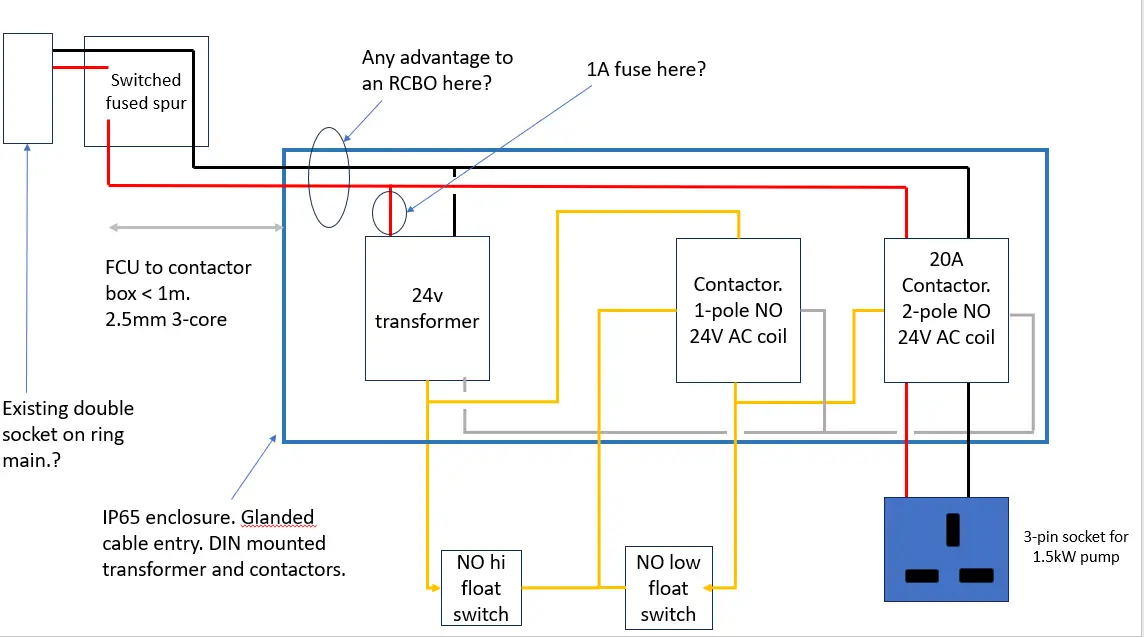

This is a little different - I want to build a small control circuit to turn on flood pumps when a high level float switch is tripped, and leave the pump on until the low level switch is broken. I figure this can be done with a couple of contactors inside an enclosure and feeding a regular (outdoor) 13A socket.

My first stab at a concept is below.

Things to note:

- I know pumps come with float switches pre-wired, but the pit depth means long tethers to avoid short cycling the pump and the possibility of snagging the float is too high. Hence this need to build 'fixed' switches to turn on the pump.

- I know I could wire the pump directly into the 20A contactor, but it is important to be able to swap pumps easily.

- The installation will be under an open barn roof, so weather protected. The existing ring main looks to be DIY wired. I haven't been able to check yet, (not my barn) but I am assuming it does come off a 30 year old CU in the workshop that is RCD protected.

Questions I know I would like some advice on. There are probably others things I don't yet know I need advice on, so please chip in if this looks plain stupid:

1) Is this 'allowed' to introduce some home brew switching circuit upstream of a 13A socket?

2) I feel better using 24V on the float switches, although they are rated to 240v, and using 240v would remove the need for transformer and first contactor (changing the second one to 240v coil). Is this practical to step down for switching?

3) Should I fuse the transformer?

4) Would an RCBO inside the enclosure be good practice? Can't be easily reset though, so probably not, even before I get into the difficulty of sizing it.

5) What am I missing?

My first stab at a concept is below.

Things to note:

- I know pumps come with float switches pre-wired, but the pit depth means long tethers to avoid short cycling the pump and the possibility of snagging the float is too high. Hence this need to build 'fixed' switches to turn on the pump.

- I know I could wire the pump directly into the 20A contactor, but it is important to be able to swap pumps easily.

- The installation will be under an open barn roof, so weather protected. The existing ring main looks to be DIY wired. I haven't been able to check yet, (not my barn) but I am assuming it does come off a 30 year old CU in the workshop that is RCD protected.

Questions I know I would like some advice on. There are probably others things I don't yet know I need advice on, so please chip in if this looks plain stupid:

1) Is this 'allowed' to introduce some home brew switching circuit upstream of a 13A socket?

2) I feel better using 24V on the float switches, although they are rated to 240v, and using 240v would remove the need for transformer and first contactor (changing the second one to 240v coil). Is this practical to step down for switching?

3) Should I fuse the transformer?

4) Would an RCBO inside the enclosure be good practice? Can't be easily reset though, so probably not, even before I get into the difficulty of sizing it.

5) What am I missing?