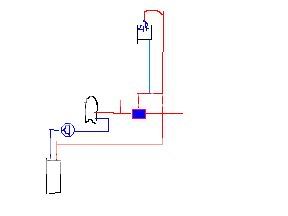

Not very good at these. System config is as picture shows. System been fine last 5 years but last week started pumping over (constant trickle) the OV and overflowing to outside.

Drained system to check Cold Feed and seems ok started to refill.

However once refilled and turned on it was ok. For a few days. Has now started again. Hw and htg work fine and turn on and off when supposed to.

If you look at pic id imagine its better practice to put CF before OV however has been fine for atleast 5 years as i said.

Any good if i were to keep the same config but put a link half way up cold feed and OV?

Could a faulty pump be causing it and how? Currently on speed 2. Didnt want to just turn it down.

Also why is it overflowing. Shouldnt the water just re-enter system after coming out of OV.

Thanks.

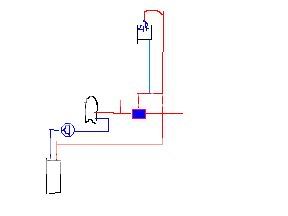

Drained system to check Cold Feed and seems ok started to refill.

However once refilled and turned on it was ok. For a few days. Has now started again. Hw and htg work fine and turn on and off when supposed to.

If you look at pic id imagine its better practice to put CF before OV however has been fine for atleast 5 years as i said.

Any good if i were to keep the same config but put a link half way up cold feed and OV?

Could a faulty pump be causing it and how? Currently on speed 2. Didnt want to just turn it down.

Also why is it overflowing. Shouldnt the water just re-enter system after coming out of OV.

Thanks.