Consumer unit is already in place but nothing connected other than the mains in. It has 32, 16 and one 6amp circuit breakers.

6A breakers are normally used for lighting circuits in the UK.

New circuits are unfortunately notifiable to building control, this does get a bit silly sometimes, adding extra lights to an existing circuit would not be notifable (at least in england and wales), but I don't think a breaker with nothing connected to it can reasonably be regarded as a circuit, even if the intent was for it to be used to supply lighting.

Fixed wiring should always contain an earth conductor which should be connected to the earthing system. Even if the currently installed loads do not require an earth connection.

Wiring should be adequately secured such that stress on terminals is unlikely. There are various ways to achieve that. Generally for fixed wiring in the UK we rely on fixing the cables to the building structure, running them inside trunking/conduit etc. For loops of flex connecting to loads, a cord grip or gland of some sort is probably the most appropriate method.

Fixed wiring should also be secured such that premature collapse in the event of a fire is avoided. That generally means if you are running surface cables at high level (across ceilings, above doorways etc) then you should be using a proportion of metal fixings.

Most domestic fixed wiring in the UK is done with Twin and Earth cable. The earth conductor in this should be sleeved with earth sleeving at terminations.

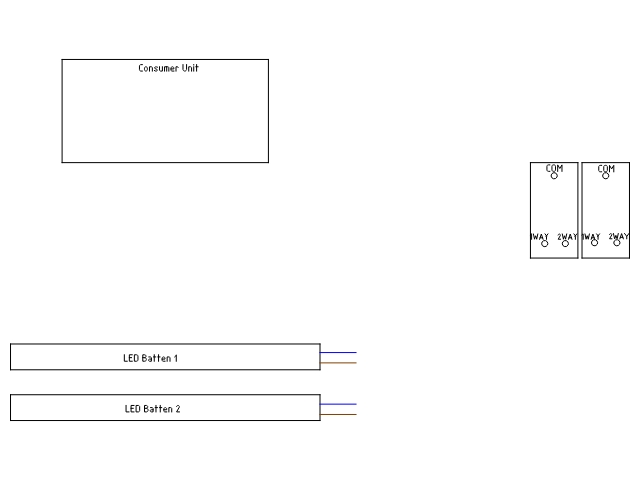

The batten lights have blue and brown fly leads.

You will need to install some sort of suitable junction or outlet box close to the lights, there are various things that could be used, What will look neatest may depend on how exactly the garage is built. Generally I would not consider the "oldschool" round junction boxes, suitable for this application. They have no cable restraint for the flex loops to the lights and they put all the wires for each pole in one big terminal which is not ideal when you have mixed conductor types (e.g. solid cores from fixed wiring cables and stranded cores from the flexible tail on the lights).

A ceiling rose would work fine, though may look a little strange, So would a flex outlet plate mounted on a backbox, so would some of the modern junction boxes with cord grips (though watch out that push-in terminals are generally not suitable for fine stranded wire). What exactly will look neatest will likely depend on the precise situation.

using the switch shown (it is shown viewed from the back).

Switches interrupt the live conductor to lights. Ignore the "2 way" terminal on the switches, that is only relavent when switching the same lights from multiple locations. You can treat the "Com" and "1 way" terminals as a simple on-off switch. Permanent live goes in one end, switched live comes out the other, it's not rocket surgery.

Broadly speaking there are two main options for wiring layouts. You can take the permanent live and neutral from the supply to the switch, then join the neutral in the switch and take the permanent live and neutral from the switch(es) to the lights.

Or you can bring the permanent live and neutral to the lights (or in your case, the outlet box near the lights), then take a "switch drop" which carries permanent live down to the switch and brings switched live back up. You can get special "twin brown" cable for this, but the more normal approach is to use normal cable, with the brown conductor used for permanent live and the blue for switched live.

You can join wires in an electrical box using oldschool terminal block or one of the newfangled push in or lever connectors. Though as-above be aware though that push-in connectors are generally not suitable for fine stranded wire.

I would also like to install an additional two LED batten lights and would like to know the best method to do this. Run them from a separate circuit breaker, or could they be linked together using the same type of switch?

No reason you can't run four lights from the same breaker.