Aa

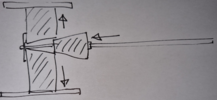

the bit I’m struggling with is the timber post cut so there is a folding wedge. What hinges it?I think you'd need to experiment to get the best design, but essentially a wooden post cut so there is a folding wedge, a plate top and bottom to spread the load and make it so it doesn't topple over, and a threaded rod (which you can buy from the builder's/engineers merchants in various lengths) which with various lock nuts/welded nuts, washers and a bit of bracketry will close the wedges and raise the jack when turned with a spanner on the end. The wedge post will be very solid when raised.

Think I'd think about getting a 75x75 or 100x100 treated fence post to cut up. If you cut them to height so the wedge is 80-90% home when raised in the correct position, you'll get a very solid support. You'll need something to keep the top and bottom bit's of the post in line - bit of ingenuity needed - depends what access to tools you have.

Or even buy a few really cheap scissor jacks, and modify them so you can easily position them without toppling over. https://www.amazon.co.uk/Quality-Tonne-Scissor-Handle-Octavia/dp/B0721MSB52/ref=sr_1_97?crid=2XIGJI4LTSBDC&keywords=wedge+jacks&qid=1687162421&sprefix=wedge+jacks,aps,76&sr=8-97