Hi guys i need to move my kithecn radiator 20 cm to the right. as i understand , to do that first i need to bleed the radiator then after work refill it using the loop. i got Glow Worm Swifflow 75/80 boiler. after reading lots of post i made a list of the thing i need to do to complete the task. can you guys let me know if they are the right way.

1 make sure boiler is off at the electric main so boiler wont try to fire up.

2 find drain cock

3 fit hose and open cock,

4 open all air vents on radiators to let air in so system will drain properly, starting with the highest rad

5 close all air vents on rads, when drained.

6 carry out pipework

7 put recomended rust inhibitor in system via a radiator.

8 connect the filler loop

9 open filler loop, to re-fill system

10 vent all radiators, start with lowest rad

11 re open filler loop,continue filler loop and bleed until all rads done

9 switch on boiler.

do i need to check auto vent on boiler is open or close ???

also do i need to bleed the pump?

thanks again but appreciate, a final check of my checklist would be a great help.

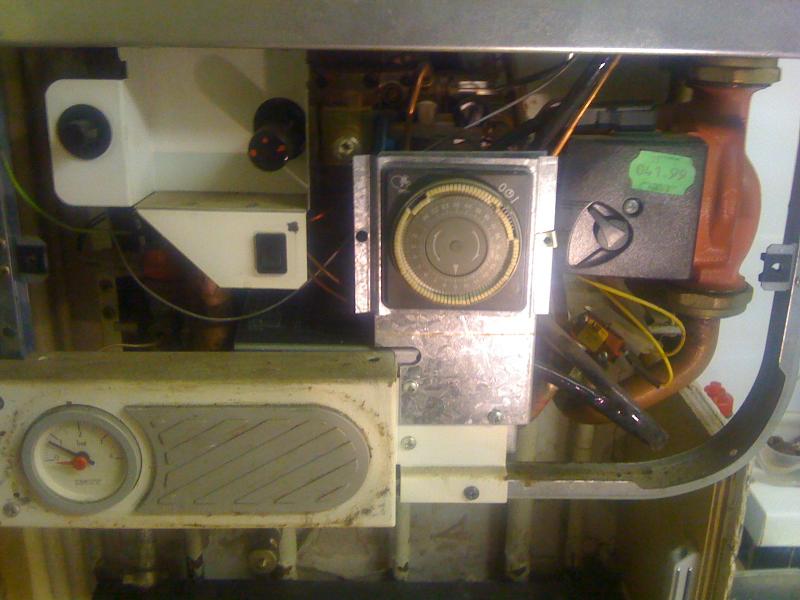

i have attached a photo of the radiator

![GALLERY]](http://[GALLERY=media, 32243][/GALLERY])

1 make sure boiler is off at the electric main so boiler wont try to fire up.

2 find drain cock

3 fit hose and open cock,

4 open all air vents on radiators to let air in so system will drain properly, starting with the highest rad

5 close all air vents on rads, when drained.

6 carry out pipework

7 put recomended rust inhibitor in system via a radiator.

8 connect the filler loop

9 open filler loop, to re-fill system

10 vent all radiators, start with lowest rad

11 re open filler loop,continue filler loop and bleed until all rads done

9 switch on boiler.

do i need to check auto vent on boiler is open or close ???

also do i need to bleed the pump?

thanks again but appreciate, a final check of my checklist would be a great help.

i have attached a photo of the radiator