Hi can anyone help me with a problem with my IDEAL ISAR HE30 boiler.

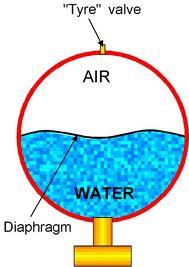

When CH is on pressure on gauge rises to above 3 bar within 15mins & then leaks via PRV & out thru pipe outside, needing to refill to 1bar when cold. So far had 2 different engineers, 1st said faulty pressure gauge, then he said expansion vessel which he then changed.

Problem still existed, so he suggested power flush of CH system as there is a blockage somewhere. I didnt agree, as all rads & pipework get hot & so does all pipework.

As under insurance they refused to assist any further. So I called another engineer who stated that PRV was leaking even when pressure had only reached 2bar, so he replaced PRV which he said old PRV was faulty. He left system working but had turned down CH thermostat on boiler, so heating was not warm enough. I turned up dial, & problem is still the same.

Since, I have noticed that from system being cold, when turning on HW, CH flow pipe from boiler immediately gets hot & so does flow pipe on nearest radiator.

Finally, this morning, boiler was showing error code L alternating with F, so no HW or CH. Pressed reset button, worked briefly, so tried again and has since been error code free, but with same rising pressure etc.

Can anyone please help/suggest what could be wrong, as this saga started 7 weeks ago.

Thanks in advance

When CH is on pressure on gauge rises to above 3 bar within 15mins & then leaks via PRV & out thru pipe outside, needing to refill to 1bar when cold. So far had 2 different engineers, 1st said faulty pressure gauge, then he said expansion vessel which he then changed.

Problem still existed, so he suggested power flush of CH system as there is a blockage somewhere. I didnt agree, as all rads & pipework get hot & so does all pipework.

As under insurance they refused to assist any further. So I called another engineer who stated that PRV was leaking even when pressure had only reached 2bar, so he replaced PRV which he said old PRV was faulty. He left system working but had turned down CH thermostat on boiler, so heating was not warm enough. I turned up dial, & problem is still the same.

Since, I have noticed that from system being cold, when turning on HW, CH flow pipe from boiler immediately gets hot & so does flow pipe on nearest radiator.

Finally, this morning, boiler was showing error code L alternating with F, so no HW or CH. Pressed reset button, worked briefly, so tried again and has since been error code free, but with same rising pressure etc.

Can anyone please help/suggest what could be wrong, as this saga started 7 weeks ago.

Thanks in advance