Hello,

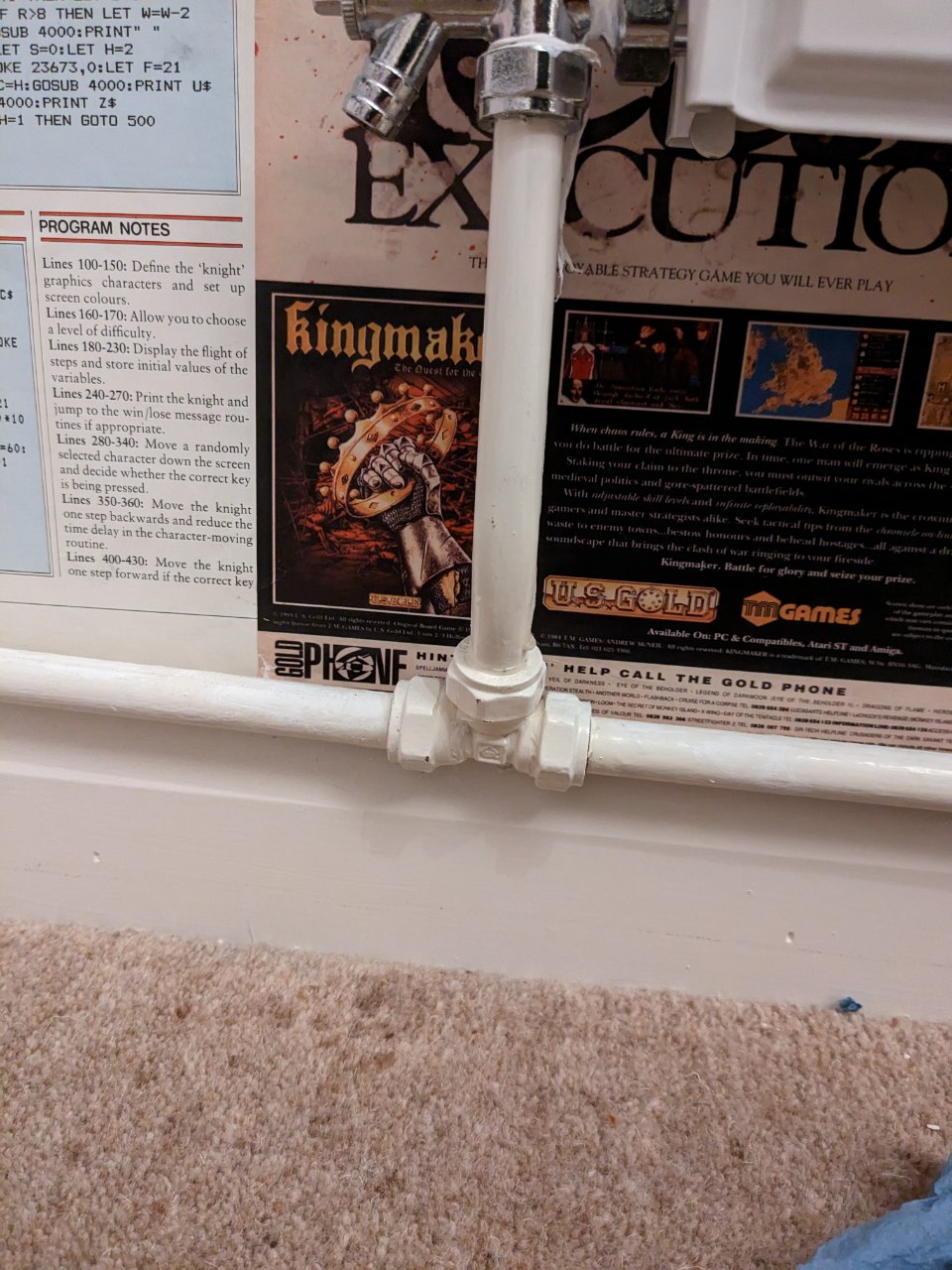

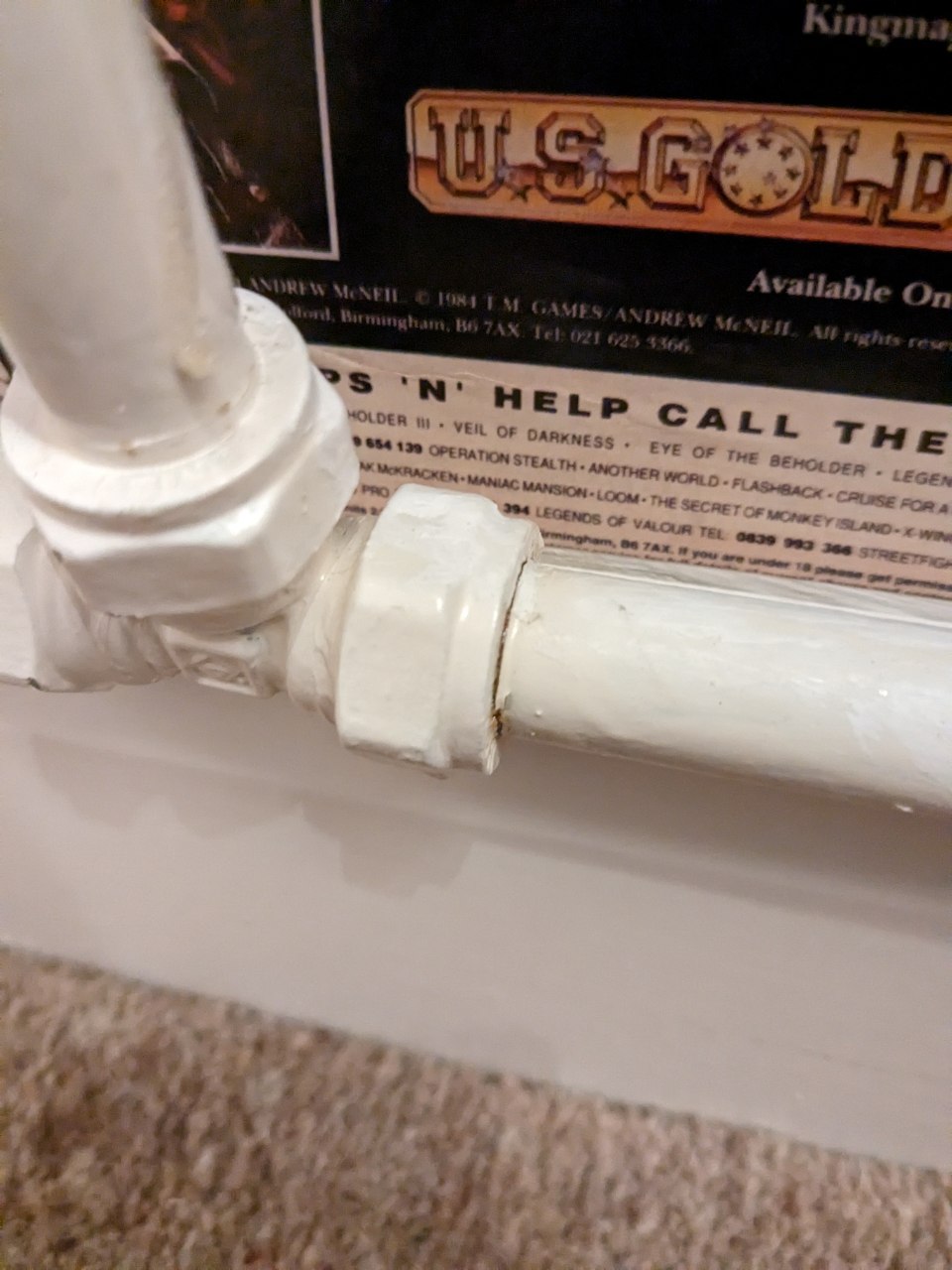

Took a radiator off the wall to properly decorate behind it. After putting it back on, this join in the pipe is sightly leaking. I guess from all the movement in the pipework taking the radiator off and on. Are there any simple things I can do to seal the joins?

Thanks!

Took a radiator off the wall to properly decorate behind it. After putting it back on, this join in the pipe is sightly leaking. I guess from all the movement in the pipework taking the radiator off and on. Are there any simple things I can do to seal the joins?

Thanks!