- Joined

- 20 Apr 2020

- Messages

- 4

- Reaction score

- 0

- Country

Evening, hope everyone's well.

I'm not a plumber at all, but I've worked on aircraft hydraulic systems for several years, so know my leftie loosies from my righty tighties.

First let me set the scene. Large bungalow with a standard gravity fed HW system heated by an oil fired boiler. Mains water pressure into the property is excellent, and both showers are electric units fed straight off the mains.

The problem being poor flow rate on every hot water outlet. Kitchen sink closes to the HW tank gives out 3.3L/min, and old washing machine outlet at ankle level in the garage manages 5L/min. Bathtub tap is 4L/min which means it never gets used. Mixer taps on the sinks are a nightmare to use due to the imbalance of pressure, and the cold can easily backflow down the hot pipes away from the taps.

CW tank head height is about 4m from floor level and feeds the HW tank through a 22mm pipe (which from what I've head is smaller than recommended, but I'm not prepared to doss about changing it). Visible outlet pipework is 22mm too, I'm not sure where abouts under the floor boards it steps down.

So the plan involves fitting a Salamander CT55+ pump on the outlet of the HW tank to feed the kitchen sink, two bathroom sinks, and a single bathtub. So I'm here for a quick sanity check that this is the right solution, and I'm going about it in the right way.

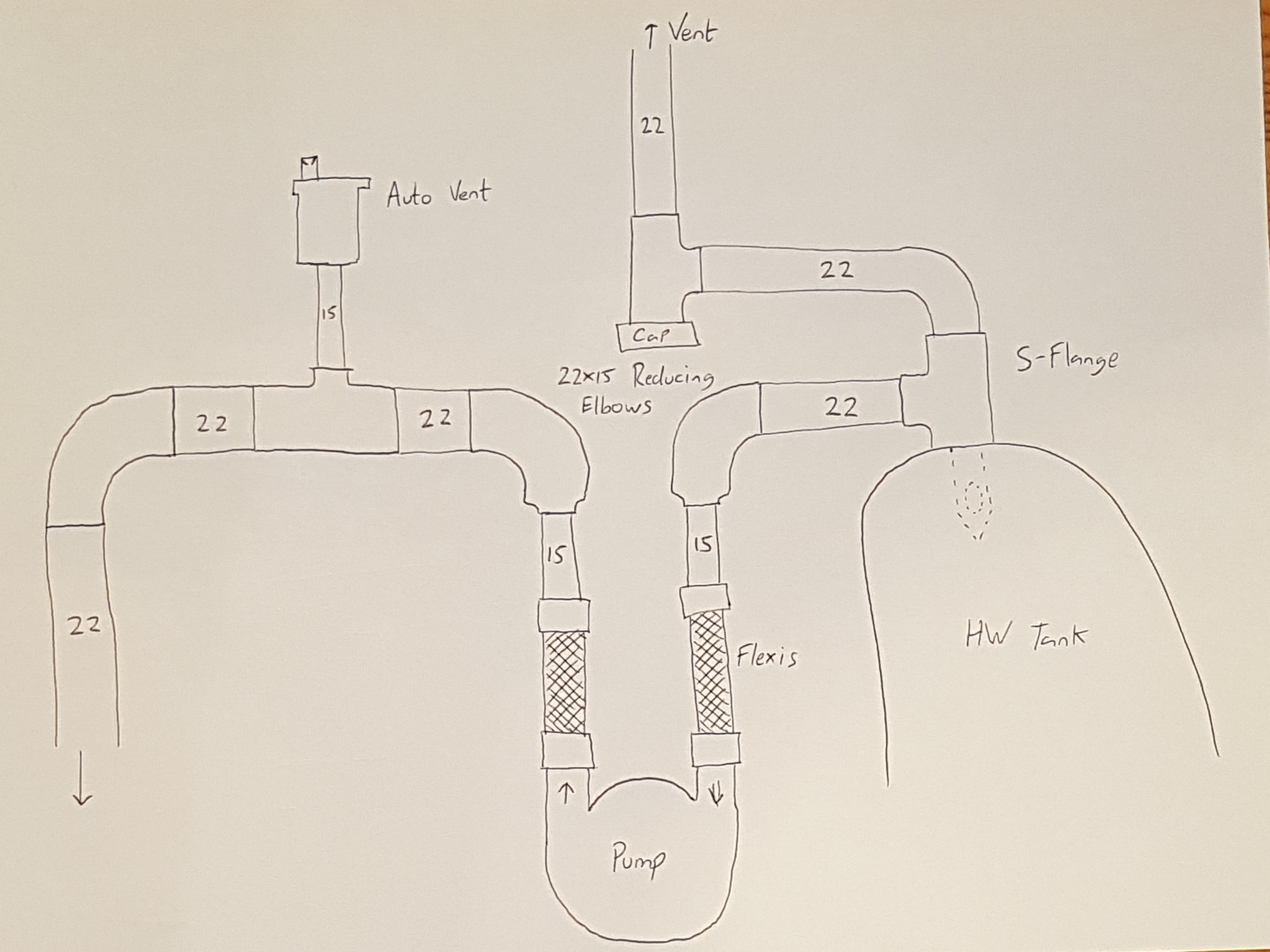

So as shown in my doodle, fit an S-Flange to the tank, disconnect and cap off the current outlet pipe leaving just the vent, reduce the 22mm outlet of the S-flange to 15mm to accept the flexis that come with the pump, increase the pipe back up to 22mm after the pump, reconnect to the outlet pipe running off to the taps, and tee an auto vent on the bend.

There's a power supply in the cupboard to run the pump off so can avoid getting a sparkie out.

Is there anything I'm overlooking or missing?

Also I'm aware that the "15mm" flexis that come with the pump will have a tiny bore. If I were to preemptively bin the warranty card, what would be the downside of running 15mm plastic pipe straight to the pump? (obviously straight and strain relieved) I could easily live with increased noise if it had a noticeably better flow rate.

Thanks in advance!

I'm not a plumber at all, but I've worked on aircraft hydraulic systems for several years, so know my leftie loosies from my righty tighties.

First let me set the scene. Large bungalow with a standard gravity fed HW system heated by an oil fired boiler. Mains water pressure into the property is excellent, and both showers are electric units fed straight off the mains.

The problem being poor flow rate on every hot water outlet. Kitchen sink closes to the HW tank gives out 3.3L/min, and old washing machine outlet at ankle level in the garage manages 5L/min. Bathtub tap is 4L/min which means it never gets used. Mixer taps on the sinks are a nightmare to use due to the imbalance of pressure, and the cold can easily backflow down the hot pipes away from the taps.

CW tank head height is about 4m from floor level and feeds the HW tank through a 22mm pipe (which from what I've head is smaller than recommended, but I'm not prepared to doss about changing it). Visible outlet pipework is 22mm too, I'm not sure where abouts under the floor boards it steps down.

So the plan involves fitting a Salamander CT55+ pump on the outlet of the HW tank to feed the kitchen sink, two bathroom sinks, and a single bathtub. So I'm here for a quick sanity check that this is the right solution, and I'm going about it in the right way.

So as shown in my doodle, fit an S-Flange to the tank, disconnect and cap off the current outlet pipe leaving just the vent, reduce the 22mm outlet of the S-flange to 15mm to accept the flexis that come with the pump, increase the pipe back up to 22mm after the pump, reconnect to the outlet pipe running off to the taps, and tee an auto vent on the bend.

There's a power supply in the cupboard to run the pump off so can avoid getting a sparkie out.

Is there anything I'm overlooking or missing?

Also I'm aware that the "15mm" flexis that come with the pump will have a tiny bore. If I were to preemptively bin the warranty card, what would be the downside of running 15mm plastic pipe straight to the pump? (obviously straight and strain relieved) I could easily live with increased noise if it had a noticeably better flow rate.

Thanks in advance!

Attachments

Last edited: