I take it your a structural engineer then?

I've got a good grounding in engineering in general, just self-training in structural for this one. And figure there's no harm in going a bit over kill to ensure what I have IS strong enough.

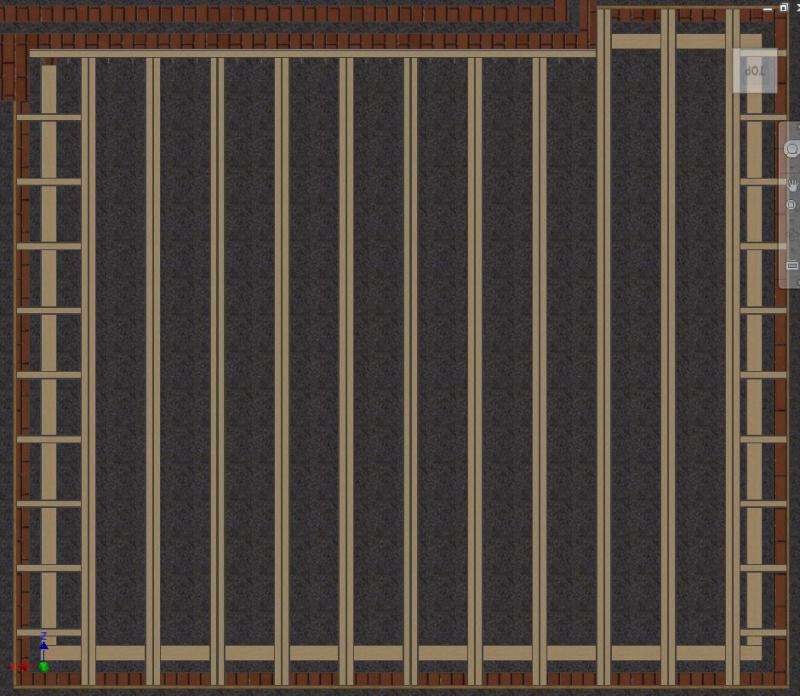

It'll be a marked improvement on what I have at the moment which is a rotting heap of compost (literally is that in places, pics to follow).

The over 10kN for tensile is based on the steel failure rate, not the brick. the studding will be the last thing to go out of anything else, penny washered and nylocked on.

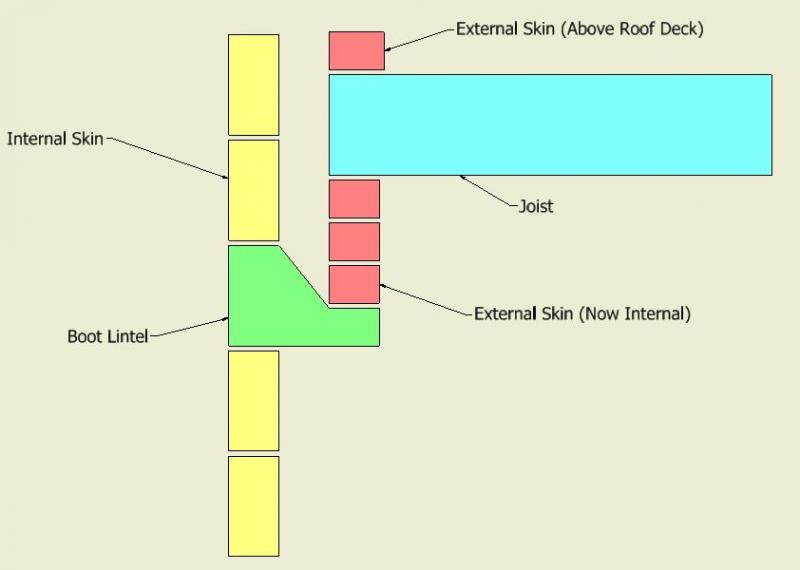

Reason for steel behind the ledger is that the roof is currently build into a wall over the toe of a boot lintel with no additional support. So there are 5 joists resting on the cantilevered lintel that should have been upgraded during the original build. But budget doesn't extend to fixing that now.

Boot Lintel

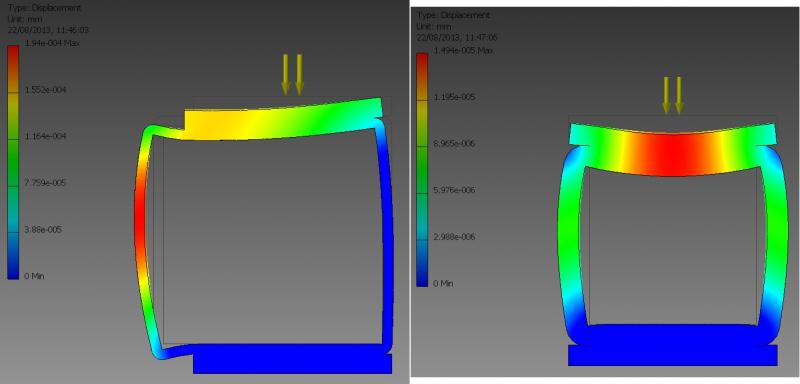

Assuming a worst case failure of that lintel (so the ledger is unsupported for a 2m length in the middle. The steel is the difference between a 3.8mm defelection and a 0.7mm. Again, probably over kill, but it does mitigate the lack of proper lintel.

Reason for resin over any sort of expanding anchour system is because the wall was excesivly damaged when the old joists were installed. There is also a door frame just above the roof, so only about 3-4 rows of bricks above fixings. Compressive strength will be fine as the ledger will be attached below the position of the old joists, but I'm a bit dubious about the tensile strength and don't want to risk splitting the brickwork.

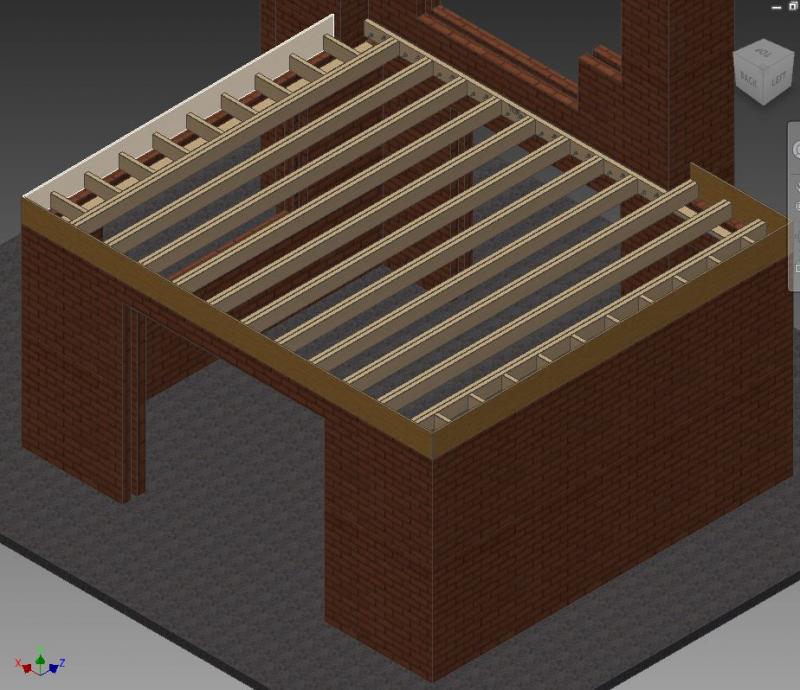

Note door above flat roof.

And I wouldn't do that Tony... Well, any time soon. I was looking into a distance learning course

Fubar.

I've got a good grounding in engineering in general, just self-training in structural for this one. And figure there's no harm in going a bit over kill to ensure what I have IS strong enough.

It'll be a marked improvement on what I have at the moment which is a rotting heap of compost (literally is that in places, pics to follow).

The over 10kN for tensile is based on the steel failure rate, not the brick. the studding will be the last thing to go out of anything else, penny washered and nylocked on.

Reason for steel behind the ledger is that the roof is currently build into a wall over the toe of a boot lintel with no additional support. So there are 5 joists resting on the cantilevered lintel that should have been upgraded during the original build. But budget doesn't extend to fixing that now.

Boot Lintel

Assuming a worst case failure of that lintel (so the ledger is unsupported for a 2m length in the middle. The steel is the difference between a 3.8mm defelection and a 0.7mm. Again, probably over kill, but it does mitigate the lack of proper lintel.

Reason for resin over any sort of expanding anchour system is because the wall was excesivly damaged when the old joists were installed. There is also a door frame just above the roof, so only about 3-4 rows of bricks above fixings. Compressive strength will be fine as the ledger will be attached below the position of the old joists, but I'm a bit dubious about the tensile strength and don't want to risk splitting the brickwork.

Note door above flat roof.

And I wouldn't do that Tony... Well, any time soon. I was looking into a distance learning course

Fubar.