- Joined

- 31 Jan 2023

- Messages

- 39

- Reaction score

- 3

- Country

My air separator (Tower AIR22CF with cold feed) is blocked with magnetite, not an issue. A straightforward simple replacement along with some associated pipework to keep things new, shiny and clean, so I thought.

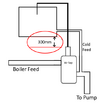

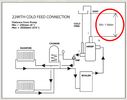

I was looking at the specs Tower provide and note they state a minimum distance of 1 metre between the bottom of the F&E tank to the air sep (see pic). On my existing system (and the other 200 odd fitted to all the houses on the development) the distance is around 300-400mm (see pic).

I’ve not become aware that this has caused issues for other residents over the past 15 years, so why do Tower state 1 metre?

PS, I could replace with a combined feed / vent or seal it up. But I want to keep the vented system for now due to cost and other reasons.

I was looking at the specs Tower provide and note they state a minimum distance of 1 metre between the bottom of the F&E tank to the air sep (see pic). On my existing system (and the other 200 odd fitted to all the houses on the development) the distance is around 300-400mm (see pic).

I’ve not become aware that this has caused issues for other residents over the past 15 years, so why do Tower state 1 metre?

PS, I could replace with a combined feed / vent or seal it up. But I want to keep the vented system for now due to cost and other reasons.