There is a very cold draught coming from the access hole for the suppy pipe to our gas fire. We noticed it last year, but this year I've decided to do something about it. I am unsure if it is coming from the sleeve or the cavity though. The supply pipe is sealed where it enters the outside wall, so I can only assume the draught is from the cold air in the cavity.

However this has led me to question the installation of the fire -

The installation instructions specifically state in an "Important Note"

"If rear entry gas supply connection is required, then it MUST be installed prior to the installation of the heater into the wall. If any pipe is run in or through the cavity, a factory sleeved pipe must be used and sealed where the pipe enters the fire and/or cavity"

The gas regulations (regulation 19) state

"(4) Paragraph (3) shall not apply to the installation of installation pipework

connected to a living flame effect fire provided that the pipework in the cavity is as

short as is reasonably practicable, is enclosed in a gas tight sleeve and sealed at

the joint at which the pipework enters the fire; and in this paragraph a “living flame

effect gas fire” means a gas fire -

(a) designed to simulate the effect of a solid fuel fire;

(b) designed to operate with a fanned flue system; and

(c) installed within the inner leaf of a cavity wall."

So the instructions say and/or, but the regulations say must be in a gas tight sleeve and sealed at the joint at which it enters the fire.

If I have the right regulations and understand them, I would expect the sleeve to be sealed at the fire, to prevent any escaping gas to collect in the cavity between plasterboard and exterior boarding of the house. Which would give the added benefit of preventing any draughts coming in.

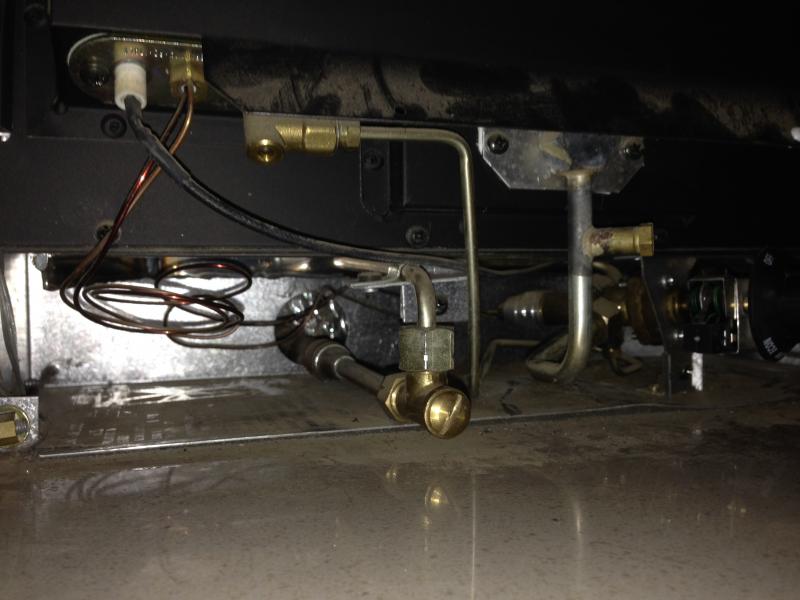

I've attached images in which you can see the hole in the fire to accept the supply pipe, and also close ups showing the supply pipe in it's sleeve, stopping short of the fire and also resting on the bottom of the hole it is meant to come through.

If I was installing it, I wouldn't be happy it was resting on a narrow bit of metal for fear of it wearing through, although I would hope there isn't that much movement in the house.

I would be grateful for a corgi registered persons opinion on how to interpret the manual and the regulations.

Primarily, I want to stop the draught, but if the fire isn't installed as it should be, I want to address that issue also. Mainly by approaching the builder, having them rectify it, or remove the fire completely and repair the wall.

If I seal the pipe where it enters the fire, I will then have an unsleeved pipe in the cavity - which would be against regulations, and dangerous in the event of a leak?

Worst case scenario - however unlikely

Supply pipe wears on thin metal that forms access hole to the fire.

Gas leaks up into cavity between plasterboard inner wall and damp proof lines sterling board stuff between plasterboard and blockwork.

Gas ignites and side of house falls off.

assuming we weren't home at the time - how would the insurance handle a claim for an damage that could have been prevented if the fire was installed properly.

However this has led me to question the installation of the fire -

The installation instructions specifically state in an "Important Note"

"If rear entry gas supply connection is required, then it MUST be installed prior to the installation of the heater into the wall. If any pipe is run in or through the cavity, a factory sleeved pipe must be used and sealed where the pipe enters the fire and/or cavity"

The gas regulations (regulation 19) state

"(4) Paragraph (3) shall not apply to the installation of installation pipework

connected to a living flame effect fire provided that the pipework in the cavity is as

short as is reasonably practicable, is enclosed in a gas tight sleeve and sealed at

the joint at which the pipework enters the fire; and in this paragraph a “living flame

effect gas fire” means a gas fire -

(a) designed to simulate the effect of a solid fuel fire;

(b) designed to operate with a fanned flue system; and

(c) installed within the inner leaf of a cavity wall."

So the instructions say and/or, but the regulations say must be in a gas tight sleeve and sealed at the joint at which it enters the fire.

If I have the right regulations and understand them, I would expect the sleeve to be sealed at the fire, to prevent any escaping gas to collect in the cavity between plasterboard and exterior boarding of the house. Which would give the added benefit of preventing any draughts coming in.

I've attached images in which you can see the hole in the fire to accept the supply pipe, and also close ups showing the supply pipe in it's sleeve, stopping short of the fire and also resting on the bottom of the hole it is meant to come through.

If I was installing it, I wouldn't be happy it was resting on a narrow bit of metal for fear of it wearing through, although I would hope there isn't that much movement in the house.

I would be grateful for a corgi registered persons opinion on how to interpret the manual and the regulations.

Primarily, I want to stop the draught, but if the fire isn't installed as it should be, I want to address that issue also. Mainly by approaching the builder, having them rectify it, or remove the fire completely and repair the wall.

If I seal the pipe where it enters the fire, I will then have an unsleeved pipe in the cavity - which would be against regulations, and dangerous in the event of a leak?

Worst case scenario - however unlikely

Supply pipe wears on thin metal that forms access hole to the fire.

Gas leaks up into cavity between plasterboard inner wall and damp proof lines sterling board stuff between plasterboard and blockwork.

Gas ignites and side of house falls off.

assuming we weren't home at the time - how would the insurance handle a claim for an damage that could have been prevented if the fire was installed properly.