Hi all,

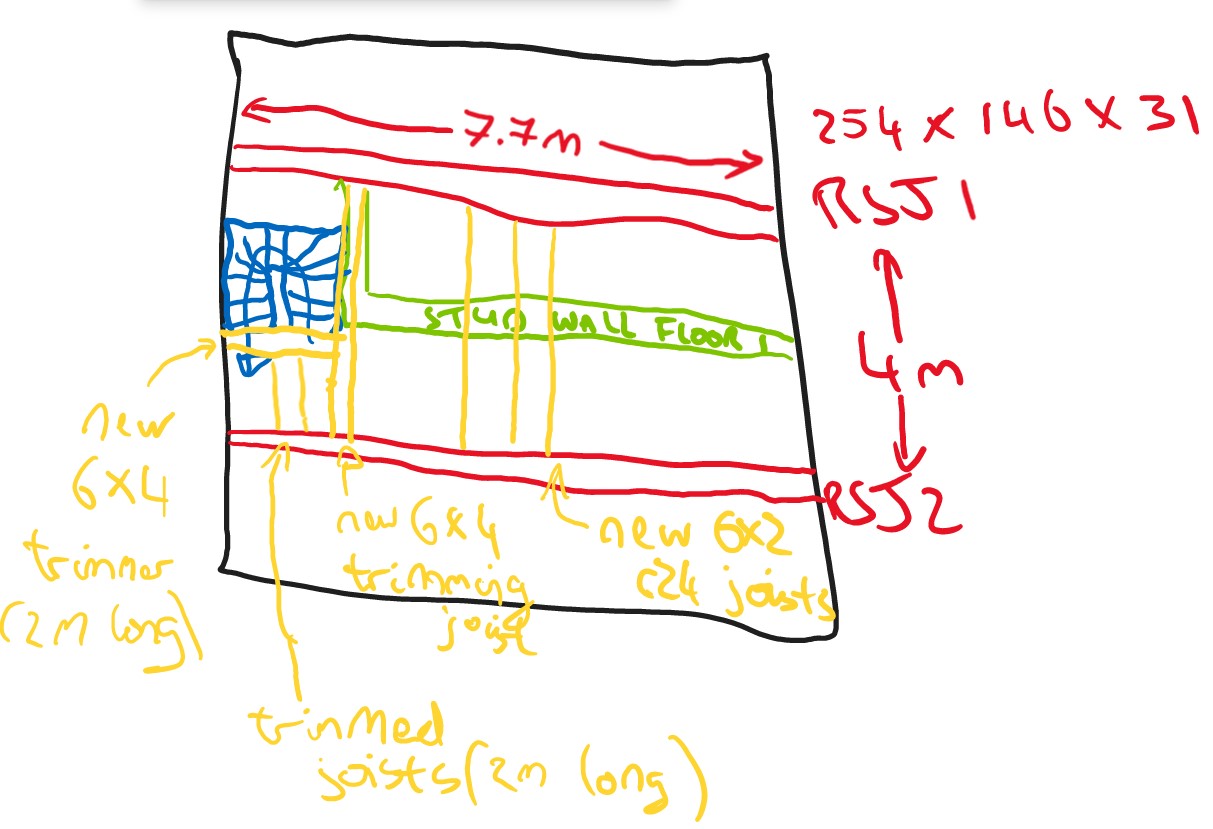

I'm converting a loft and have hung 6x2 c24 joists between 2 steel beams (that go from gable to gable). The 6x2s rest on a central wall at first floor level. I wanted to keep the joists as low as possible to maximise headroom.

For the stairs trimming and trimmer joists, I have 2 questions:

1/ Will a 6x4 do the job for both the trimmer and trimming joists? I can find span tables for ordinary joists with standard floor loadings but not for a load from trimmed joists and a stairs.

2/ What is the standard way of fixing the trimmer into the gable block wall? Is it cutting a pocket (like with the steels) or to cut a slot and point a masonry joist hanger into it?

Thanks!

I'm converting a loft and have hung 6x2 c24 joists between 2 steel beams (that go from gable to gable). The 6x2s rest on a central wall at first floor level. I wanted to keep the joists as low as possible to maximise headroom.

For the stairs trimming and trimmer joists, I have 2 questions:

1/ Will a 6x4 do the job for both the trimmer and trimming joists? I can find span tables for ordinary joists with standard floor loadings but not for a load from trimmed joists and a stairs.

2/ What is the standard way of fixing the trimmer into the gable block wall? Is it cutting a pocket (like with the steels) or to cut a slot and point a masonry joist hanger into it?

Thanks!