So I'm installing 4 steel beams for my loft conversion, and I'm pretty much up to all of it apart from the actual manoeuvring of the beam into the pocket and onto the bearer plate.

The problem is, the wall span is 4650mm and the part walls either side are 150mm depth. This is a total of 4950mm. The steel beams by the structural engineer are to be 4800mm. We're in a mid terraced property so we are not able to cut into the wall more than 150mm.

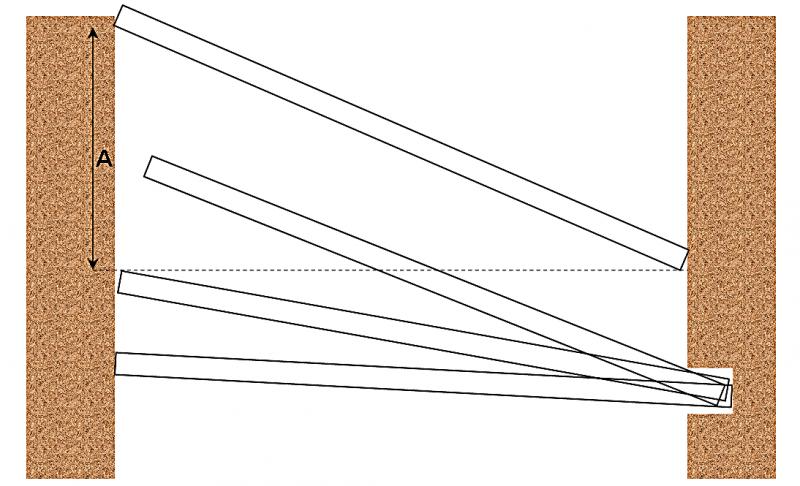

When the crane is lifting in the beams, how are they going to be able to be inserted if the face of the party walls are narrower than the steel. The beam will get stuck as it's being turned into place. Right?

I got some instructions from the Party Wall Surveyor (who our difficult neighbours made us employ - has cost us a fortune) and he has said this...

3. On the non-chimney breast side, form a recess in the party wall half a brick deep (up to the centre of the party wall line) 1000 mm wide and 6 courses high for a pocket to allow steels to be angled into position and the spreader plate inserted.

4. On the chimney breast side, form a recess in the party wall half a brick deep (up to the centre of the party wall line) 500 wide (or the width of the specified steel spreader plate) and 6 courses high for the support pocket.

The depths of the property is only 7 meters, and cutting out that much brickwork from the wall is surely incredibly unsafe?! The ridge beam is no problem, however, the three floor beams are within very close proximity of each other, and cutting out that much of the brickwork will leave a large amount of brickwork above the cut-out exposed.

Is there an alternative - apart from cutting the beams in half. I hope there's someone out there who can help!!!

Regards.

The problem is, the wall span is 4650mm and the part walls either side are 150mm depth. This is a total of 4950mm. The steel beams by the structural engineer are to be 4800mm. We're in a mid terraced property so we are not able to cut into the wall more than 150mm.

When the crane is lifting in the beams, how are they going to be able to be inserted if the face of the party walls are narrower than the steel. The beam will get stuck as it's being turned into place. Right?

I got some instructions from the Party Wall Surveyor (who our difficult neighbours made us employ - has cost us a fortune) and he has said this...

3. On the non-chimney breast side, form a recess in the party wall half a brick deep (up to the centre of the party wall line) 1000 mm wide and 6 courses high for a pocket to allow steels to be angled into position and the spreader plate inserted.

4. On the chimney breast side, form a recess in the party wall half a brick deep (up to the centre of the party wall line) 500 wide (or the width of the specified steel spreader plate) and 6 courses high for the support pocket.

The depths of the property is only 7 meters, and cutting out that much brickwork from the wall is surely incredibly unsafe?! The ridge beam is no problem, however, the three floor beams are within very close proximity of each other, and cutting out that much of the brickwork will leave a large amount of brickwork above the cut-out exposed.

Is there an alternative - apart from cutting the beams in half. I hope there's someone out there who can help!!!

Regards.