D

Deleted member 212919

Hi,

Bought a basic close-coupled toilet online, and planning to install myself after watching youtube videos of how it's done (although I will call in a professional if I make a pigs-ear of it).

I have two concerns though:

1. Tiled floor is not completely even, so pan 'rocks' slightly. I need to put something on the lower tile to pad it out (the equivalent of some folded paper under a table leg). What could I used that would stay in place and not deteriorate? Maybe glueing a strip of roofing felt, or bike tyre innertube?

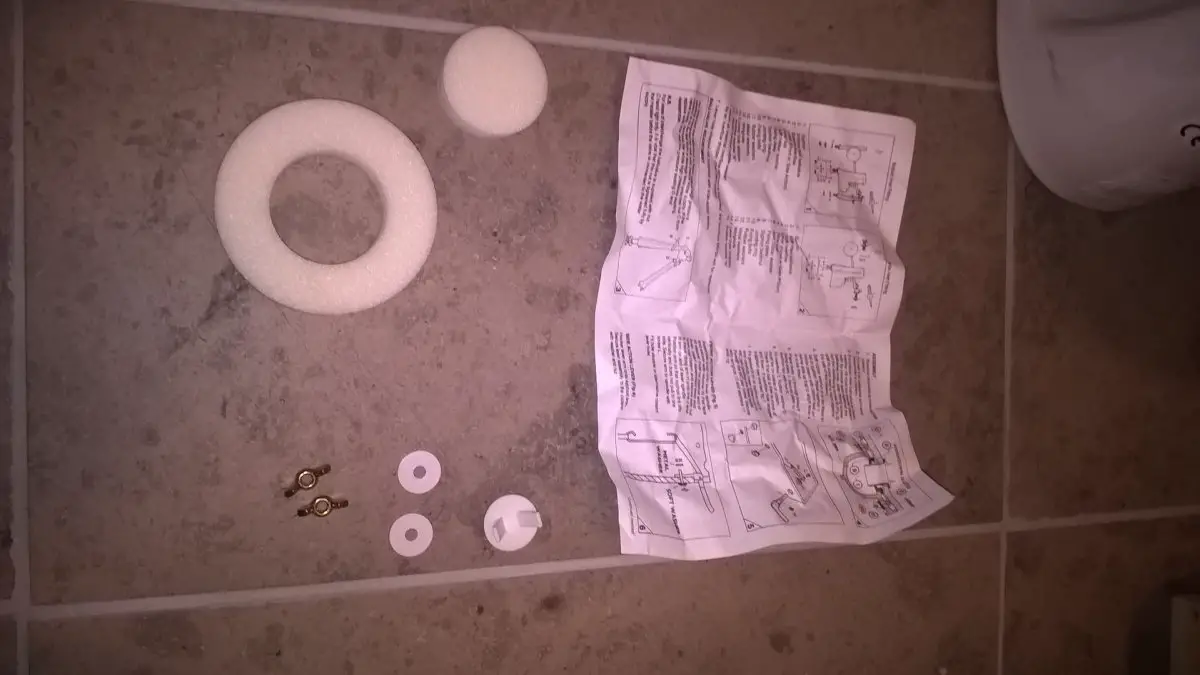

2. The instructions that came with the toilet make no sense, and it looks like most of the cistern fittings have already been done. All that came in the fittings bag was two washers, two wingnuts, and a foam ring. It looks like I just have to put this foam ring between cistern and pan, and fix with the wing nuts. Will this foam ring even be watertight and last long? All the youtube videos I saw showed a solid plastic or rubber ring to be used here.

See photos.

Bought a basic close-coupled toilet online, and planning to install myself after watching youtube videos of how it's done (although I will call in a professional if I make a pigs-ear of it).

I have two concerns though:

1. Tiled floor is not completely even, so pan 'rocks' slightly. I need to put something on the lower tile to pad it out (the equivalent of some folded paper under a table leg). What could I used that would stay in place and not deteriorate? Maybe glueing a strip of roofing felt, or bike tyre innertube?

2. The instructions that came with the toilet make no sense, and it looks like most of the cistern fittings have already been done. All that came in the fittings bag was two washers, two wingnuts, and a foam ring. It looks like I just have to put this foam ring between cistern and pan, and fix with the wing nuts. Will this foam ring even be watertight and last long? All the youtube videos I saw showed a solid plastic or rubber ring to be used here.

See photos.