Hello,

We're building a 5m extension on to create a large open-plan kitchen/diner/family room. It will be 75m2, roughly 50% existing suspended timber floor + 50% new concrete slab. We're also installing an ASHP, so would like to put wet UFH in for the whole new area. We'd like to install a resin or microconcrete floor over the whole area too with a seamless finish.

I'm working with a builder who is sadly proving to be very difficult to work with - old school and not very helpful, very route one in his approach, as well as a (decent) plumber who is installing the ASHP + UFH, and a resin/microconcrete floor specialist. Sadly none of them seem willing to take control and responsibility for this so I'm stuck in the middle trying to work out what to do. It's a nightmare and causing me sleepness nights at the moment.

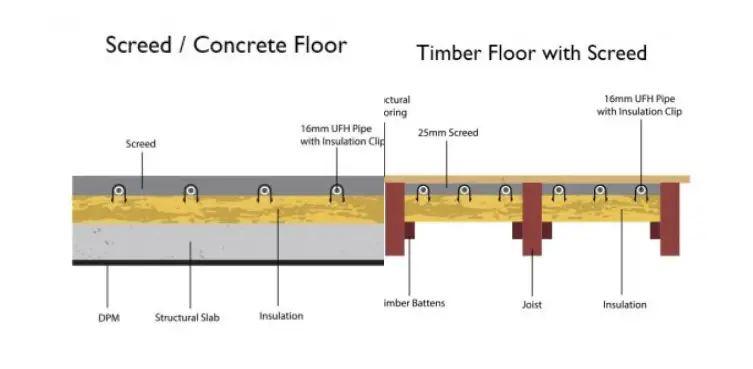

This is my current best guess for how to deal with the two halves:

On suspended side the top layer shown there would be interlocking FERMACELL 2e22 boards and the screed on the right hand half would be poured to meet this level exactly (I think?). Across the top of the entire area would then sit a thin fibreglass/epoxy layer, on to with a 3mm layer of resin or microconcrete would be poured.

The UFH will be installed with two separate loops so the different thermal characteristics of both halves can be compensated for.

Some questions:

1) Is this doable?

2) I hear that it takes screed a long time to dry enough to install these floors - up to 1 day per mm or thickness, is that true? How thick does the screed need to be?

3) Between those two areas is the outer supporting wall/threshold, what happens there?

Many thanks in advance!

We're building a 5m extension on to create a large open-plan kitchen/diner/family room. It will be 75m2, roughly 50% existing suspended timber floor + 50% new concrete slab. We're also installing an ASHP, so would like to put wet UFH in for the whole new area. We'd like to install a resin or microconcrete floor over the whole area too with a seamless finish.

I'm working with a builder who is sadly proving to be very difficult to work with - old school and not very helpful, very route one in his approach, as well as a (decent) plumber who is installing the ASHP + UFH, and a resin/microconcrete floor specialist. Sadly none of them seem willing to take control and responsibility for this so I'm stuck in the middle trying to work out what to do. It's a nightmare and causing me sleepness nights at the moment.

This is my current best guess for how to deal with the two halves:

On suspended side the top layer shown there would be interlocking FERMACELL 2e22 boards and the screed on the right hand half would be poured to meet this level exactly (I think?). Across the top of the entire area would then sit a thin fibreglass/epoxy layer, on to with a 3mm layer of resin or microconcrete would be poured.

The UFH will be installed with two separate loops so the different thermal characteristics of both halves can be compensated for.

Some questions:

1) Is this doable?

2) I hear that it takes screed a long time to dry enough to install these floors - up to 1 day per mm or thickness, is that true? How thick does the screed need to be?

3) Between those two areas is the outer supporting wall/threshold, what happens there?

Many thanks in advance!