Hi Folks,

I need a couple of tips for a front door I’m replacing which will have side and top glazed panels as well as the Rockdoor door frame/slab - very happy with the general approach to take but some areas have a few options which I can’t decide on.

This will be checked by building control as part of a larger piece of work so doesn’t need to be FENSA registered, hence why I’m saving cash, I have a friend to assist who has done these before.

Queries are:

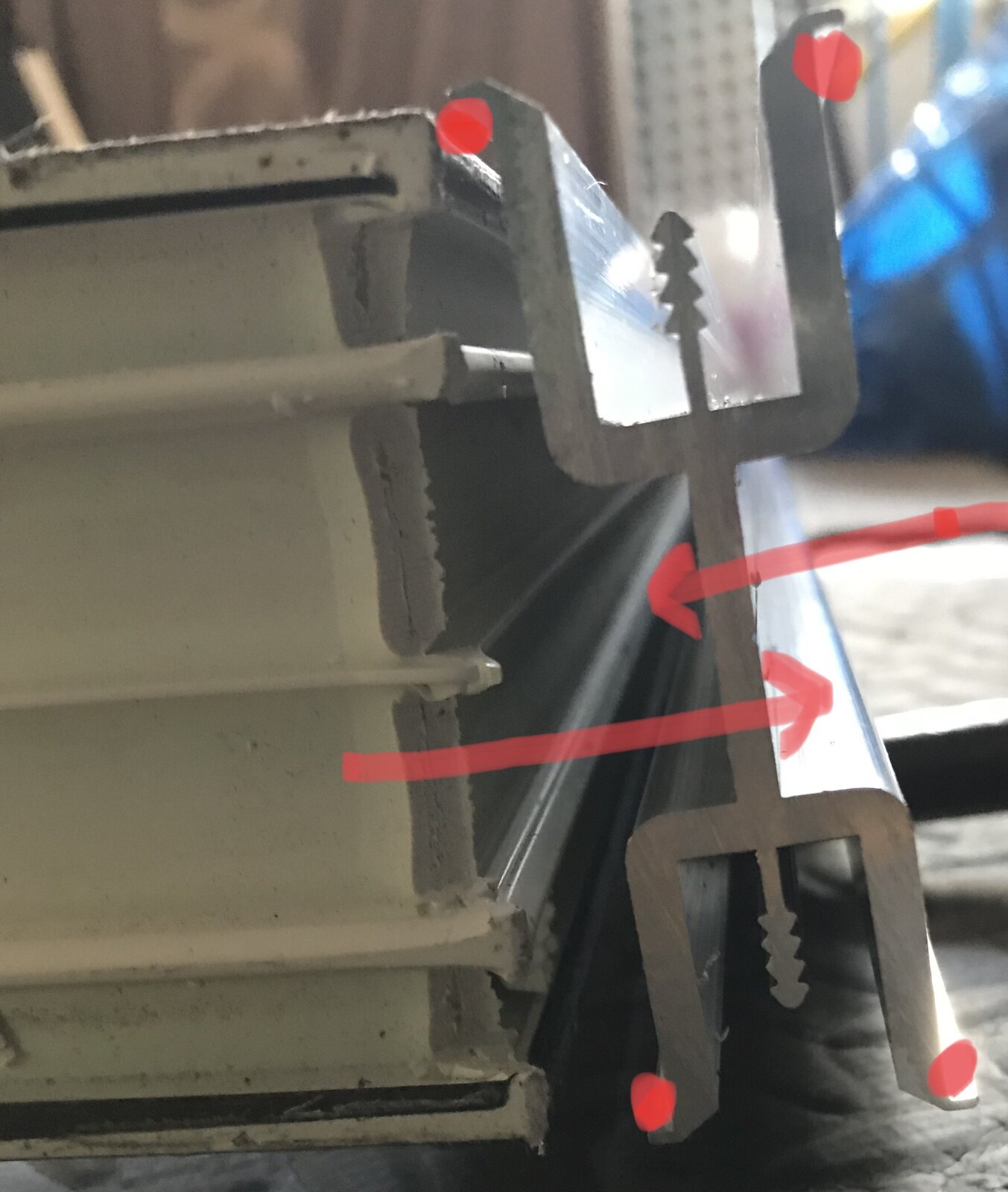

1. Photo hopefully attached of Rehau profile and aluminium coupler - I’m thinking a bead of silicon in the 4 areas I’ve marked with a red blob, to ensure no water ingress behind the plastic cover, and baypole screws (50mm?) through the Rehau on each side, ever so slightly off centre so as to keep away from the centre bump on the Rehau profile but still go through the centre part of the coupler (as marked in the picture) and stop before hitting the opposite Rehau. Right approach, wrong approach?

2. The Rehau outer frame will have a steel reinforcement in it. Is this likely to cause a problem with the Baypole screws going through? I’m unclear where exactly this reinforcement is.

3. Brick fixings - 110mm 7.5mm concrete screws on their own with a 6mm pilot hole (my thinking) or the frame screws with the plastic sheath?

4. Damp - the cill will sit on brick with concrete next to it inside the house, and there is no cavity wall at this location and as far as I am aware no DPM. I don’t think I have the room to sit packers under the cill (apart from to ensure its level). I’m thinking a sheet of DPM under the cill and running above the brick and concrete to protect the laminate floor inside from any moisture hitting it.

5. Packers - are bridge packers crucial for the bottom of the glazings rather than standard flat packers, for air or water flow?

Greatly appreciate the advice folks.

I need a couple of tips for a front door I’m replacing which will have side and top glazed panels as well as the Rockdoor door frame/slab - very happy with the general approach to take but some areas have a few options which I can’t decide on.

This will be checked by building control as part of a larger piece of work so doesn’t need to be FENSA registered, hence why I’m saving cash, I have a friend to assist who has done these before.

Queries are:

1. Photo hopefully attached of Rehau profile and aluminium coupler - I’m thinking a bead of silicon in the 4 areas I’ve marked with a red blob, to ensure no water ingress behind the plastic cover, and baypole screws (50mm?) through the Rehau on each side, ever so slightly off centre so as to keep away from the centre bump on the Rehau profile but still go through the centre part of the coupler (as marked in the picture) and stop before hitting the opposite Rehau. Right approach, wrong approach?

2. The Rehau outer frame will have a steel reinforcement in it. Is this likely to cause a problem with the Baypole screws going through? I’m unclear where exactly this reinforcement is.

3. Brick fixings - 110mm 7.5mm concrete screws on their own with a 6mm pilot hole (my thinking) or the frame screws with the plastic sheath?

4. Damp - the cill will sit on brick with concrete next to it inside the house, and there is no cavity wall at this location and as far as I am aware no DPM. I don’t think I have the room to sit packers under the cill (apart from to ensure its level). I’m thinking a sheet of DPM under the cill and running above the brick and concrete to protect the laminate floor inside from any moisture hitting it.

5. Packers - are bridge packers crucial for the bottom of the glazings rather than standard flat packers, for air or water flow?

Greatly appreciate the advice folks.