We recently had a kitchen extension done to our Edwardian house and went with suspended timber floors so we could run exposed floorboards through the house to match the other rooms. We had no issues until the kitchen was fitted and heavy quartz worktops installed last week, and now suddenly the kitchen is like a trampoline- everything on surfaces rattles when someone walks through the room, and you can feel the vibrations across the room. I saw everything being built and whilst it’s passed BC and generally looked ok, my suspicion is the span of the joists (3.7m) might have been a bit long and there should have been a supporting wall mid way.

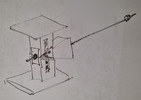

We’ve had some issues with the builders and don’t think we’ll be getting them back so I’m hoping to to try and deal with this myself. The floor is all sanded and finished and the kitchen fitted and worktops in place so lifting the floor all up isn’t really an option now and there is no crawl space underneath,bexceps about a foot or air under the joists, so I was thinking that perhaps we could lift the central three or so floorboards to gain access to the underneath (these thankfully don’t run under the kitchen except a bit that’s under the island). Then I was wondering if we could perhaps hammer something like CLS studwork timber supports between the earth sub-floor and the joists, under tension (perhaps jacking up with a car Jack first?). I have a feeling digging a concrete foundation for these would be good but this might be hard to do within a restricted space, so was thinking maybe laying a paving slab under each support to spread the load on the floor. Does this sound like a feasible plan to reduce the bounce, given the restricted space we’ll be working in?

We’ve had some issues with the builders and don’t think we’ll be getting them back so I’m hoping to to try and deal with this myself. The floor is all sanded and finished and the kitchen fitted and worktops in place so lifting the floor all up isn’t really an option now and there is no crawl space underneath,bexceps about a foot or air under the joists, so I was thinking that perhaps we could lift the central three or so floorboards to gain access to the underneath (these thankfully don’t run under the kitchen except a bit that’s under the island). Then I was wondering if we could perhaps hammer something like CLS studwork timber supports between the earth sub-floor and the joists, under tension (perhaps jacking up with a car Jack first?). I have a feeling digging a concrete foundation for these would be good but this might be hard to do within a restricted space, so was thinking maybe laying a paving slab under each support to spread the load on the floor. Does this sound like a feasible plan to reduce the bounce, given the restricted space we’ll be working in?