I think I have a problem with my plans the RSJ I'm using to support my rafters. Although my SE has proved it will take the loadings, the designer (me) didn't fully think through the installation in terms of rotational support.

The thought process was as follows:

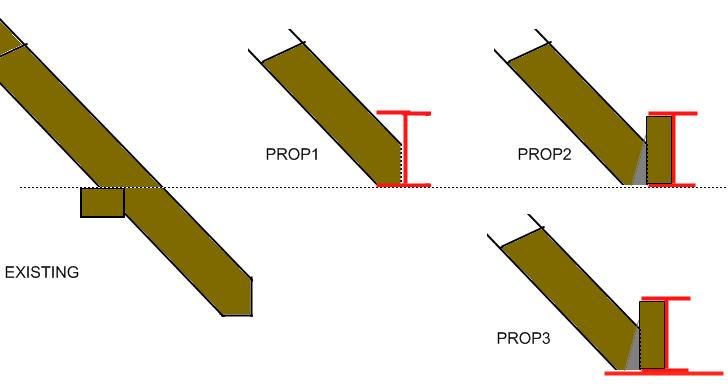

In 'existing' on the diagram below, the rafter sits on the wall plate.

Proposed1 shows the initial concept where the rafters are trimmed at wall plate level then the existing birdsmouth is sat on the bottom flange of the RSJ.

Proposed2 is a progression on this concept to bolt a captive wooden joist into the RSJ so that hangers can be used, rather than having to fix noggins between every rafter.

This is where the problem lies. Because this joist is up at wall plate level there will be very little masonry to stop any downward force from the rafter feet rotating the joist counter-clockwise as you look at it.

So perhaps I should have asked the steel firm to have welded a couple of large feet to the joist as per Proposed3. But it's too late now.

So I want to return to Proposed1. Can I fix noggins between the rafters using framing anchors, or will each 400mm noggin need to be bolted in place?

Thanks as always!

The thought process was as follows:

In 'existing' on the diagram below, the rafter sits on the wall plate.

Proposed1 shows the initial concept where the rafters are trimmed at wall plate level then the existing birdsmouth is sat on the bottom flange of the RSJ.

Proposed2 is a progression on this concept to bolt a captive wooden joist into the RSJ so that hangers can be used, rather than having to fix noggins between every rafter.

This is where the problem lies. Because this joist is up at wall plate level there will be very little masonry to stop any downward force from the rafter feet rotating the joist counter-clockwise as you look at it.

So perhaps I should have asked the steel firm to have welded a couple of large feet to the joist as per Proposed3. But it's too late now.

So I want to return to Proposed1. Can I fix noggins between the rafters using framing anchors, or will each 400mm noggin need to be bolted in place?

Thanks as always!