Hi all,

I've recently been prepping a room to lay a reclaimed pine floor. Work so far is:

- old laminate floor ripped up and old boards removed (the room is actually 3 separate areas knocked in to one some time ago).

- joists replaced where need be and packed out/levelled

- reclaimed boards sanded and cleaned to useable state. Any rotten sections have been cut out.

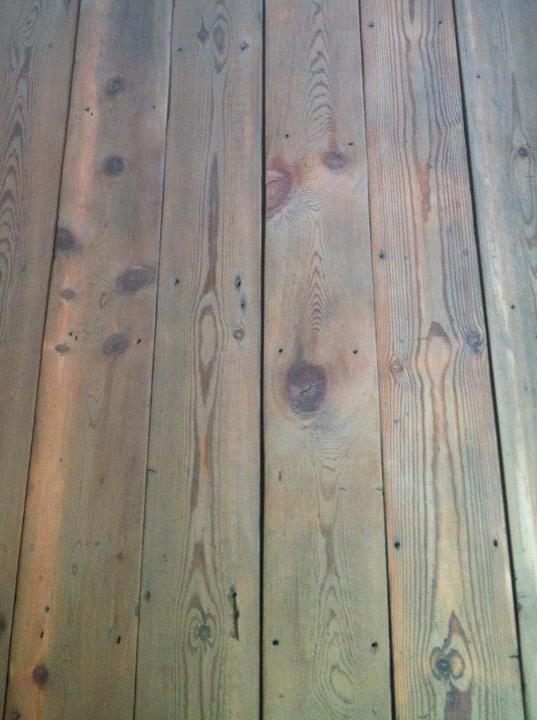

The boards themselves look gorgeous! They have a nice dull honey colour.

I am basically ready to nail them down, having laid them in the room and cut them to suitable lengths. The boards are not T&G and are instead square cut.

My question is, what should I use to nail them down? Is a nailgun suitable or do I risk ruining all of my hand work so far? Is predrilling and nailing a better idea?

Any advice would be really appreciated.

Many thanks

Jon

I've recently been prepping a room to lay a reclaimed pine floor. Work so far is:

- old laminate floor ripped up and old boards removed (the room is actually 3 separate areas knocked in to one some time ago).

- joists replaced where need be and packed out/levelled

- reclaimed boards sanded and cleaned to useable state. Any rotten sections have been cut out.

The boards themselves look gorgeous! They have a nice dull honey colour.

I am basically ready to nail them down, having laid them in the room and cut them to suitable lengths. The boards are not T&G and are instead square cut.

My question is, what should I use to nail them down? Is a nailgun suitable or do I risk ruining all of my hand work so far? Is predrilling and nailing a better idea?

Any advice would be really appreciated.

Many thanks

Jon