As per thread title.

Q: Legally, How often do you have to get your test instruments calibrated ?

Q: What is considered to be good practice for an instrument that is used infrequently ?

I know that the calibtation houses will recommend that they are done annually , however they are running a business and so even though it is probably a good idea, I would expect them to say that , (for the return business) anyway.

We will all know that an instrument can only really be considered accurate at the exact moment of calibration anyway.

At my work place we usually get at least one internal audit by the Quality Manager and the senior Maintenance Manager and at least 1 or 2 external quality audits by the CAA ( Civil Aviation Authority) per year to ensure we are maintaining at least the minimum required standards. The Instrument & tool calibration register is something that always gets close scrutiny.

Needless to say any time i 'really' need to use a specific tool it will be away on Cal too

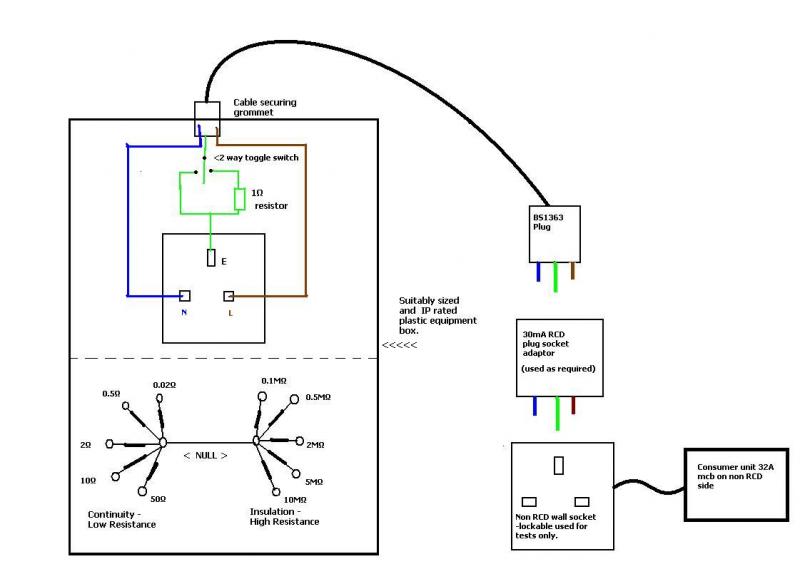

I have just bought a brand new RCD tester and s/h Loop tester (annual cal expired 19 dec 2007) and a s/h Cont/Ins tester which hasn't arrived yet, but is out of cal too. These will be used for private/Home/DIY/ Personal interest purposes - not professional

so just asking out of interest really.

Q: Legally, How often do you have to get your test instruments calibrated ?

Q: What is considered to be good practice for an instrument that is used infrequently ?

I know that the calibtation houses will recommend that they are done annually , however they are running a business and so even though it is probably a good idea, I would expect them to say that , (for the return business) anyway.

We will all know that an instrument can only really be considered accurate at the exact moment of calibration anyway.

At my work place we usually get at least one internal audit by the Quality Manager and the senior Maintenance Manager and at least 1 or 2 external quality audits by the CAA ( Civil Aviation Authority) per year to ensure we are maintaining at least the minimum required standards. The Instrument & tool calibration register is something that always gets close scrutiny.

Needless to say any time i 'really' need to use a specific tool it will be away on Cal too

I have just bought a brand new RCD tester and s/h Loop tester (annual cal expired 19 dec 2007) and a s/h Cont/Ins tester which hasn't arrived yet, but is out of cal too. These will be used for private/Home/DIY/ Personal interest purposes - not professional

so just asking out of interest really.