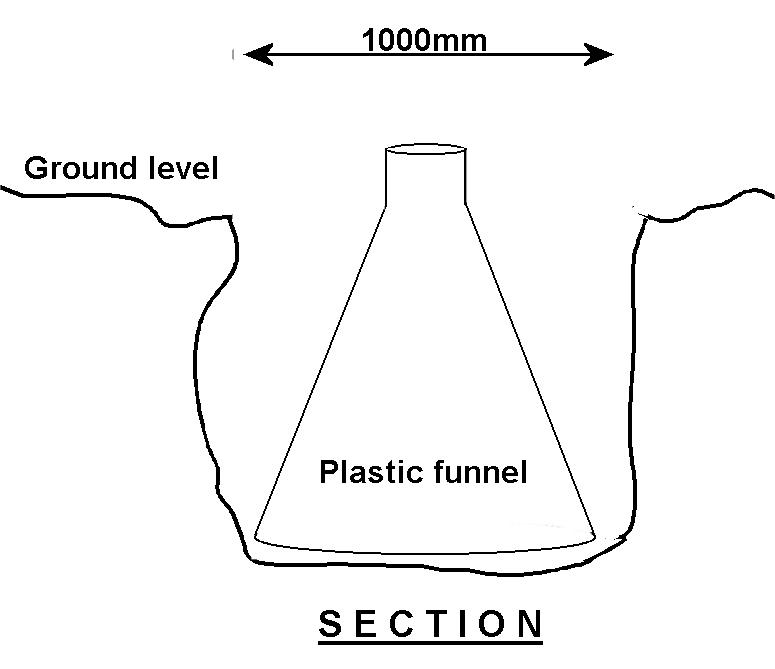

In a TV building programme I saw a system for placing structural posts - to support a biggish veranda for a house, I think. They drilled a 1m hole with a motorised auger, put a large inverted plastic funnel in the hole, poured concrete into the funnel, pushed a steel post down into the concrete in the funnel and back-filled. Quick, accurate, stable and economical.

Has anyone else seen this? What do you call the plastic funnels and/or this system? Where can I get more information?

Structural post system

An inverted plastic funnel is placed in a hole; concrete is poured into the funnel; a post is...

Has anyone else seen this? What do you call the plastic funnels and/or this system? Where can I get more information?