hi,

i've had someone look at my heating system recently and he wants to combine the feed and vent pipes to help eliminate the air and other problems i have been experiencing over the last year following a boiler and pump upgrade.

he also wants to remove the vent. arm above the F and E tank which i'm unsure this the right thing to do ?

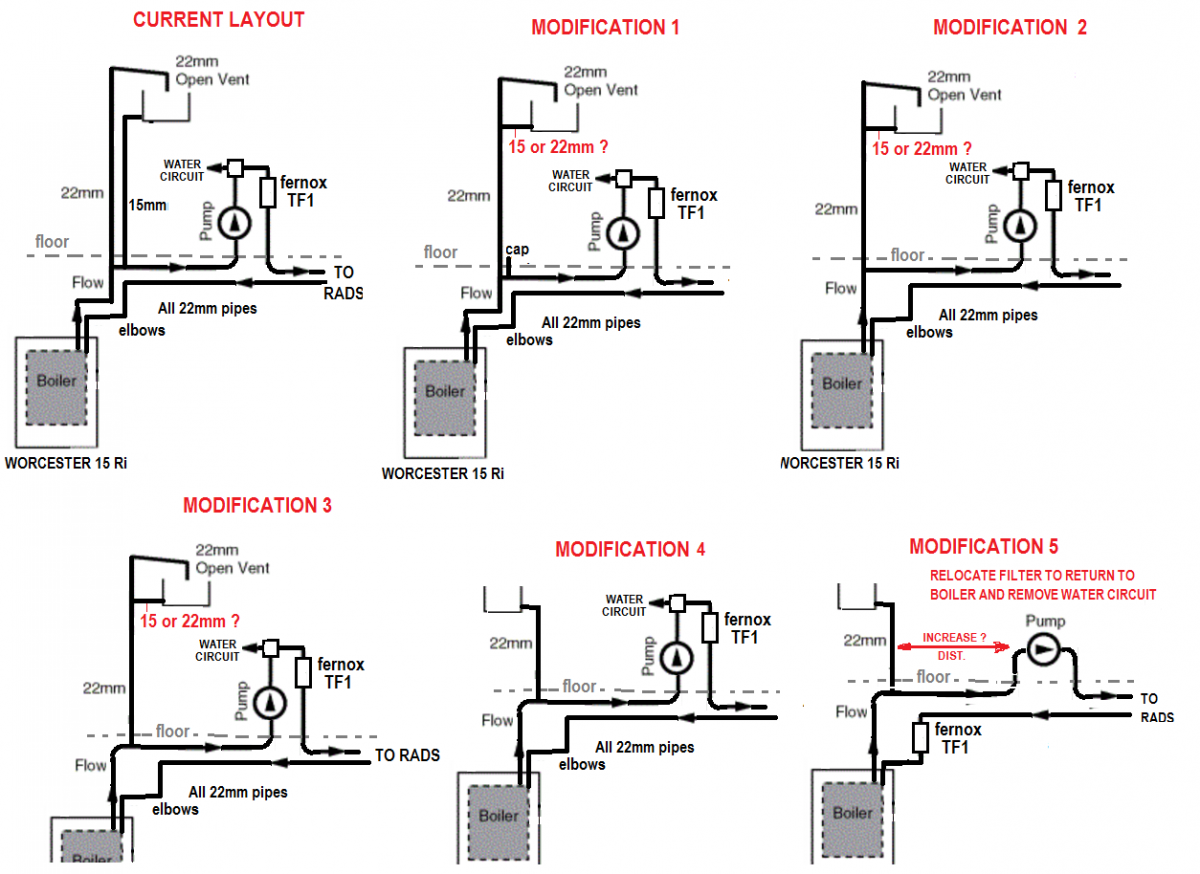

here's some drawings of my system and possible modifications:

the system is 35 years old and a Y plan, i don't think it has a bypass valve fitted.

there are 8 rads. with just 3 trv's fitted in the bedrooms,

the boiler was upgraded several years ago along with a filter and new pump.

i have had many problems , my main concern is air getting in the system also in the winter i'm having to continually adjust things to keep it running.

i have done everything i can to the rest of the system so now i'm thinking to improve the pipework around the boiler,pump and improving the feed and vent ?

please advise ,

chris

i've had someone look at my heating system recently and he wants to combine the feed and vent pipes to help eliminate the air and other problems i have been experiencing over the last year following a boiler and pump upgrade.

he also wants to remove the vent. arm above the F and E tank which i'm unsure this the right thing to do ?

here's some drawings of my system and possible modifications:

the system is 35 years old and a Y plan, i don't think it has a bypass valve fitted.

there are 8 rads. with just 3 trv's fitted in the bedrooms,

the boiler was upgraded several years ago along with a filter and new pump.

i have had many problems , my main concern is air getting in the system also in the winter i'm having to continually adjust things to keep it running.

i have done everything i can to the rest of the system so now i'm thinking to improve the pipework around the boiler,pump and improving the feed and vent ?

please advise ,

chris