I have a 6m x 5m garage which I’m planning to use as a workshop for tinkering on cars, playing music, etc.. To keep noise down, I’m planning on building a sealed, timber framed room-within-a-room, clad with a layer of OSB and a layer of plasterboard. The idea being that noise generated in the inside room won’t be transferred to the outer structure.

It's under 30m^2 so I don't need building control approval, but I'd like to make sure the construction is safe.

The new internal wall will be a 2x4 stud wall, bolted to the floor but my issue is the ceiling.

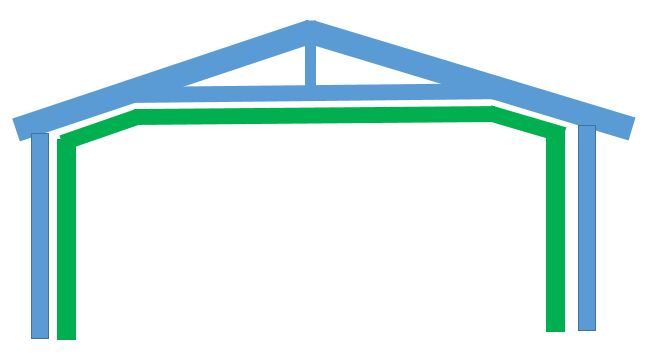

Normally you would run the internal room’s ceiling joists horizontally between the two top plates of the stud walls, tying everything together and stopping the outer walls ‘bowing out’ in the middle. However, the trusses which make up the ceiling of my garage are raised tie, so there’s sloped sections at the side (900mm horizontally out from the wall, 450mm vertically) and higher headroom in the middle of the room which I need to keep.

Span tables suggest that at 400mm centres, I can use 8x2 joists to span the 5m gap. Is there a way I can make up ceiling joists which have angled sections which can span the gap? Could I join the angled sections to the main horizontal section with 2-3mm thick steel plates and lag bolts?

If I start beefing things up to that extent, will my 2x4 stud wall be able to cope with the weight of the joists, plus OSB and plasterboard?

All help appreciated!

It's under 30m^2 so I don't need building control approval, but I'd like to make sure the construction is safe.

The new internal wall will be a 2x4 stud wall, bolted to the floor but my issue is the ceiling.

Normally you would run the internal room’s ceiling joists horizontally between the two top plates of the stud walls, tying everything together and stopping the outer walls ‘bowing out’ in the middle. However, the trusses which make up the ceiling of my garage are raised tie, so there’s sloped sections at the side (900mm horizontally out from the wall, 450mm vertically) and higher headroom in the middle of the room which I need to keep.

Span tables suggest that at 400mm centres, I can use 8x2 joists to span the 5m gap. Is there a way I can make up ceiling joists which have angled sections which can span the gap? Could I join the angled sections to the main horizontal section with 2-3mm thick steel plates and lag bolts?

If I start beefing things up to that extent, will my 2x4 stud wall be able to cope with the weight of the joists, plus OSB and plasterboard?

All help appreciated!