I have converted a none residential building for habitation and have had a problem with water pressure and flow rate to a shower.

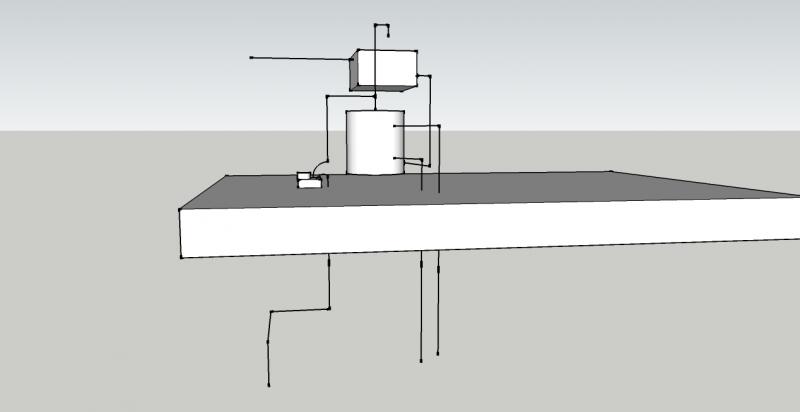

Set up is as follows.

Gravity, open vented, with indirect cylinder, with woodstove for heat source.

Some of the pipework to what is now a bathroom was already in place and run in 15mm so is not ideal for a shower on gravity system with poor head.

Also I found we had fantastically high pressure on the incoming water main and with poor flow on the hot side the shower was useless so I installed a pump on the floor at the bottom of the cylinder to the hot supply.

I chose a Stuart Turner universal single 3 bar

The problem is the pump is pulling air in from the open vent. Turner,s technical just said bleed the pump, which I did but still have the problem. The water comes through in spits and spats, like you get when you first turn a tap on after you have had the water off, but unlike a temporary supply interruption it does not clear itself, it continues all the time. I have confirmed it is air from the expansion as I have TEMPORARILY installed a valve so I can isolate the expansion, and when I do this, the pump works beautifully, open the valve again and the hot flow is rubbish again.

I am thinking I can replace this TEMPORARY valve in the expansion and install a one way valve so air cannot come down but it will still work as it should in the event of cylinder overheat. But I know this is not normal practice and there may be a cause that I cannot identify.

I could not find a way to add text to the drawing so to clarify:

The pump is on the ceiling on the left hand side of the drawing. Pipework to and from the wood stove is 28mm. The supplies to and from the Turner pump is in 22mm but this reduces to 15mm when it drops through the ceiling into the original hot flow pipework.

Set up is as follows.

Gravity, open vented, with indirect cylinder, with woodstove for heat source.

Some of the pipework to what is now a bathroom was already in place and run in 15mm so is not ideal for a shower on gravity system with poor head.

Also I found we had fantastically high pressure on the incoming water main and with poor flow on the hot side the shower was useless so I installed a pump on the floor at the bottom of the cylinder to the hot supply.

I chose a Stuart Turner universal single 3 bar

The problem is the pump is pulling air in from the open vent. Turner,s technical just said bleed the pump, which I did but still have the problem. The water comes through in spits and spats, like you get when you first turn a tap on after you have had the water off, but unlike a temporary supply interruption it does not clear itself, it continues all the time. I have confirmed it is air from the expansion as I have TEMPORARILY installed a valve so I can isolate the expansion, and when I do this, the pump works beautifully, open the valve again and the hot flow is rubbish again.

I am thinking I can replace this TEMPORARY valve in the expansion and install a one way valve so air cannot come down but it will still work as it should in the event of cylinder overheat. But I know this is not normal practice and there may be a cause that I cannot identify.

I could not find a way to add text to the drawing so to clarify:

The pump is on the ceiling on the left hand side of the drawing. Pipework to and from the wood stove is 28mm. The supplies to and from the Turner pump is in 22mm but this reduces to 15mm when it drops through the ceiling into the original hot flow pipework.