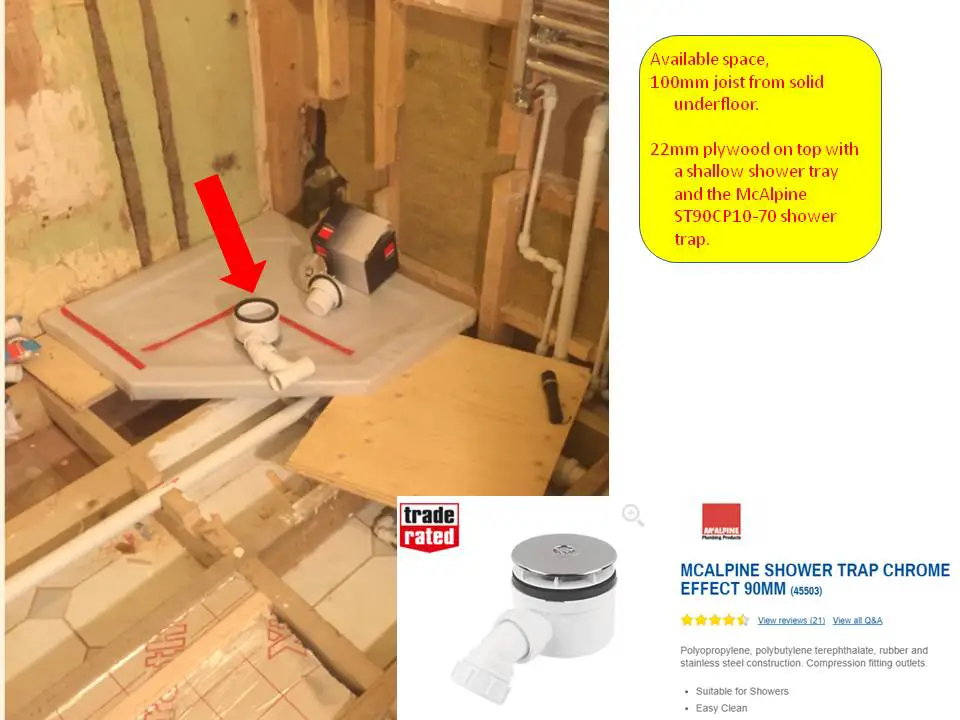

In a new downstairs utility/shower room I have a shower tray waste to route below plywood floor into solvent weld 32mm new pipe. Acess is limited beneath by solid underfloor with 100mm joist floor and 22mm plywood floor.

I have bought the MacAlpine ST90CP10-70 shower trap, see photos, because it is rated as a good one. I didn't want to use the free one supplied with the tray which looked flimsy and already had the thread crossed.

>> Note - I intentionally want to keep the tray close to the floor because it is for easy near-level access showering. I want to avoid building up a structure beneath the tray.

>Pipework routing - I have a number of options to route this but have to consider dropping the tray in and probably doing all the sealing and tightening up from above, which I have seen done in a couple of videos.

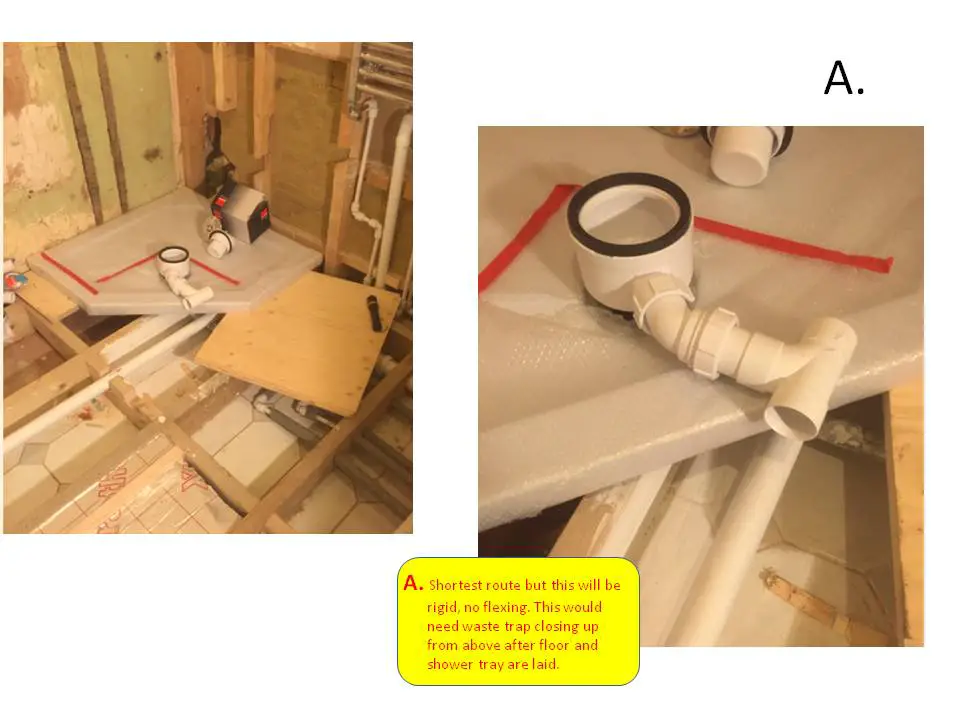

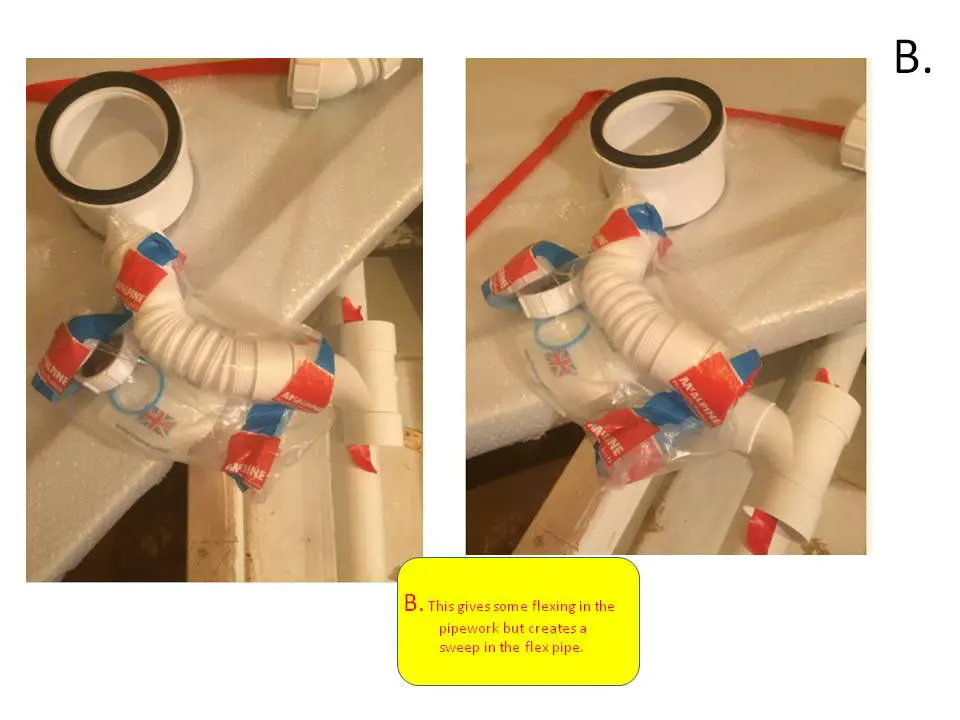

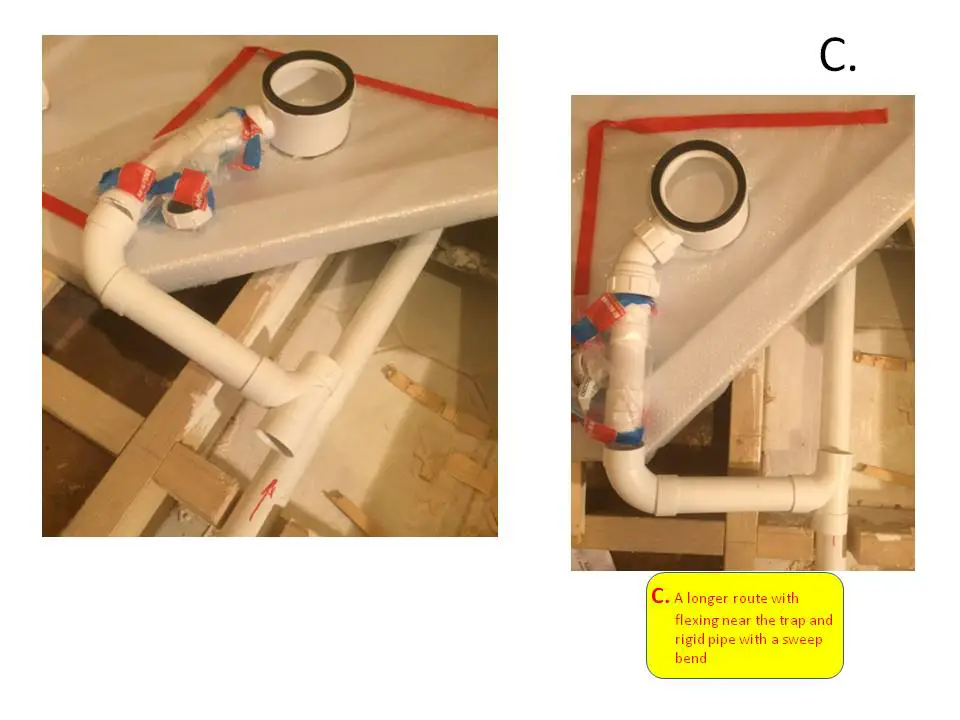

I have shown three suggestions A, B & C in the photos and, although A is the shortest and probably least likely to present leak problems in the future (?), it is also rigid and if dropping the tray on from above, it offers little/no room for adjustment.

Suggestions please and your view on which, if any of these I should go for.

> Sealing - Should I use a sealant/silicone around the rubber seals when fitting?

I understand that it would need to be a neutral cure to not affect the rubber seals.

> Mortar bed under tray? - this tray is very thick GRP and robust, plus it is extremely close to the floor - 15mm bottom of tray to underfloor.

Do I need to bed it in on mortar? It is not a resin & sand type already filled.

Maybe sounds crazy but could expanding foam be used to fill the void - taking care not to gunge up the waste trap?

All suggestions gratefully received.

I have bought the MacAlpine ST90CP10-70 shower trap, see photos, because it is rated as a good one. I didn't want to use the free one supplied with the tray which looked flimsy and already had the thread crossed.

>> Note - I intentionally want to keep the tray close to the floor because it is for easy near-level access showering. I want to avoid building up a structure beneath the tray.

>Pipework routing - I have a number of options to route this but have to consider dropping the tray in and probably doing all the sealing and tightening up from above, which I have seen done in a couple of videos.

I have shown three suggestions A, B & C in the photos and, although A is the shortest and probably least likely to present leak problems in the future (?), it is also rigid and if dropping the tray on from above, it offers little/no room for adjustment.

Suggestions please and your view on which, if any of these I should go for.

> Sealing - Should I use a sealant/silicone around the rubber seals when fitting?

I understand that it would need to be a neutral cure to not affect the rubber seals.

> Mortar bed under tray? - this tray is very thick GRP and robust, plus it is extremely close to the floor - 15mm bottom of tray to underfloor.

Do I need to bed it in on mortar? It is not a resin & sand type already filled.

Maybe sounds crazy but could expanding foam be used to fill the void - taking care not to gunge up the waste trap?

All suggestions gratefully received.