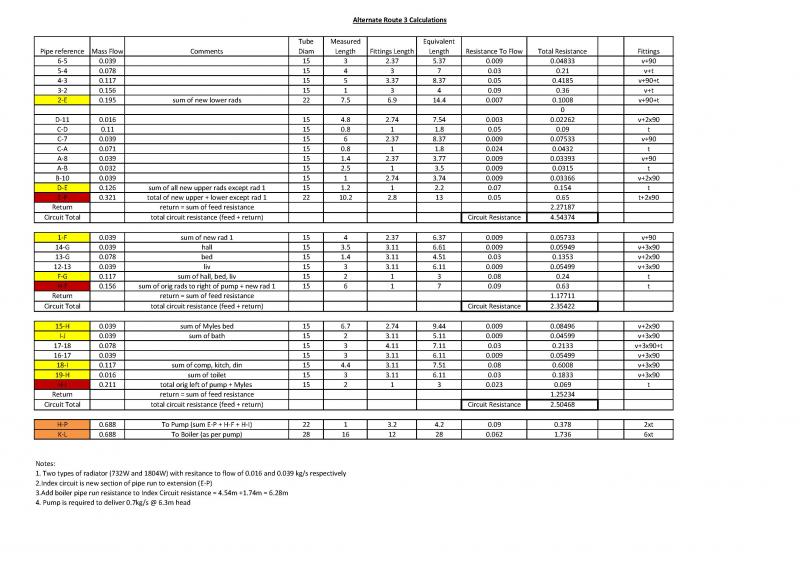

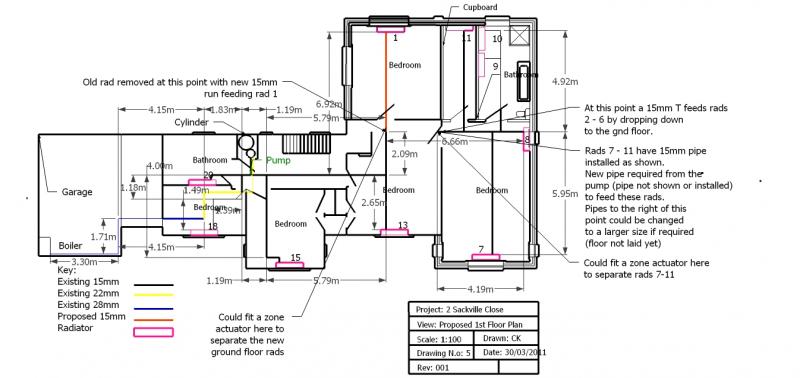

I am building an extension which consists of two storeys. At the moment I have two downstairs rooms that have been plastered and I am about to install a solid timber floor (the downstairs heating pipes sit on top of the floor slab and will be underneath the floor). The original heating system consists of a 22mm feed and return to the pump which is located on the 1st floor. The 1st floor is feed by a circuit which also feeds the ground floor radiators via a series of drops (single radiator per drop for all bar two radiators).

All existing radiators are fed via 15mm pipes and total 11 in number.

The extension sits at the far end of the house and what I have done for the ground floor is to create a circuit which is fed (via tees) from one of the existing 1st floor radiators (this radiator is now redundant and is no longer connected). The ground floor circuit feeds 5 radiators and then goes back up to the 1st floor in the extension to feed a bedroom radiator. This radiator is the last one on the circuit.

The remaining 1st floor radiators (5) in the extension are fed via a series of loops from the same tee that feeds the downstairs circuit.

At the moment I don't have any new radiators connected but I have capped off the pipes to allow me to test for leaks etc. I shut off all existing radiators and managed to get a good hot flow to the furthest new radiator location (the one that is on the 1st floor fed off of the ground floor circuit).

My questions are as follows:

1.With hindsight should I have connected the furthest radiator (1st floor) to the ground floor circuit as the water will flow down from the 1st floor round the ground circuit then up to the last radiator before dropping down again and then back up to the 1st as a return. I do have the opportunity to change this if necessary so that only the ground floor radiators are on the "ground" floor circuit - the bedroom radiator would then be connected as a loop off of the 1st floor circuit.

2.Are there likely to be issues feeding the ground floor circuit off of tees with the other side of the tees servicing the upstairs radiators (I realise that the system will need balancing).

3.Should I be ok with all radiators being serviced by 15mm pipe (as the existing ones are) or am I likely to need to upgrade to 22mm up to the point where the ground floor circuit tees off in 15mm.

4.I need to replace my existing pump as it is on its last legs - I intend to switch from a 6m head to an 8m head to cope with the larger system - are there any potential issues with this.

I realise that I have only provided limited information above and that it would have been best to ask the questions previously but I hope the above makes sense and would appreciate any comments/help.

All existing radiators are fed via 15mm pipes and total 11 in number.

The extension sits at the far end of the house and what I have done for the ground floor is to create a circuit which is fed (via tees) from one of the existing 1st floor radiators (this radiator is now redundant and is no longer connected). The ground floor circuit feeds 5 radiators and then goes back up to the 1st floor in the extension to feed a bedroom radiator. This radiator is the last one on the circuit.

The remaining 1st floor radiators (5) in the extension are fed via a series of loops from the same tee that feeds the downstairs circuit.

At the moment I don't have any new radiators connected but I have capped off the pipes to allow me to test for leaks etc. I shut off all existing radiators and managed to get a good hot flow to the furthest new radiator location (the one that is on the 1st floor fed off of the ground floor circuit).

My questions are as follows:

1.With hindsight should I have connected the furthest radiator (1st floor) to the ground floor circuit as the water will flow down from the 1st floor round the ground circuit then up to the last radiator before dropping down again and then back up to the 1st as a return. I do have the opportunity to change this if necessary so that only the ground floor radiators are on the "ground" floor circuit - the bedroom radiator would then be connected as a loop off of the 1st floor circuit.

2.Are there likely to be issues feeding the ground floor circuit off of tees with the other side of the tees servicing the upstairs radiators (I realise that the system will need balancing).

3.Should I be ok with all radiators being serviced by 15mm pipe (as the existing ones are) or am I likely to need to upgrade to 22mm up to the point where the ground floor circuit tees off in 15mm.

4.I need to replace my existing pump as it is on its last legs - I intend to switch from a 6m head to an 8m head to cope with the larger system - are there any potential issues with this.

I realise that I have only provided limited information above and that it would have been best to ask the questions previously but I hope the above makes sense and would appreciate any comments/help.