Hi all.

I'm replacing two old wood sheds with one brick workshop, approx 6m x 3.5m and 2.5m high.

I'm working on the basis that it's less than 30sqm and made of non-combustible materials (only roof would have wooden beams), so shouldn't bother anyone with planning and build regs issues. Hopefully not anyway as my neighbours would object to just about anything.

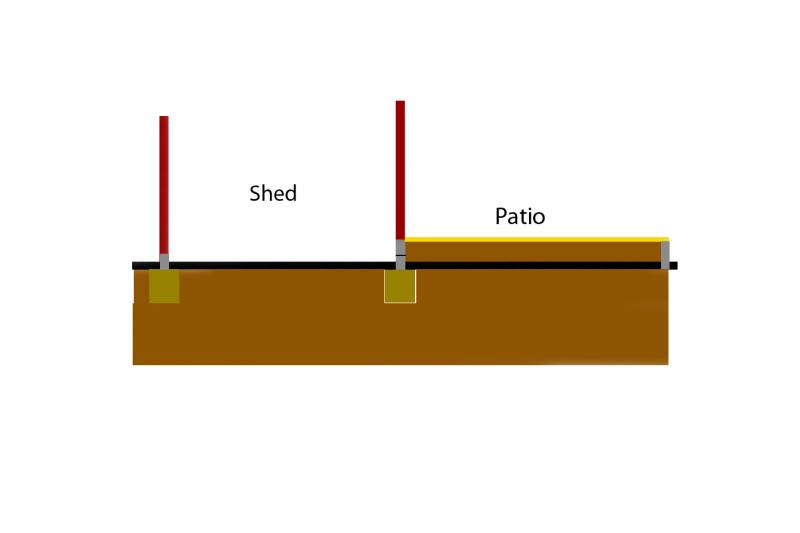

I'm also wanting to use the front of the shed partly as a retaining wall for approx 20cm of soil built up to level an area for a patio. I'd run the flagstones of the patio up against the brickwork of the shed. See attached diagram:

I'm a bit confused - I want to keep the cost down but avoid excessive ongoing maintenance so I thought I'd do strip foundations to 45cm deep x 45 wide, fill concrete to approx 20cm of surface then lay two courses of blockwork on the front (to form the retaining wall for the patio as well as the start of the shed front wall, and one course of blockwork on the other sides (to approx ground level. Having made the outline for the base, I'd then dig out the topsoil, compact & lay 150mm hardcore and 50mm sand + membrane, then pour concrete on top level with the first course of block work.

I'd also thought about instead laying a second inner blockwork channel and use block and beam construction to get the floor off the ground if easier?

Does this sound about right? I'm a bit confused as to whether you can lay bricks on top of block work, whether blockwork below ground was ok and where the DPC goes.

I don't think I can get a poured mix lorry in as the shed is at the bottom of a 100ft garden... Any guidance most gratefully received as this is the start of a scheme culminating in a Pirate ship for a toddler!

I'm replacing two old wood sheds with one brick workshop, approx 6m x 3.5m and 2.5m high.

I'm working on the basis that it's less than 30sqm and made of non-combustible materials (only roof would have wooden beams), so shouldn't bother anyone with planning and build regs issues. Hopefully not anyway as my neighbours would object to just about anything.

I'm also wanting to use the front of the shed partly as a retaining wall for approx 20cm of soil built up to level an area for a patio. I'd run the flagstones of the patio up against the brickwork of the shed. See attached diagram:

I'm a bit confused - I want to keep the cost down but avoid excessive ongoing maintenance so I thought I'd do strip foundations to 45cm deep x 45 wide, fill concrete to approx 20cm of surface then lay two courses of blockwork on the front (to form the retaining wall for the patio as well as the start of the shed front wall, and one course of blockwork on the other sides (to approx ground level. Having made the outline for the base, I'd then dig out the topsoil, compact & lay 150mm hardcore and 50mm sand + membrane, then pour concrete on top level with the first course of block work.

I'd also thought about instead laying a second inner blockwork channel and use block and beam construction to get the floor off the ground if easier?

Does this sound about right? I'm a bit confused as to whether you can lay bricks on top of block work, whether blockwork below ground was ok and where the DPC goes.

I don't think I can get a poured mix lorry in as the shed is at the bottom of a 100ft garden... Any guidance most gratefully received as this is the start of a scheme culminating in a Pirate ship for a toddler!