Morning all,

Every time I touch anything on this house I uncover interesting things.

Roof Part 2. Place was reroofed about 20 years ago I suspect by a builder (mortar work looked very good but has all cracked with age surprise surprise, roofing work looked a bit poor and I've discovered is not to the manufacturers' specs for Marley Eternit).

I'm going to lift the slates, battens and felt and relay with correct lap, gauge etc but have hit a snag at the eaves. Hopefully the section attached will make sense.

View media item 72341

The rafters sit directly on the penultimate course of bricks on the front wall

This means (at the moment) the felt is virtually flat for half the thickness of the wall which explains a lot in terms of the wall being damp

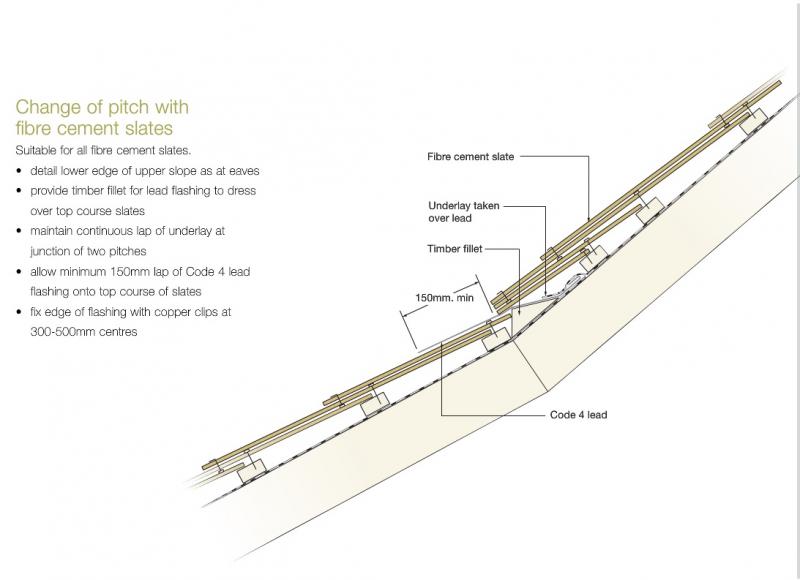

When I strip everything off (the rafters and purlins are in very good nick by the way- all solid on this side of the roof, even the one I've uncovered here), what is the best way to get some fall into the eaves? I'm thinking either counterbattening the whole roof with 2 x 2 (which will cost and be annoying but at least give me an even roof pitch) or making some sort of double wedge pieces out of 2 x 2 for the lower 200mm of rafter/top of the wall (which will be fiddly and give a pitch change) or I could just run 500mm or so of OSB or ply from behind the bargeboard up the roof (easy but again gives a pitch change plus might give problems with ponding in the membrane). Any other thoughts? (And please don't say knock it down and start again!)

No real hurry on this- not going to chance the scaffold until April!

Cheers

Every time I touch anything on this house I uncover interesting things.

Roof Part 2. Place was reroofed about 20 years ago I suspect by a builder (mortar work looked very good but has all cracked with age surprise surprise, roofing work looked a bit poor and I've discovered is not to the manufacturers' specs for Marley Eternit).

I'm going to lift the slates, battens and felt and relay with correct lap, gauge etc but have hit a snag at the eaves. Hopefully the section attached will make sense.

View media item 72341

The rafters sit directly on the penultimate course of bricks on the front wall

This means (at the moment) the felt is virtually flat for half the thickness of the wall which explains a lot in terms of the wall being damp

When I strip everything off (the rafters and purlins are in very good nick by the way- all solid on this side of the roof, even the one I've uncovered here), what is the best way to get some fall into the eaves? I'm thinking either counterbattening the whole roof with 2 x 2 (which will cost and be annoying but at least give me an even roof pitch) or making some sort of double wedge pieces out of 2 x 2 for the lower 200mm of rafter/top of the wall (which will be fiddly and give a pitch change) or I could just run 500mm or so of OSB or ply from behind the bargeboard up the roof (easy but again gives a pitch change plus might give problems with ponding in the membrane). Any other thoughts? (And please don't say knock it down and start again!)

No real hurry on this- not going to chance the scaffold until April!

Cheers