Yesterday I baby sat while the DNO/energy supplier fitted a main isolator in advance of an overhaul of the installation and while power was off took the opportunity to disconnect and remove 2 redundant fuseboxes.

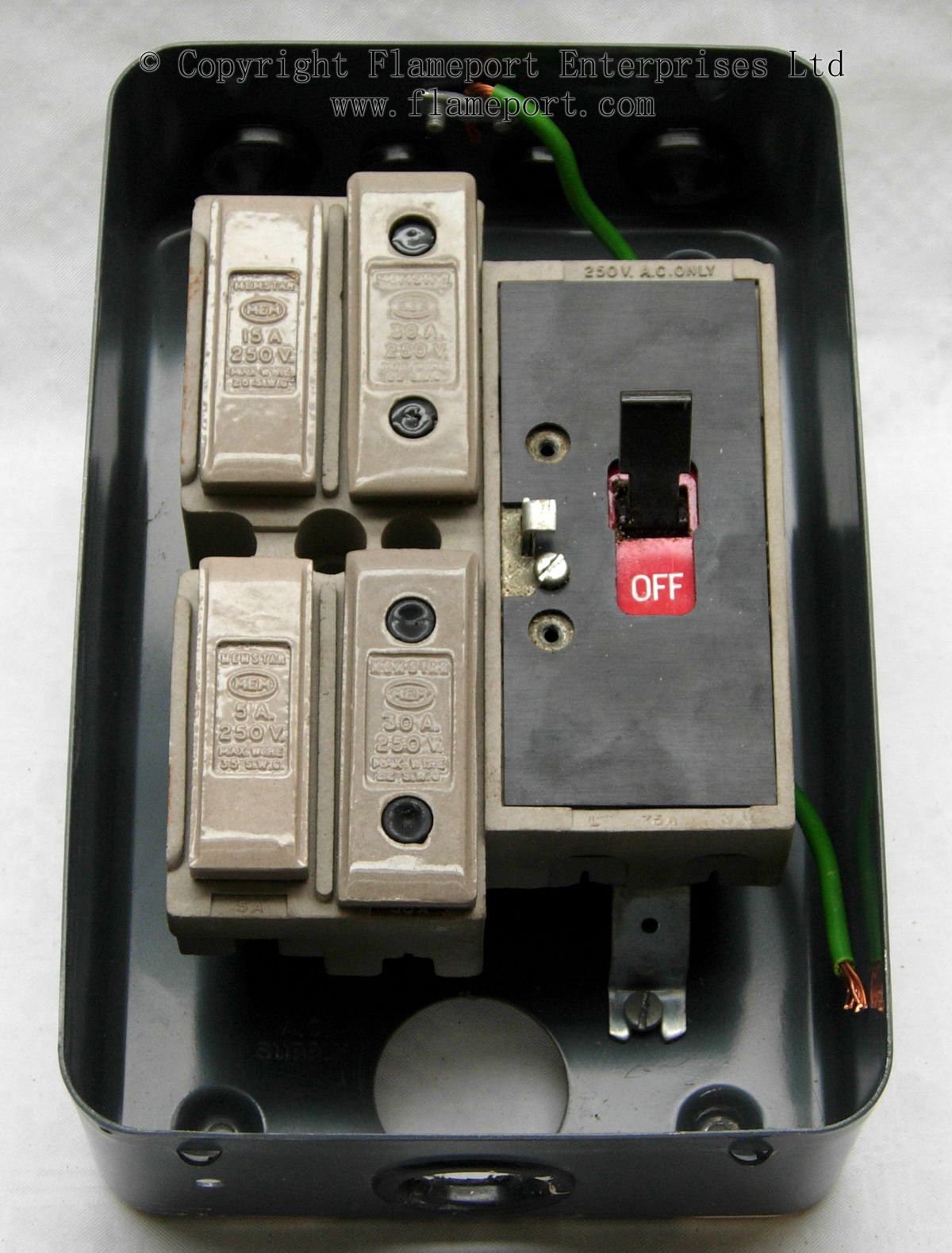

Today I got the call alleging I'd created a tripping problem on a circuit. The circuit in question looks like 7/0.044", is a 30A fuse (presumably) in one of these:

followed by a 32A RCBO in one of these:

followed by a 32A RCBO in one of these:

It has absolutely nothing to do with the work I did and checking voltages of the supply I measured 404,400,405,234,231,233. Still extremely close to yesterdays.

When I got there the RCBO was tripped. I disconnected and using a multimeter (Not wanting to risk any damage by using a meggar) I found 3MΩ between N&E, but L&E & L&N were O/C. In other words my initial test found nothing to trip the RCD.

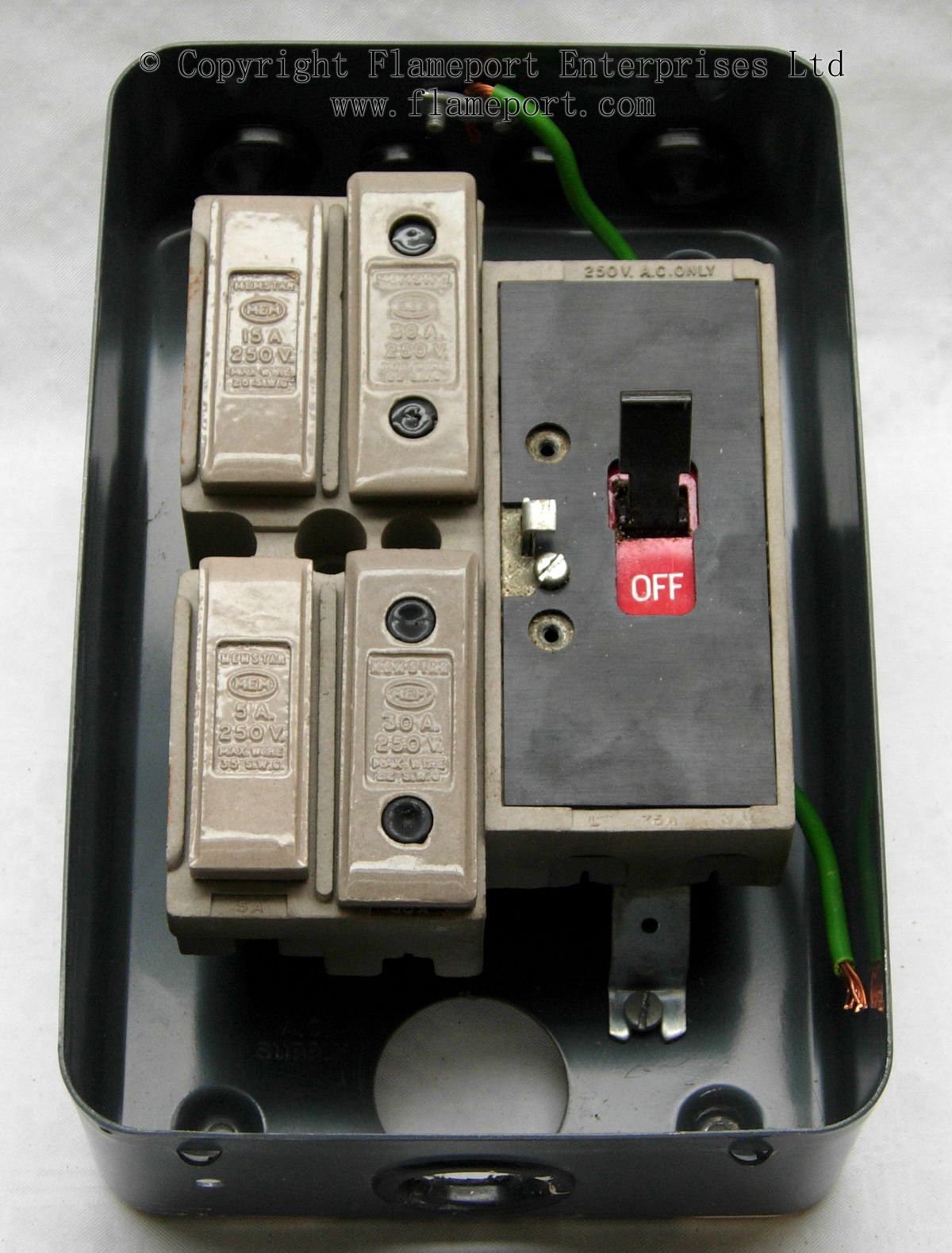

Looking at the other end of the circuit I found 3x 30A DP versions of this style of isolator:

Each supplying a bench top 2,6KW oven, more precisely these are dated lab grade units with a volume equating to about a 200mm cube. Very basic; power switch, thermostat and elements.

Each supplying a bench top 2,6KW oven, more precisely these are dated lab grade units with a volume equating to about a 200mm cube. Very basic; power switch, thermostat and elements.

We've had a number of threads, mostly about 3KW ovens, where the advice given is to wire to the typical 32A cooker circuit without any additional overload protection. This is a practice I've criticised several times but accepting it's permissable in the regs I repeated the test with all 3 ovens switched on. Still using the Lidl multimeter I had 3MΩ between N&E & L&E, and 5Ω L&N.

The bells didn't immediately ring in my head so I reterminated & repowered the circuit and just managed to measure nearly 70A with a clamp before the RCBO tripped.

Changing over to my Robin meter the loop was 3.48Ω or the 3 ovens individually 20.35Ω, 20.17Ω & 5.30Ω.

Disconnecting the offending oven I found the 1.5mm heat resisting flex:

The top pic is of the section trapped between a tubular metal leg and sawn wood shelf upright, the cable still meggars OK. The heating element measures 5.1Ω

Today I got the call alleging I'd created a tripping problem on a circuit. The circuit in question looks like 7/0.044", is a 30A fuse (presumably) in one of these:

It has absolutely nothing to do with the work I did and checking voltages of the supply I measured 404,400,405,234,231,233. Still extremely close to yesterdays.

When I got there the RCBO was tripped. I disconnected and using a multimeter (Not wanting to risk any damage by using a meggar) I found 3MΩ between N&E, but L&E & L&N were O/C. In other words my initial test found nothing to trip the RCD.

Looking at the other end of the circuit I found 3x 30A DP versions of this style of isolator:

We've had a number of threads, mostly about 3KW ovens, where the advice given is to wire to the typical 32A cooker circuit without any additional overload protection. This is a practice I've criticised several times but accepting it's permissable in the regs I repeated the test with all 3 ovens switched on. Still using the Lidl multimeter I had 3MΩ between N&E & L&E, and 5Ω L&N.

The bells didn't immediately ring in my head so I reterminated & repowered the circuit and just managed to measure nearly 70A with a clamp before the RCBO tripped.

Changing over to my Robin meter the loop was 3.48Ω or the 3 ovens individually 20.35Ω, 20.17Ω & 5.30Ω.

Disconnecting the offending oven I found the 1.5mm heat resisting flex:

The top pic is of the section trapped between a tubular metal leg and sawn wood shelf upright, the cable still meggars OK. The heating element measures 5.1Ω