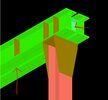

Helping someone with some house building work. He has recently had a window fitter that has installed rsj 178 x 102 x 19 siting on each side of the wall as it a solid wall without cavity. Is it okay to fill the cavity between the 2 rsj (I beam) with expanding foam to make sure no ingress of water as he has seen some drops in heavy rain and help with coldbridge too

Attachments

Last edited: