Hello,

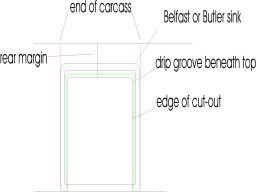

I am in the process of fitting out kitchen. We have purchased the solid oak worktops from IKEA and have a Butler sink with a large mixer tap from MFI. I am just after some tips, a: for cutting these worktops as they are block wood rather than sawn sheets and b: what's the best way to get the sink in the right place as the worktop hangs over the sides and back of the sink??

Thanks for any advice!!

I am in the process of fitting out kitchen. We have purchased the solid oak worktops from IKEA and have a Butler sink with a large mixer tap from MFI. I am just after some tips, a: for cutting these worktops as they are block wood rather than sawn sheets and b: what's the best way to get the sink in the right place as the worktop hangs over the sides and back of the sink??

Thanks for any advice!!