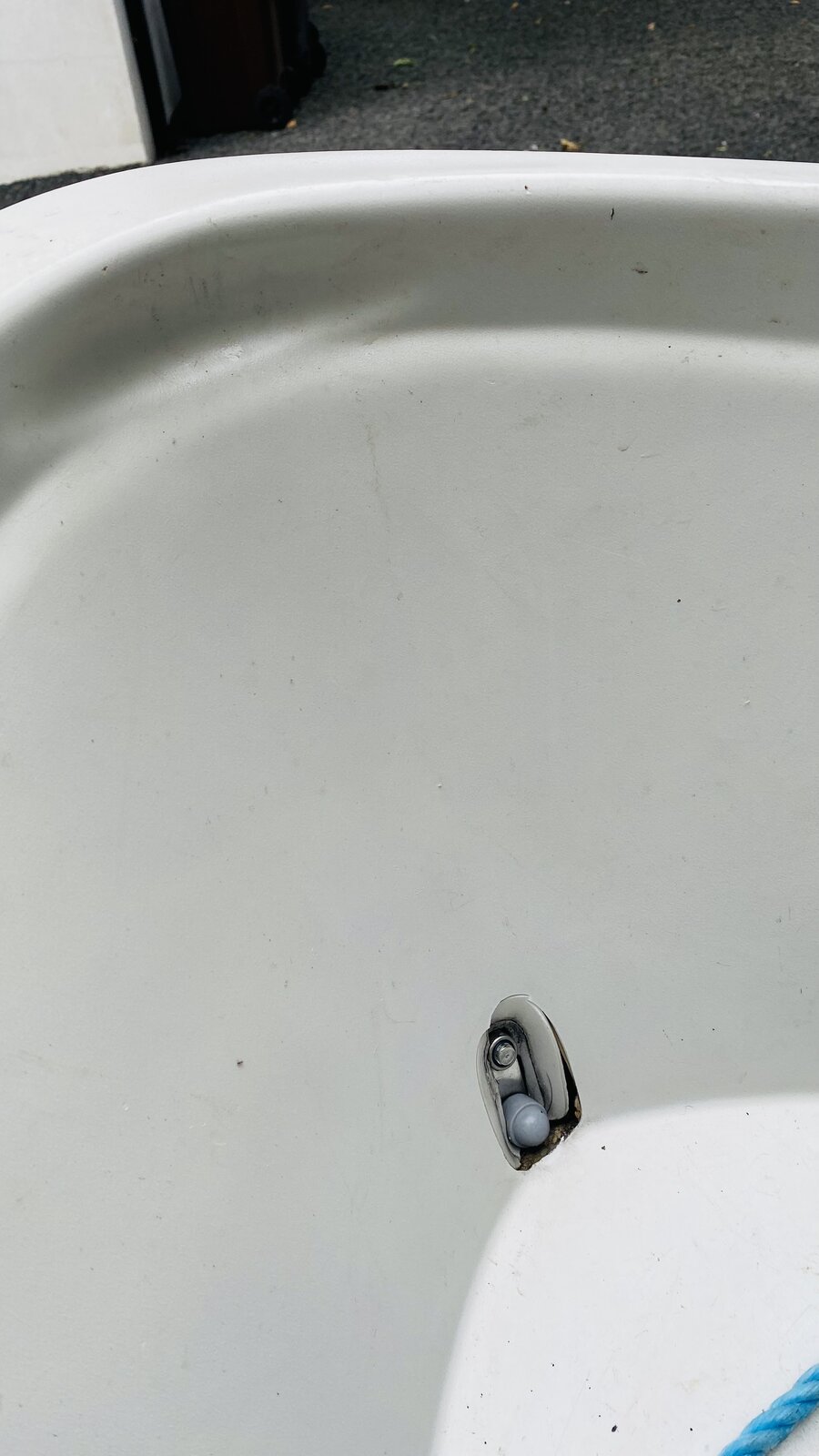

I’m looking for a piece of stainless steel to prevent pull through on the winch point of my boat. However I’m unsure how I could form this to match the contour? Is there anything you could suggest?

Many thanks,

Steve.

Steve.

I’m looking for a piece of stainless steel to prevent pull through on the winch point of my boat. However I’m unsure how I could form this to match the contour? Is there anything you could suggest?

Many thanks,