Hi.

I'll start this with a little history.

My mum currently has some generic plastic drawer units. On top of one of these she has placed a 40l fish tank .

.

The fish tank is far too small for it inhabitants (4 fish, 3 of which are goldfish ). So she is getting a bigger tank, 98l, which she wanted to stand across 2 of these units

). So she is getting a bigger tank, 98l, which she wanted to stand across 2 of these units

I have successfully educated her into understanding that this is not a good idea, especially as the first unit is already showing stress fractures.

The problem we then faced is that she did not want to "re-organize" her drawer units. So apart from their sheer expense, we couldn't find anything suitable, so we decided to make some carcasses that take her existing drawers - this keeps her happy.

Now it is just a matter of design.

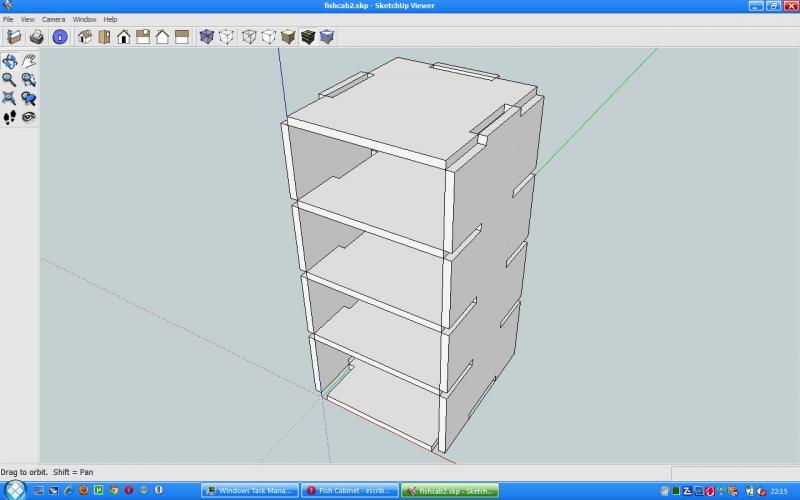

Overall we are going to build 2 separate (4 drawer) units as opposed to 1 (8 drawer) unit.

Our plan is to use 3/4" (18mm) MDF to make the sides, top, bottom and back, and then probably 1/4" (6mm) MDF for the shelves to take the existing drawers.

The plastic drawers are approximately 13" W x 15 1/2" D x 7" H.

This will give each unit overall dimensions of (approximately) 14 1/2" W x 16 1/4" D x 30 1/4" H

My plan to fix the shelves (as mother doesn't want any gaps between base of shelf and top of drawer - and the drawer side is the same height for its entire length) was to cut a notch in the side of the shelf and horizontal cuts in the front and rear of the side panels (and possibly do the same with the back) and then slot it all together.

My brother suggested a simpler solution, but requiring we reduce the sides and tops to 1/2" (12mm) MDF, then to use the 1/4" to clad the inside of the carcass and then rest the shelf on top of the cladding (for want of a better word). The reason for reducing to 1/2" is because mother does not want the extra 1" (over 2 carcasses) width. Even though it will fit. Because of this I was thinking that the top of the carcass would need to have the extra 1/4" as well.

My question is, based on the scant information I have supplied, do you think

And what would you recommend being the best way of fixing the sides and top together (bearing in mind I have no specialist equipment, just standard saws and drills).

I am sorry if I rambled a bit - I typed this in competition with the TV on in the background and my wife pestering me every 5 mins. Feel free to ask any questions.

I'll start this with a little history.

My mum currently has some generic plastic drawer units. On top of one of these she has placed a 40l fish tank

The fish tank is far too small for it inhabitants (4 fish, 3 of which are goldfish

I have successfully educated her into understanding that this is not a good idea, especially as the first unit is already showing stress fractures.

The problem we then faced is that she did not want to "re-organize" her drawer units. So apart from their sheer expense, we couldn't find anything suitable, so we decided to make some carcasses that take her existing drawers - this keeps her happy.

Now it is just a matter of design.

Overall we are going to build 2 separate (4 drawer) units as opposed to 1 (8 drawer) unit.

Our plan is to use 3/4" (18mm) MDF to make the sides, top, bottom and back, and then probably 1/4" (6mm) MDF for the shelves to take the existing drawers.

The plastic drawers are approximately 13" W x 15 1/2" D x 7" H.

This will give each unit overall dimensions of (approximately) 14 1/2" W x 16 1/4" D x 30 1/4" H

My plan to fix the shelves (as mother doesn't want any gaps between base of shelf and top of drawer - and the drawer side is the same height for its entire length) was to cut a notch in the side of the shelf and horizontal cuts in the front and rear of the side panels (and possibly do the same with the back) and then slot it all together.

My brother suggested a simpler solution, but requiring we reduce the sides and tops to 1/2" (12mm) MDF, then to use the 1/4" to clad the inside of the carcass and then rest the shelf on top of the cladding (for want of a better word). The reason for reducing to 1/2" is because mother does not want the extra 1" (over 2 carcasses) width. Even though it will fit. Because of this I was thinking that the top of the carcass would need to have the extra 1/4" as well.

My question is, based on the scant information I have supplied, do you think

- I have used the correct materials (MDF) - if not what

- Each unit will be strong enough to support an evenly distributed load of approx 50kg (98l + equipment across both carcasses)

And what would you recommend being the best way of fixing the sides and top together (bearing in mind I have no specialist equipment, just standard saws and drills).

I am sorry if I rambled a bit - I typed this in competition with the TV on in the background and my wife pestering me every 5 mins. Feel free to ask any questions.